Purple perilla beverage and preparation method thereof

A technology of beverage and perilla, applied in food preparation, application, food science, etc., can solve the problems of low extraction rate of nutritional active ingredients, and achieve the effect of shortening extraction time, high extraction rate, and clear color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

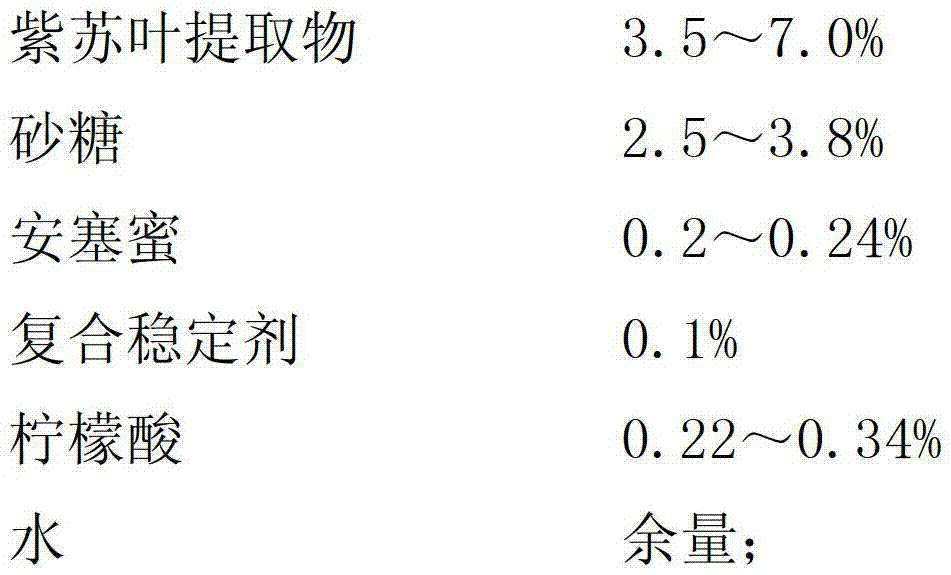

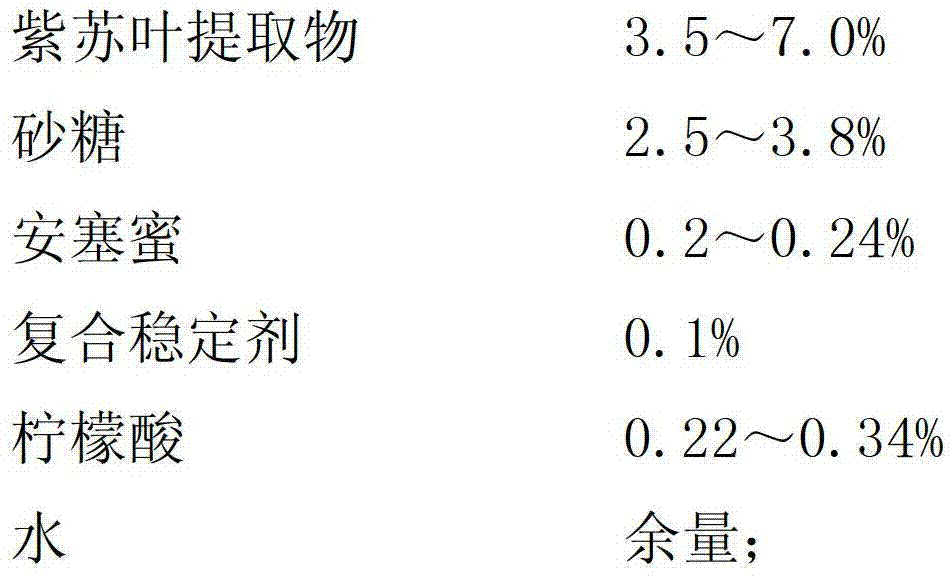

Embodiment 1

[0037] Weigh 50.0g of perilla leaf powder and disperse evenly in 200.0g of extraction solvent under stirring, heat the mixture to a constant temperature of 50°C, and ultrasonically extract at 28KHz for 45min; stop ultrasonication, filter, and reserve the filtrate; g extraction solvent, ultrasonically extract at 28KHz for 45min, stop ultrasonication, filter, mix the filtrate obtained after two times of ultrasonication according to the mass ratio of 1:1, and filter after standing for 30min to obtain 415.2g of mixed filtrate, which is vacuum-dried at 45°C to obtain Perilla leaf extract 36.4g; 36.4g perilla leaf extract, 23.3g granulated sugar, 1.6g acesulfame potassium, 0.47g sodium carboxymethylcellulose, 0.23g sodium alginate, 2.0g citric acid, 663.9g water Stir and mix evenly; filter the mixed liquid, fill the filtrate, instantaneous high temperature sterilization, light inspection, and box packing.

Embodiment 2

[0039] Weigh 50.0g of perilla leaf powder and disperse evenly in 200.0g of extraction solvent under stirring, heat the mixture to a constant temperature of 50°C, and ultrasonically extract at 28KHz for 45min; stop ultrasonication, filter, and reserve the filtrate; g extraction solvent, ultrasonically extract at 28KHz for 45min, stop ultrasonication, filter, mix the filtrate obtained after two times of ultrasonication according to the mass ratio of 1:1, and filter after standing for 30min to obtain 413.4g of mixed filtrate, which is vacuum-dried at 40°C to obtain Perilla leaf extract 32.6g; Stir and mix 32.6g perilla leaf extract, 15.8g granulated sugar, 1.3g acesulfame potassium, 0.5g sodium alginate, 1.4g citric acid, 491.8g water; filter the mixture, Filtrate filling, instantaneous high temperature sterilization, light inspection, packing.

Embodiment 3

[0041] Weigh 50.0g of perilla leaf powder and evenly disperse in 400.0g of extraction solvent under stirring, heat the mixture to a constant temperature of 50°C, and ultrasonically extract at 28KHz for 45min; stop ultrasonication, filter, and reserve the filtrate; g extraction solvent, ultrasonically extract at 28KHz for 45min, stop ultrasonication, filter, mix the filtrate obtained after two times of ultrasonication according to the mass ratio of 1:1, and filter after standing for 30min to obtain 414.3g of mixed filtrate, which is vacuum-dried at 40°C to obtain Perilla leaf extract 34.1g; stir 34.1g perilla leaf extract, 25g granulated sugar, 1.7g acesulfame potassium, 0.53g sodium carboxymethyl cellulose, 0.27g sodium alginate, 2.3g citric acid, 694.0g water Mix evenly; filter the mixed solution, fill the filtrate, instantaneously sterilize it at high temperature, inspect it with light, and pack it into boxes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com