Super absorbent resin with lower liquid absorbing rate, and preparation method and application thereof

A technology of super absorbent resin and liquid absorption rate, applied in the field of super absorbent resin, can solve problems such as hindering application and reducing concrete work performance, and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

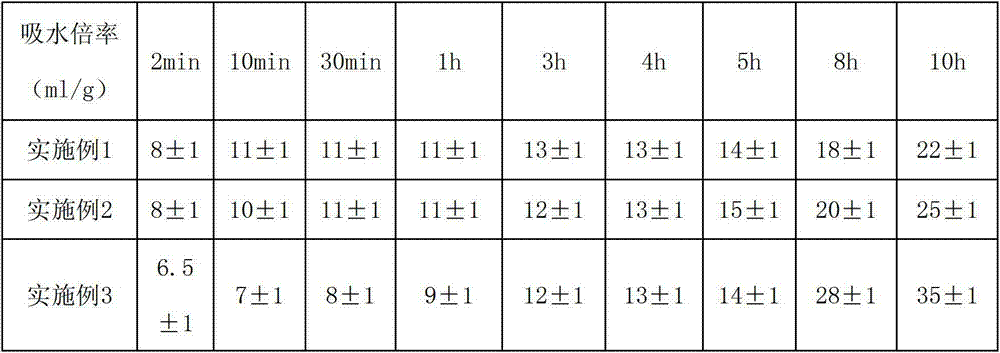

Embodiment 1

[0030] 125g of an aqueous solution containing 80% acrylic acid is neutralized with 230g of a 34% NaOH solution. This process needs to be carried out slowly so that the temperature does not exceed 30°C, and then 1.1g of potassium persulfate and 2.9g of 1,4-butanediol diacrylate are added. Stir evenly and place it at 65°C for 2 hours to react. The obtained gel is dried and pulverized to obtain irregularly shaped SAP particles.

Embodiment 2

[0032] 125g of an aqueous solution containing 80% acrylic acid is neutralized with 230g of a 34% NaOH solution. This process needs to be carried out slowly so that the temperature does not exceed 30°C, and then 1.1g of potassium persulfate and 2.9g of 1,4-butanediol diacrylate are added. The reaction solution after stirring evenly was added to 533 g of cyclohexane dissolved with 0.8% SPAN80, the stirring rate was controlled at 200 rpm / min, and the reaction solution was placed at 65°C for 2 hours, filtered and dried to obtain spherical SAP particles.

Embodiment 3

[0034] 62.5g aqueous solution containing 80% acrylic acid is neutralized with 115g 34% NaOH solution, the process needs to be carried out slowly so that the temperature does not exceed 30°C, then add 0.55g potassium persulfate, 0.58g 1,4-butanediol diacrylate , Stir the reaction liquid a evenly, add 533g of cyclohexane dissolved with 0.8% SPAN80 (Span-80), control the stirring rate at 200rpm / min, and place it at 65°C for reaction;

[0035] When the previous steps take place, neutralize 62.5g of an aqueous solution containing 80% acrylic acid with 115g of a 34% NaOH solution, the process needs to be carried out slowly so that the temperature does not exceed 30°C, then add 0.55g of potassium persulfate, 2.32g1, 4-butanediol diacrylate, the reaction liquid b after stirring evenly.

[0036] The reaction solution b was slowly dropped into the reaction solution a which had been reacted for 1 hour, and then reacted at 65° C. for another 2 hours after the dropwise addition, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com