Dicing / die bonding integral film, dicing / die bonding integral film manufacturing method, and semiconductor chip manufacturing method

一种芯片焊接、半导体的技术,应用在半导体/固态器件制造、半导体器件、薄膜/薄片状的粘合剂等方向,能够解决半导体芯片控制膜厚困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

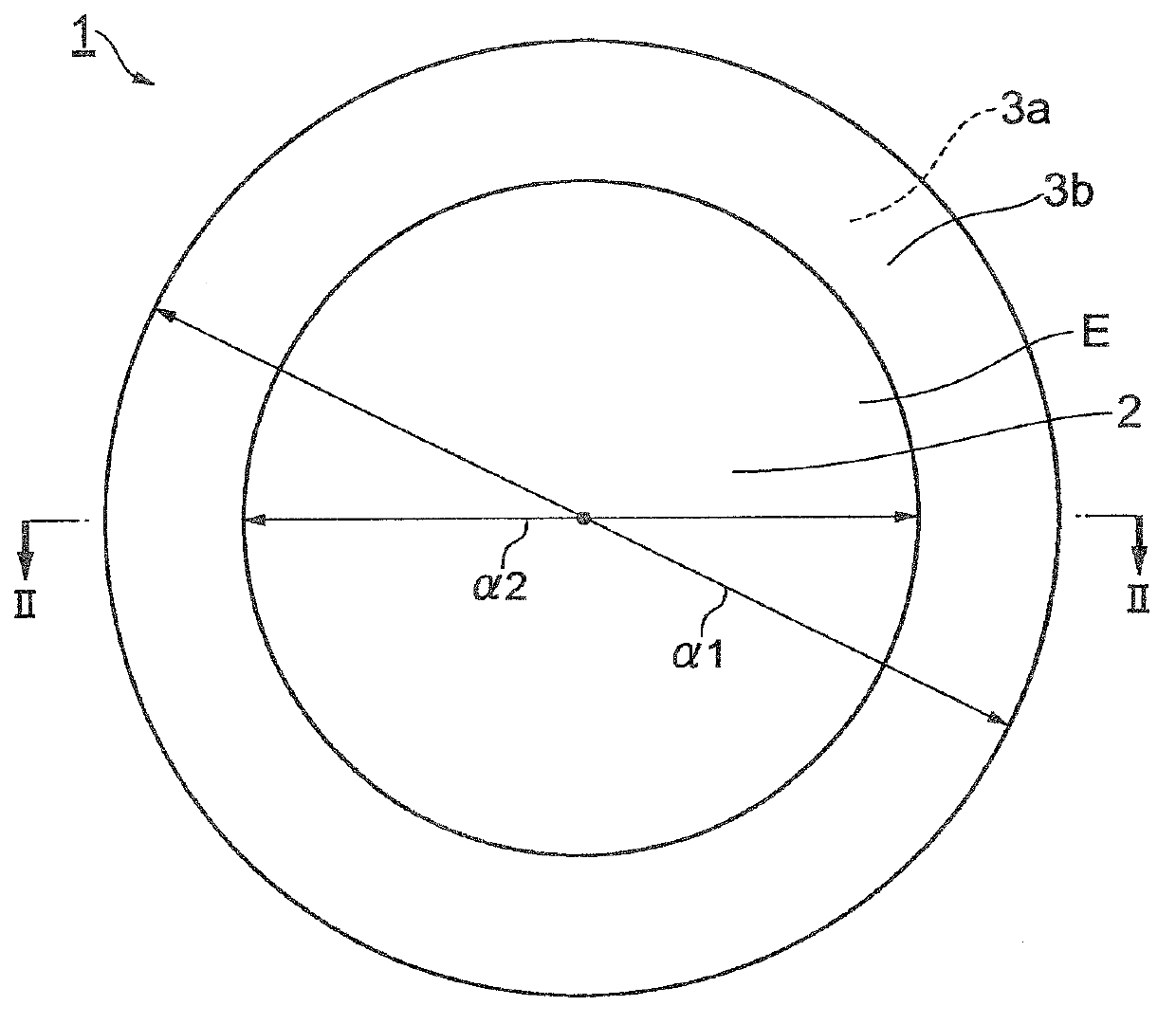

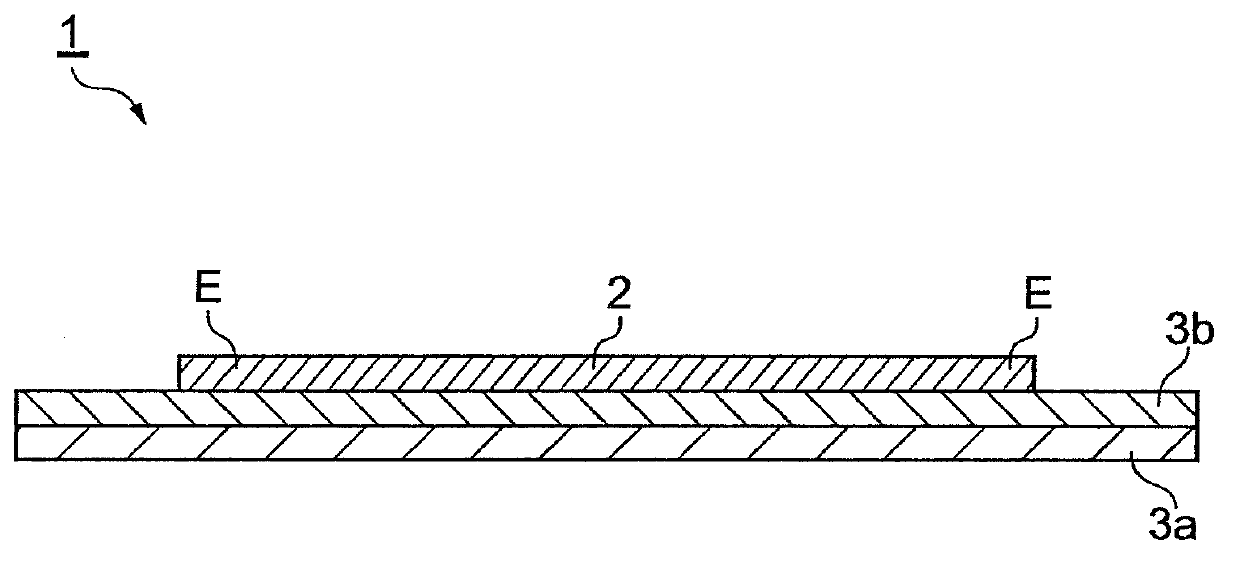

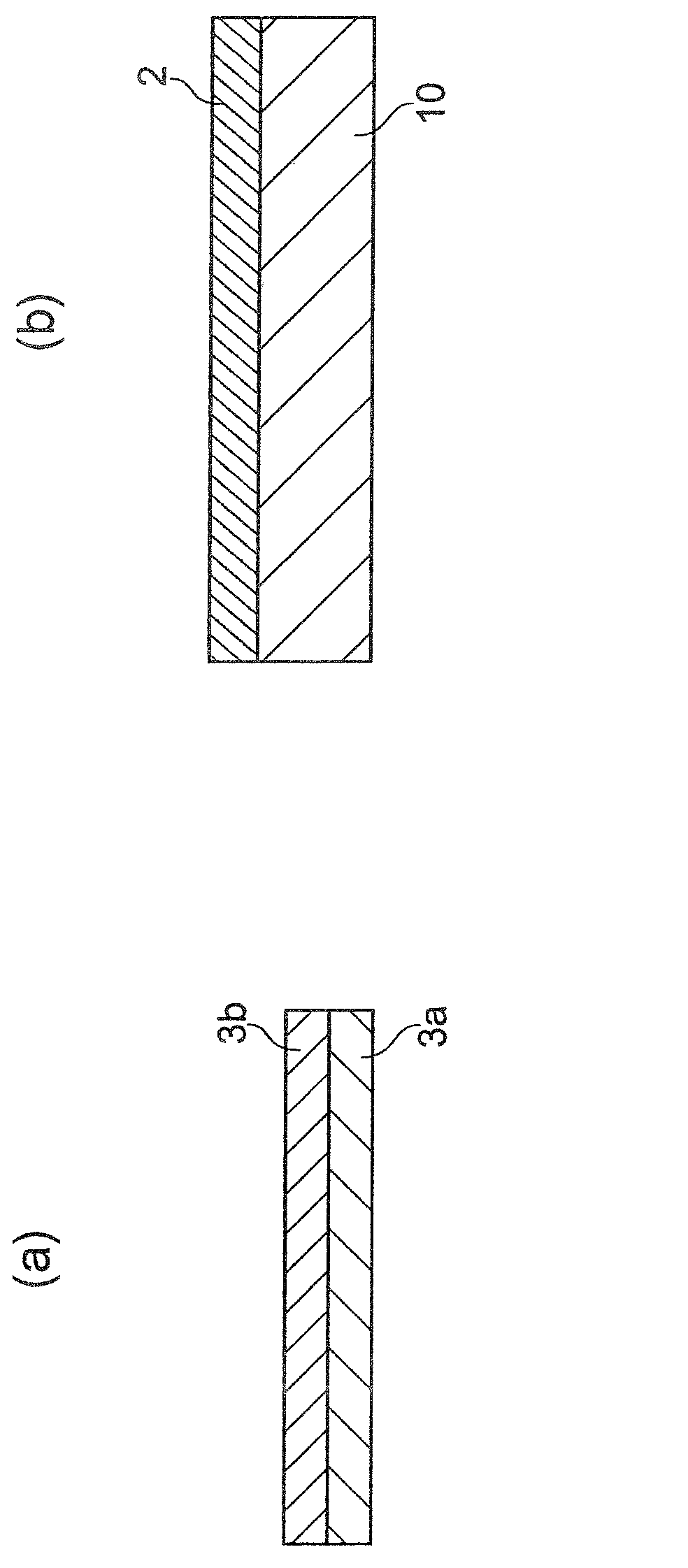

[0063] In Example 1, an example using a silicon wafer having a thickness of 75 μm and a diameter of 203 mm (8 inches) and a wafer ring having a diameter of 248 mm or more was shown. First, a 300-mm-wide dicing film (for example, SD-3001 Series manufactured by Hitachi Chemical Industries, Ltd.) in which an adhesive layer was formed on a base film was prepared. In addition, a die-bonding film (for example, FH-900 Series manufactured by Hitachi Chemical Industries, Ltd.) in which an adhesive layer was formed on a peelable base material was prepared.

[0064] Next, the adhesive layer was pre-cut (pre-cut) so that the planar shape of the adhesive layer of the die-bonding film was a circle with a diameter of 223 mm. At this time, the adhesive layer is pre-diced so that the area of the adhesive layer is larger than the area of the silicon wafer to be diced and smaller than the area of the adhesive layer and the base film.

[0065] Next, the surface on which the adhesive layer ...

Embodiment 2~8

[0068] In Examples 2-8, the diameters of the adhesive bond layer of the die-bonding film were 225 mm, 228 mm, 230 mm, 233 mm, 235 mm, 238 mm, and 240 mm, respectively, and the conditions were the same as in Example 1.

Embodiment 9~16

[0072] In Example 9, a silicon wafer with a thickness of 75 μm and a diameter of 305 mm (12 inches), a wafer ring with a diameter of 350 mm or more, and a dicing film with a width of 400 mm were used, and the diameters of the adhesive layer of the die-bonding film were 325 mm, 327 mm, and 330 mm, respectively. , 332mm, 335mm, 337mm, 340mm, 342mm, except that, it is the same condition as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com