Shielding case and preparation method thereof

A technology of shielding cover and supporting layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare aluminum foil, polycarbonate plastic composite shield:

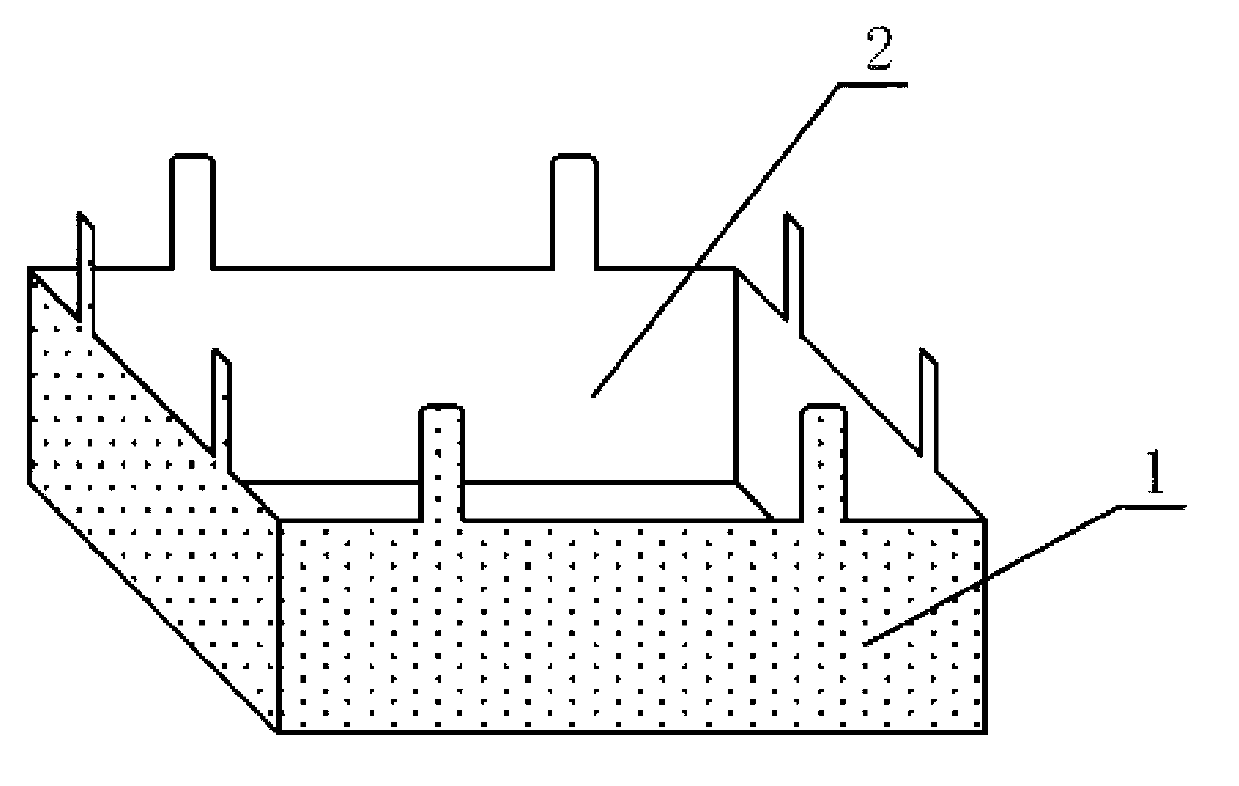

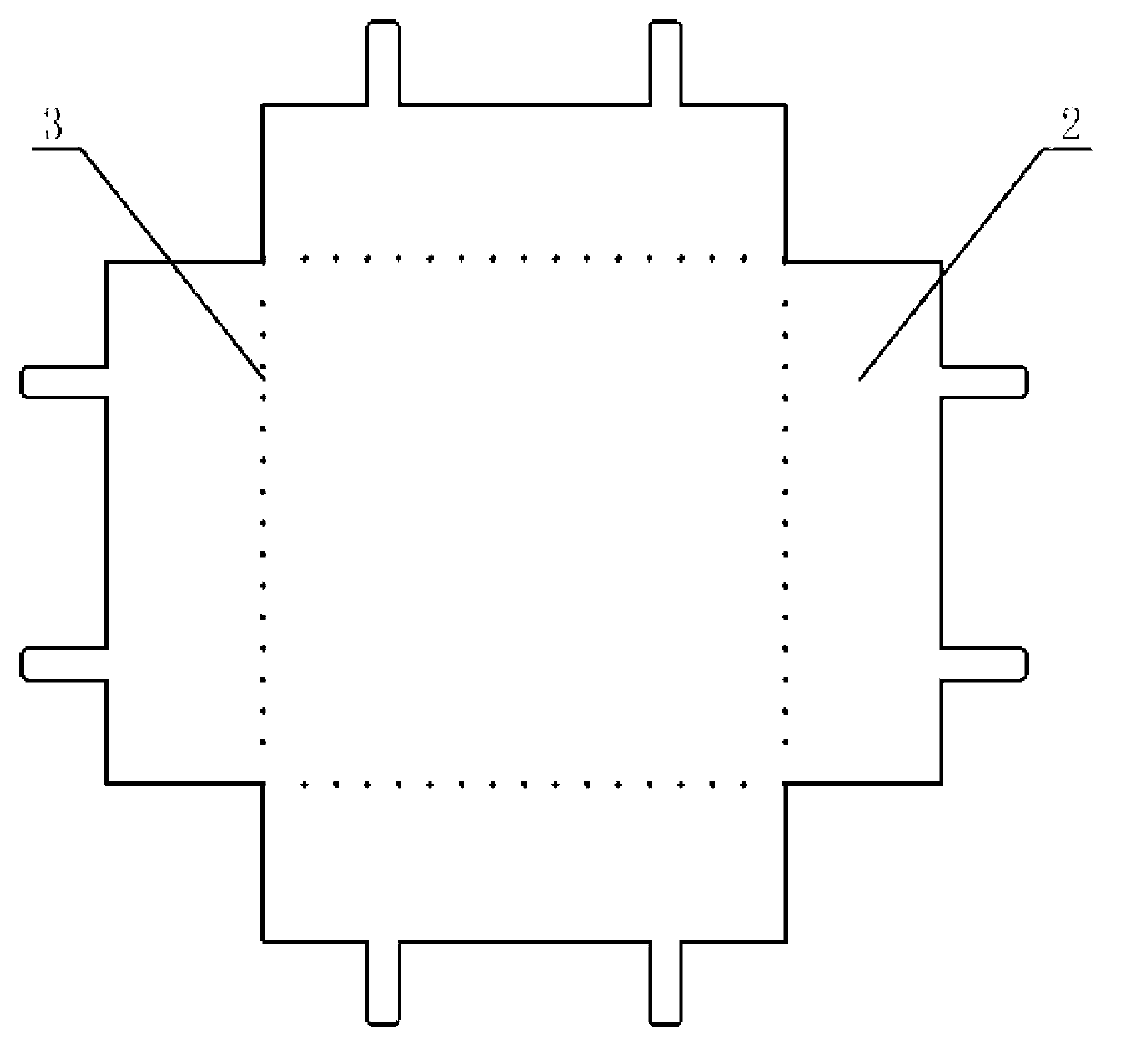

[0031] The aluminum foil-polycarbonate layered composite material was prepared by compounding the aluminum foil single-sided adhesive tape with a thickness of 0.05mm and the rolled polycarbonate plastic with a thickness of 0.43mm. Then die-cut the composite layered composite material, cut the plastic surface, and obtain the shielding cover mold material with the same shape as the overall shape after the shielding cover is unfolded (as shown in the attached figure 2 ). At the same time, in accordance with the folding requirements for preparing the shielding cover, use the indentation line of the knife die to press out the crease line 3 on the surface of the polycarbonate layer at the part of the shielding cover mold material that needs to be folded, and then drain the edge waste of the product. Finally, use a plastic bending machine to bend the shielding cover mold material obtained above according to the ...

Embodiment 2

[0034] Preparation of copper foil-polyester plastic composite shield:

[0035] The copper foil single-sided tape with a thickness of 0.05mm is compounded with a roll-shaped polyester plastic with a thickness of 0.188mm to prepare an aluminum foil-polyester layered composite material. Then carry out die-cutting processing on the compounded layered composite material, cut the plastic surface, and obtain the shielding cover molding material whose shape is consistent with the overall shape of the shielding cover after unfolding. At the same time, according to the folding requirements for the preparation of the shielding cover, use the indentation line of the knife mold to press the crease line on the surface of the polyester layer at the part of the shielding cover mold material that needs to be folded, and then discharge the edge waste of the product. Finally, a plastic bending machine is used to bend the shielding cover mold material obtained above according to the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com