Color-fixing polyester and preparation method thereof

A technology of polyester and color properties, applied in the field of color-fixing polyester and its preparation, can solve problems such as unstable color and achieve stable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

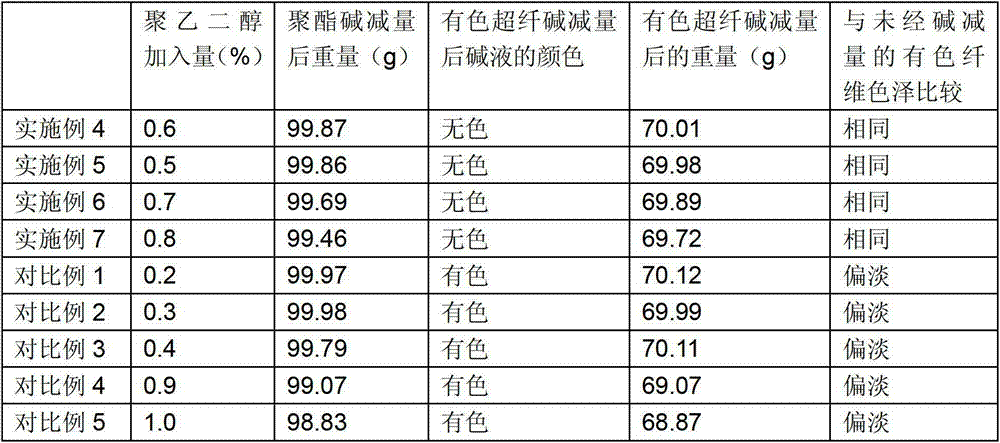

Examples

Embodiment 1

[0013] Mix purified terephthalic acid and ethylene glycol at a molar ratio of 1.2:1 for beating, add 0.025% of antimony trioxide, 0.016% of tripotassium phosphate and 0.0015% of cobalt acetate, which account for the weight of color-fixing polyester, and mix After uniformity, it is sent to the esterification tank for esterification reaction; the product of the esterification reaction is sent to the polycondensation tank, and then 0.8% of the weight of the color-fixing polyester is added. Polyethylene glycol with an average molecular weight of 4000 is mixed and polymerized reaction. In the low vacuum stage of the polymerization reaction, the temperature was controlled at 248° C. for 2 hours, and in the high vacuum stage of the polymerization reaction, the temperature was controlled at 275° C. for 3 hours. After the reaction is finished, the obtained polymer is pressed out from the kettle and granulated to obtain the obtained polymer.

[0014] The color-fixing polyester prepared...

Embodiment 2

[0016] Mix purified terephthalic acid and ethylene glycol at a molar ratio of 1.3:1 for beating, add 0.023% of antimony trioxide, 0.0165% of tripotassium phosphate and 0.0017% of cobalt acetate to the weight of color-fixing polyester, and mix After uniformity, it is sent to the esterification tank for esterification reaction; the product of the esterification reaction is sent to the polycondensation tank, and then 0.7% of the weight of the color-fixing polyester is added. Polyethylene glycol with an average molecular weight of 5000 is mixed and polymerized reaction. In the low vacuum stage of the polymerization reaction, the temperature was controlled at 249° C. for 1.5 hours, and in the high vacuum stage of the polymerization reaction, the temperature was controlled at 276° C. for 3.75 hours. After the reaction is finished, the obtained polymer is pressed out from the kettle and granulated to obtain the obtained polymer.

[0017] The color-fixing polyester prepared in this e...

Embodiment 3

[0019] Mix purified terephthalic acid and ethylene glycol at a molar ratio of 1.5:1 for beating, add 0.025% of antimony trioxide, 0.0175% of tripotassium phosphate and 0.002% of cobalt acetate, which account for the weight of color-fixing polyester, and mix After uniformity, it is sent to the esterification tank for esterification reaction; the product of the esterification reaction is sent to the polycondensation tank, and then 0.5% of the weight of the color-fixing polyester is added. Polyethylene glycol with an average molecular weight of 7000 is mixed and polymerized reaction. In the low vacuum stage of the polymerization reaction, the temperature was controlled at 250° C. for 1 hour, and in the high vacuum stage of the polymerization reaction, the temperature was controlled at 278° C. for 2 hours. After the reaction is finished, the obtained polymer is pressed out from the kettle and granulated to obtain the obtained polymer.

[0020] The color-fixing polyester prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com