Manufacturing method of precision casting of titanium alloy impeller

A manufacturing method and technology of precision castings, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as unsatisfactory design performance, undetectable inner cavity of blade mold, difficult core processing, etc., and achieve good industrial application value and market prospects, eliminating the effects of low precision and substandard performance, and facilitating CNC machining and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

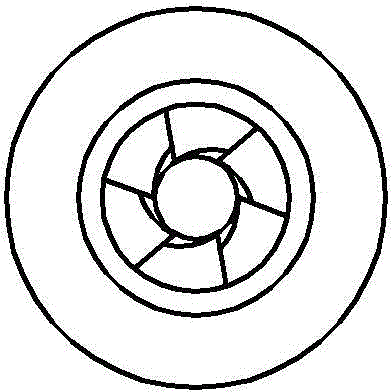

[0040]A ZTA2 titanium alloy impeller, model: 2-104 049 402, impeller dimensions ¢186×70, left-handed blade, Z=7, casting weight 4.5kg. Main manufacturing technical parameters: left-handed blade, Z=7, blade spacing at the inlet end, a1c=14+0.7 0mm (¢90), a1i=10+0.7 0mm (¢42).

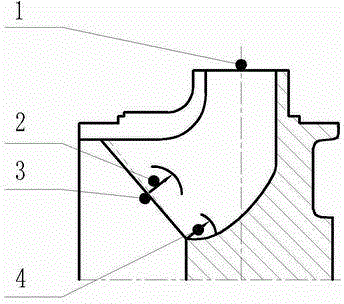

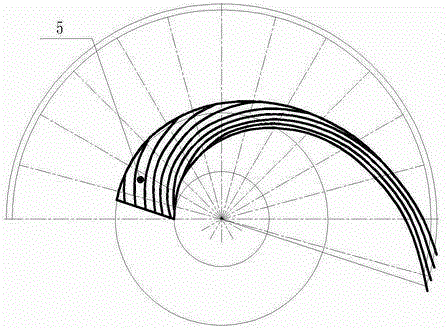

[0041] Implementation process flow: Process design of "leaf-forming method" - "leaf-forming method" graphite mold making - graphite mold brushing - graphite mold inspection - graphite mold degassing - graphite mold assembly - pouring castings - casting inspection, The specific process is:

[0042] (1), > process design scheme:

[0043] (1.1) Draw the casting drawing: According to the impeller product drawing provided by the customer, place a 3mm processing amount on the processing part, the main manufacturing technical parameters: the blade is left-handed, Z=7, the blade spacing at the inlet end, a1c=14+0.7 0mm (¢90 ), a1i=10+0.7 0mm (¢42), and the remaining dimensional tolerances are marked with casti...

Embodiment 2

[0058] A SB367-G5 titanium alloy impeller, model XY280-40-03, impeller dimensions ¢324×160, left-handed blade, Z=6, casting weight 17kg. Manufacturing technical parameters: left-handed blades, Z=6, blade spacing at the inlet end, a1c=17±0.7mm (¢125), a1i=14±0.5mm (¢76), hydraulic dimensions of castings are implemented according to GB / T6979-93B level , The impeller is tested for dynamic balance, and the unbalance is less than 6g.

[0059] Implementation process flow: Process design of "leaf-forming method" - "leaf-forming method" graphite mold making - graphite mold brushing - graphite mold inspection - graphite mold degassing - graphite mold assembly - pouring castings - casting inspection, The specific process is:

[0060] (1), > process design scheme:

[0061] (1.1) Draw the casting drawing: according to the impeller product drawing provided by the customer, put the processing amount on the processing part, the main manufacturing technical parameters: the blade is left-han...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com