Preparation method of hydroxylated multi-wall carbon nanotube-polysilane composite material

A multi-wall carbon nanotube and composite material technology is applied in the field of preparation of multi-wall carbon nanotube-polysilane composite materials, can solve the problems of complex synthesis steps, difficult reaction control, low content of silicon elements, etc., and achieves simple synthesis steps , improve thermal stability and electrical conductivity, improve the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

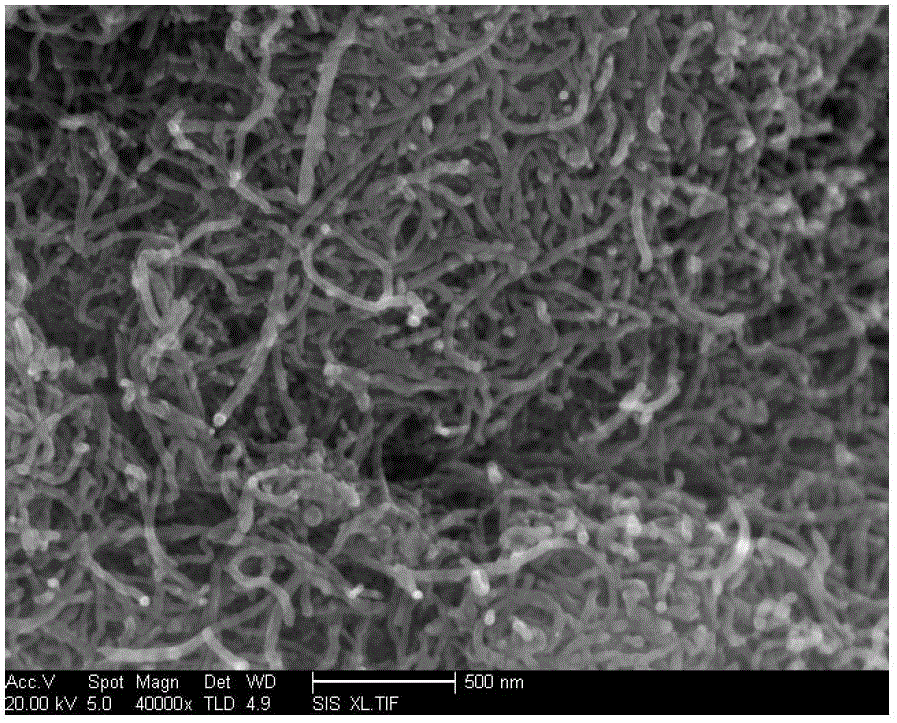

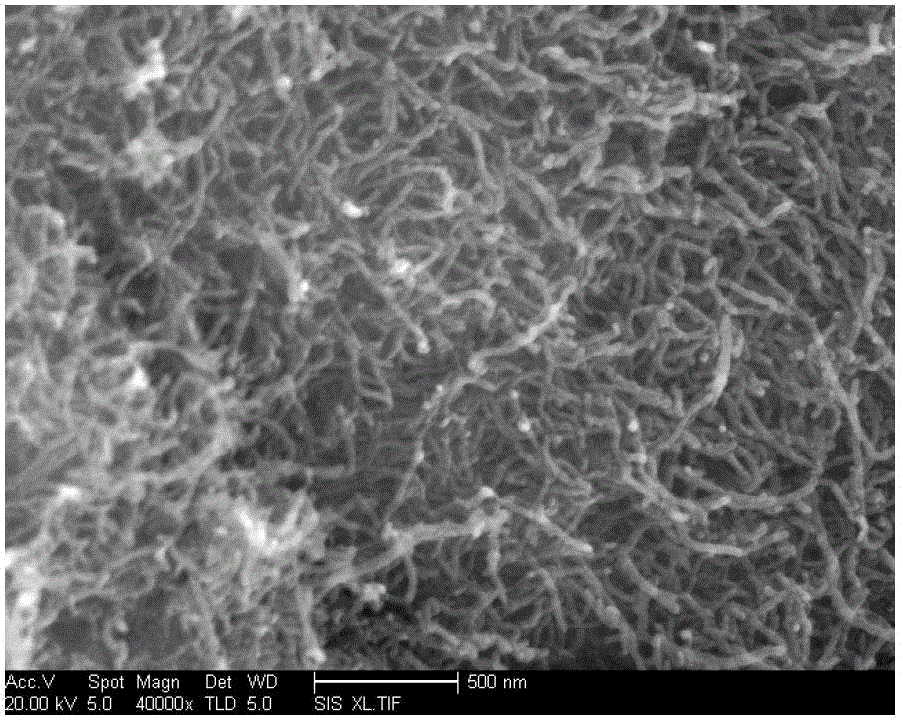

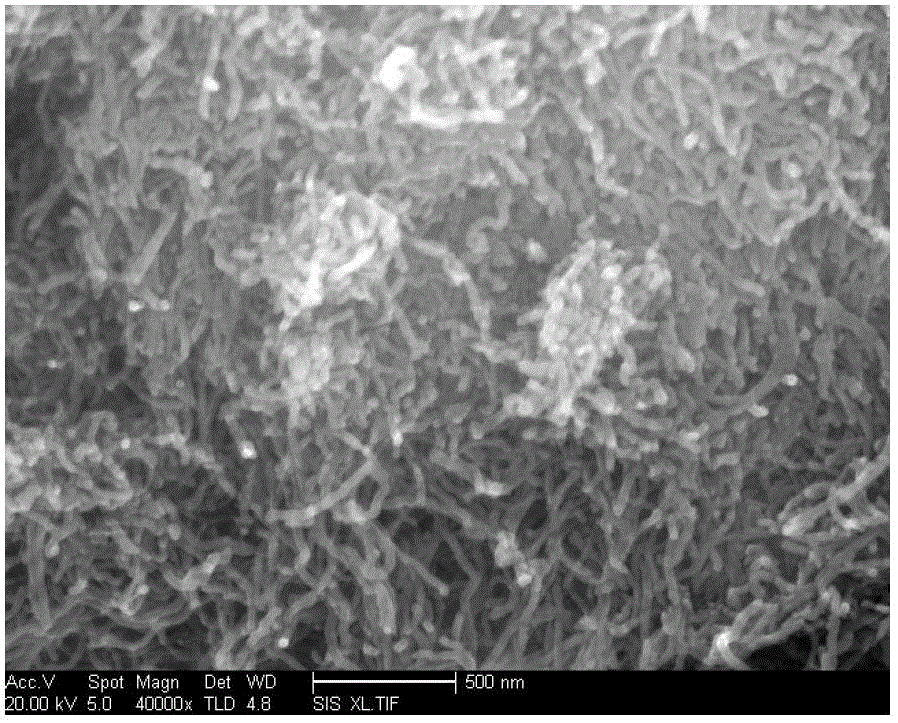

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: This embodiment is a method for preparing a hydroxylated multi-walled carbon nanotube-polysilane composite material, which is specifically completed according to the following steps:

[0024] 1. Purification: (1) Calcination: First, calcine the multi-walled carbon nanotubes at a temperature of 420°C~480°C for 20min~40min to obtain the calcined multiwalled carbon nanotubes; (2) Nitric acid purification: the calcined Pour the multi-walled carbon nanotubes into the nitric acid aqueous solution with a concentration of 3mol / L~6mol / L, and stir for 12h~24h at a temperature of 20°C~25°C and a stirring speed of 500r / min~1000r / min, and then use G4 sand core funnel is filtered, and the filter cake obtained by filtering is rinsed with distilled water until the pH of the filtrate=7±0.1, that is, the multi-walled carbon nanotubes after nitric acid purification are obtained; (3) hydrochloric acid purification: the purified nitric acid The multi-walled carbon nanotubes we...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the dichlorosilane derivatives described in step three (2) are dimethyl dichlorosilane, diethyl dichlorosilane, dipropyl Dichlorosilane, methylphenyldichlorosilane or methylvinyldichlorosilane. Others are the same as the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the organic solvent described in step four (1) is toluene, xylene, octane or cycloheptane. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com