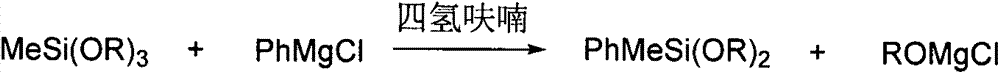

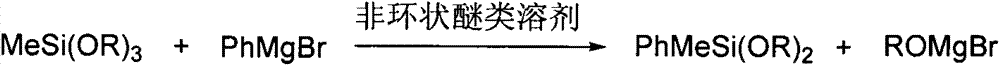

Method for synthesizing phenyl methyl dialkoxyl silane with high selectivity

A technology of phenylmethyldialkoxysilane and methyltrialkoxysilane, which is applied in the field of organosilicon chemical industry, can solve problems affecting heat and mass transfer, side reactions, and high reaction temperature, so as to improve selectivity and yield, make up for costs, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 (this embodiment is not included in the scope of the present invention as a comparative example. In a 5L four-necked flask, add 241g methyltrimethoxysilane and 1000mL tetrahydrofuran. Start stirring, add dropwise 1030mL concentration of 1.72mol / L The solution of chlorophenyl Grignard reagent in tetrahydrofuran.After reacting for 1 hour, most of tetrahydrofuran was evaporated by heating.Add 1000mL dimethylbenzene, continue to distill remaining tetrahydrofuran.Filter after being down to room temperature, filtrate obtains 99g phenylmethyl dihydrofuran through fractional distillation Methoxysilane (31% yield) and 69 g of diphenylmethylmethoxysilane (17% yield).

Embodiment 2

[0050] Add 377g of methyltriethoxysilane and 1000mL of ether into a 5L four-neck flask, and add dropwise 1080mL of bromophenyl Grignard reagent ether solution with a concentration of 1.63mol / L under stirring; Filtration; the filtrate is fractionated, reclaimed ether and excess methyltriethoxysilane, then distilled under reduced pressure to obtain phenylmethyldiethoxysilane 316g (yield 86%) and diphenylmethylethoxysilane 11 g (yield 3%) of silane.

Embodiment 3

[0052] Add 240g of methyltrimethoxysilane and 1000mL of ether into a 5L four-neck flask, and add dropwise 1080mL of bromophenyl Grignard reagent ether solution with a concentration of 1.63mol / L under stirring; 1000 mL of n-hexane was added to the system, and then filtered; the filtrate was fractionated to obtain 305 g of phenylmethyldimethoxysilane (yield 95%) and 4 g of diphenylmethylmethoxysilane (yield 1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com