Process and device for forming micro-bulge oil film on surface of workpiece under nano particle jet flow condition

A nanoparticle and workpiece surface technology, which is used in grinding/polishing safety devices, manufacturing tools, metal processing equipment, etc. The internal relationship between the surface morphology of the lubricating oil film and the formation mechanism of the nano-particle oil film have not been established to achieve the effects of good heat transfer performance, enhanced heat transfer performance, and reduced friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the present invention is described:

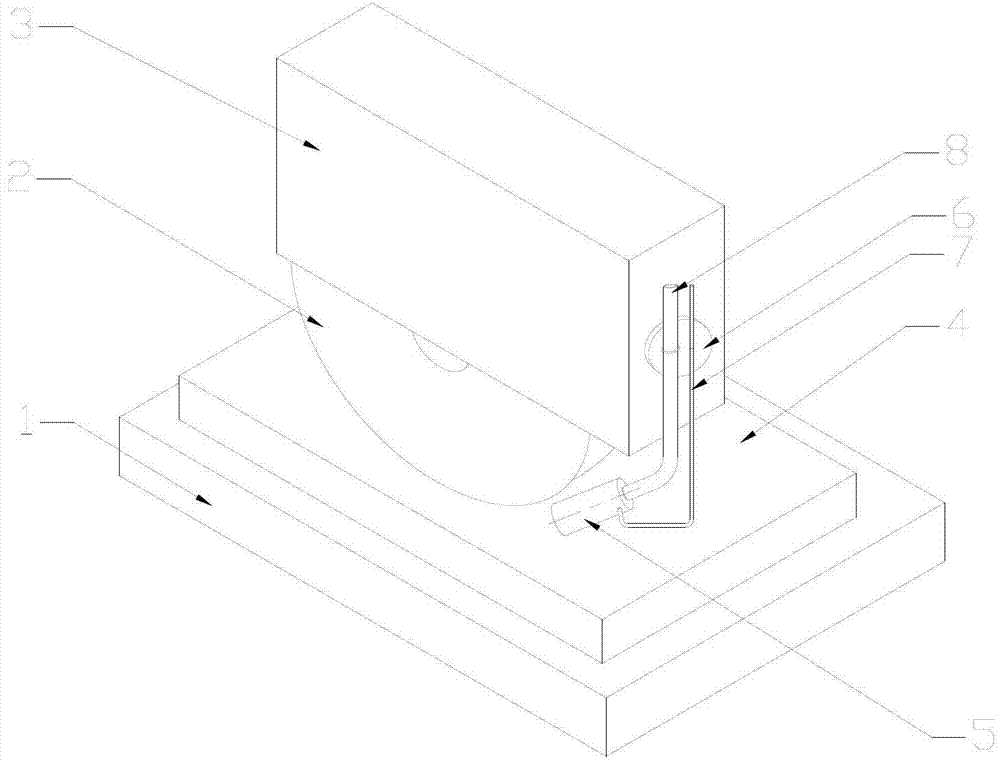

[0045] like figure 1 As shown, the workpiece 4 is installed on a part of the workbench 1, the magnetic fixed suction cup 6 is adsorbed on the side of the grinding wheel cover 3, and the compressed air delivery pipe 7 and the nanofluid delivery pipe 8 are fixed by the magnetic fixed suction cup 6. One end of the nanofluid delivery pipe 8 is connected to the nanofluid inlet of the nozzle 5, and the other end is connected to the turbine flowmeter II22. One end of the compressed gas delivery pipe 7 is connected to the compressed gas inlet of the nozzle 5, and the other end is connected to the turbine flowmeter I21.

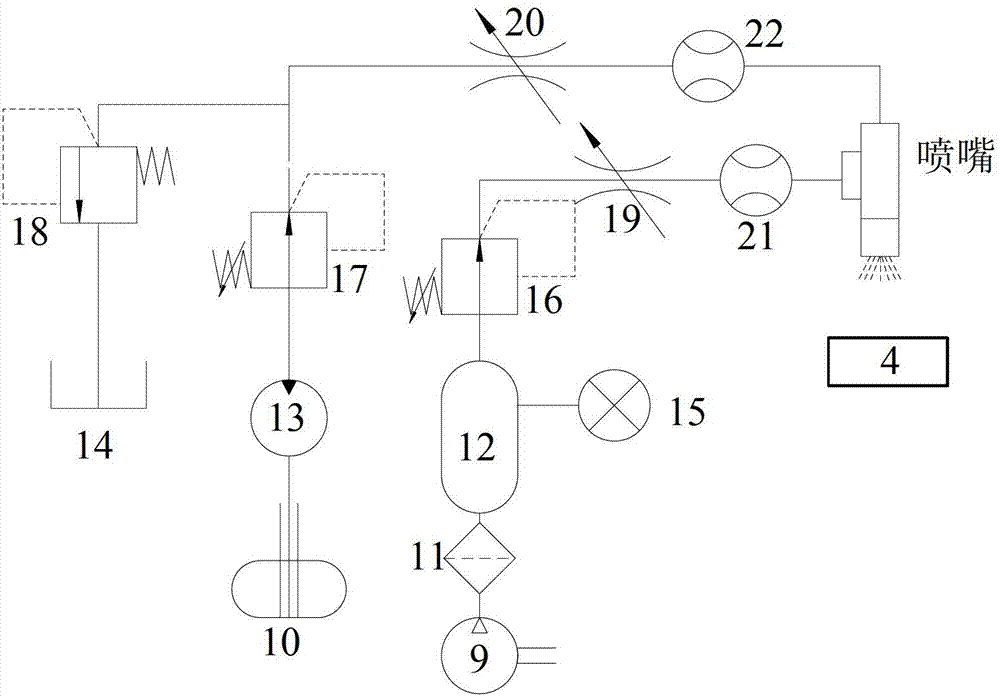

[0046] like figure 2 As shown, the air circuit is composed of an air compressor 9, a filter 11, an air storage tank 12, a pressure regulating valve I16, a throttle valve I19, and a turbine flowmeter I21. Nanofluid storage tank 10, hydraulic pump 13, pressure regulating val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com