Bag tearing ventilation and dust removing equipment and method

A kind of dust removal equipment and equipment technology, applied in the direction of separation methods, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems that affect the physical and mental health of workers in the working environment, low degree of automation, and incomplete dust removal, etc., so as to avoid harm to the staff. Hazards, high degree of automation, effect of protecting the environment and working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

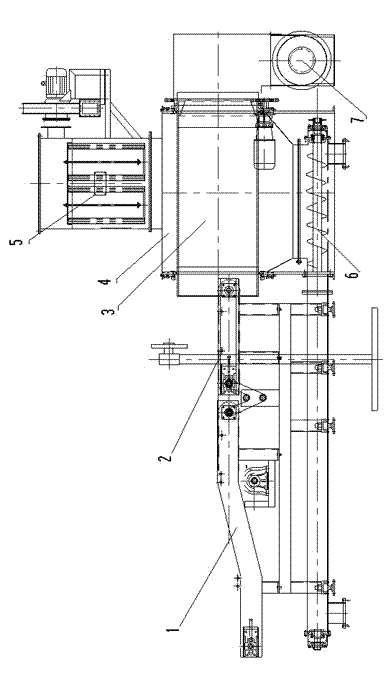

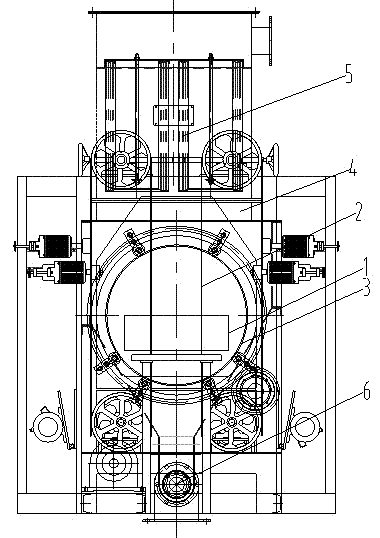

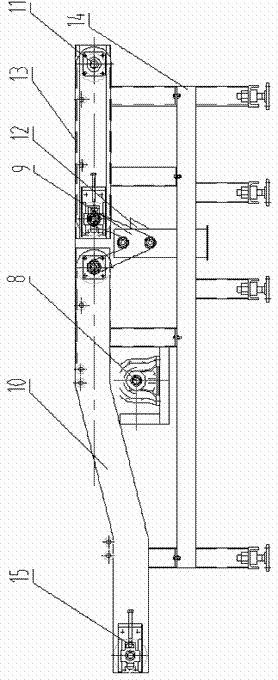

[0030] Refer to attached Figure 1-10 , to further describe the present invention:

[0031] Overall structure of the present invention is as figure 1 , figure 2 As shown, it is composed of a belt conveyor 1, a cutter device 2, a drum screen 3, an intermediate support 4, a filter element ventilation dust collector 5, a screw conveying device 6, a waste bag automatic recovery device 7, and a control box. The belt conveyor 1 is located on one side of the equipment, the upper end of the middle bracket 4 is a filter-type ventilation and dust collector, the lower end is a drum screen 3, and the lower end of the drum screen 3 is a screw conveying device 6, and the cutter device 2 is located on the side of the feeding port, at the front end of the drum screen 3, The waste bag automatic recovery device is located at the rear side of the trommel 3, and the control box is arranged outside the equipment.

[0032] Belt conveyor 1 main components such as image 3 Including: conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com