Method and equipment for improving desulfurization efficiency of coke oven gas by vacuum potassium carbonate method

A technology of vacuum potassium carbonate and coke oven gas, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc. It can solve the problems of desulfurization efficiency drop and high concentration of lean liquid, and achieve stable acid gas composition and optimized process conditions , the effect of improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

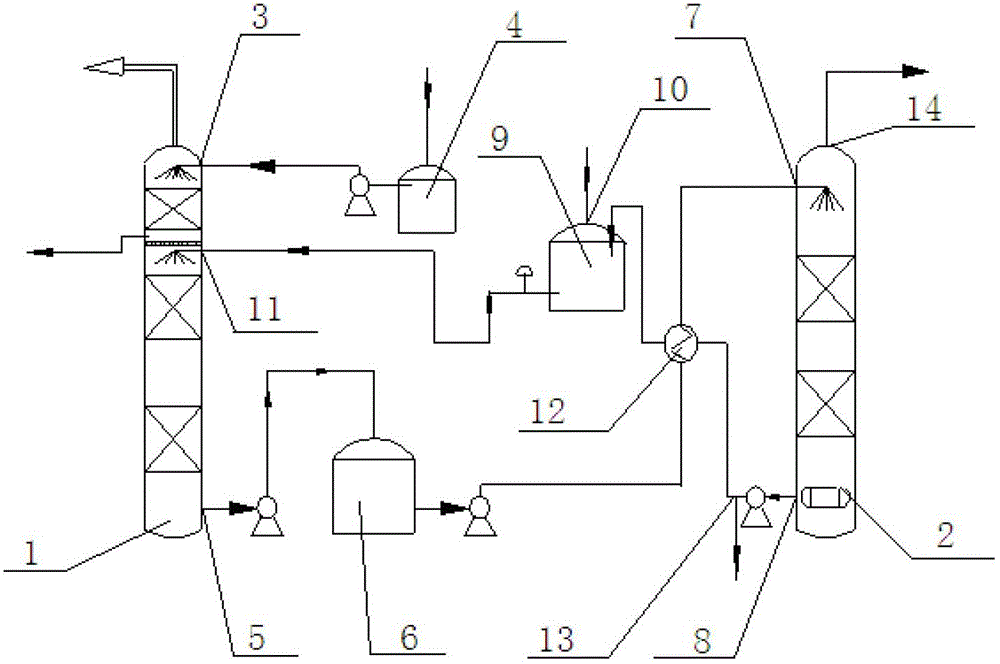

[0019] figure 1 The equipment for improving coke oven gas desulfurization efficiency by the vacuum potassium carbonate method shown in , includes a desulfurization tower 1 for absorbing acid gas in coke oven gas and a regeneration tower 2 for regenerating the desulfurization rich liquid, the upper section of the desulfurization tower 1 The washing liquid inlet 3 at the top is connected to the output end of the alkali tank 4, and the desulfurization rich liquid outlet 5 at the bottom of the lower section of the desulfurization tower 1 is connected to the input end of the rich liquid tank 6, and the output end of the rich liquid tank 6 is passed through heat exchange The heat medium pipeline of the device 12 communicates with the rich liquid inlet 7 at the top of the regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com