Coriander root leisure food processing method

A technology of snack food and processing method, applied in food preparation, food science, application and other directions, can solve the problems of poor storability, high cost, difficult long-term preservation of fresh products, etc., and achieve the effect of convenient eating and good portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The processing method of embodiment 1, genus coriander root leisure food, carries out the following steps successively:

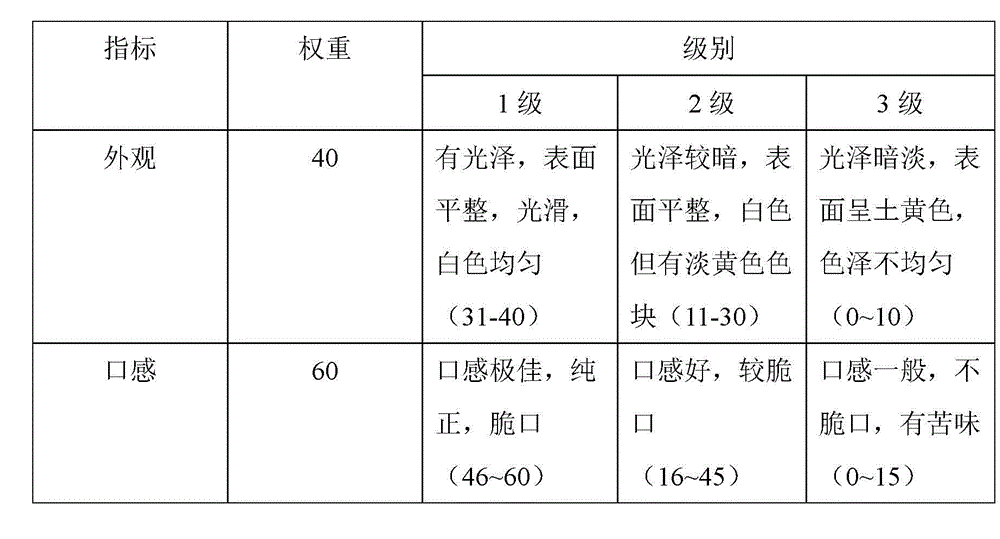

[0040] Select 5 kg of fresh coriander root tubers without rot and damage from diseases and insect pests, put them into a pool, wash them with clean water, and peel them by hand. The peeled coriander root tubers were cut into 5 mm thick slices with a SY-QP300 slicer, and then blanched in hot water at 95 °C for 0.5 minutes. After blanching, the coriander root slices are put into the dipping tank, soaked with 35% sucrose aqueous solution at room temperature (10-35°C) for 0.5 hours to obtain the soaked coriander root slices. Drain the impregnated coriander root slices and place them in a vacuum freezer for drying (setting temperature -30°C ~ -28°C, pressure 100 Pa, heating plate temperature 60-65°C, material load 5 kg, The drying time was 20 h). After the drying, nitrogen was filled to break the vacuum, and the package was weighed and packaged in time t...

Embodiment 2

[0041] Embodiment 2, select 5 kg of fresh coriander root tubers without rot and damage by diseases and insect pests, put them into a pool, wash them with clear water, and peel them by hand. Cut the peeled coriander root tubers into 10 mm thick slices with a SY-QP300 slicer and put them in hot water at 95°C for 0.5 minutes to blanch. After blanching, the coriander root slices are put into the dipping tank, and soaked with 15% fructose aqueous solution at room temperature (10-35°C) for 1.5 hours to obtain the soaked coriander root slices. After dipping, drain and put the coriander root slices into a plate and put them into a freezer at -30 °C for 5 hours; then carry out microwave vacuum freeze-drying on the pre-frozen coriander root slices (95 Pa, microwave power 7 W / g, material The loading capacity was 5 kg, and the drying time was 2 hours). After drying, nitrogen was filled to break the vacuum, and the packaging was weighed in time to obtain 0.58 kg of coriander root chips. M...

Embodiment 3

[0042]Example 3. Select 5 kg of fresh coriander root tubers without rot and damage by diseases and insect pests, put them in a pool, wash them with clear water, and peel them by hand. Cut the peeled coriander root tubers into strips with a thickness of 6 mm, a length of 30 mm, and a width of 8 mm with a QTJ-200 strip cutter, and then blanched them in hot water at 80 °C for 3 minutes. After blanching, put coriander root strips into the dipping tank, and soak for 1.0 hour with 25% lactose aqueous solution at room temperature (10-35°C) to obtain soaked coriander root strips. Drain the dipped coriander root strips and place them in a vacuum freezer for drying (setting temperature -30°C ~ -28°C, pressure 85 Pa, heating plate temperature 60-65°C, material load 5 kg, The drying time was 25 h). After drying, nitrogen was filled to break the vacuum, and the package was weighed and packaged in time to obtain 0.61 kg coriander root strips. The moisture content of coriander root strips i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com