Power connector

A technology for power connectors and docking parts, applied in base/housing, cooling/ventilation/heating transformation, etc., can solve interference (such as static interference, electromagnetic wave interference, impedance matching, affecting the performance and safety of the whole system, hot air It is not easy to solve problems such as increasing heat dissipation, improving safety, and increasing current flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical means and structure adopted by the present invention are described in detail with reference to the preferred embodiments of the present invention, and its features and functions are as follows in order to facilitate a complete understanding.

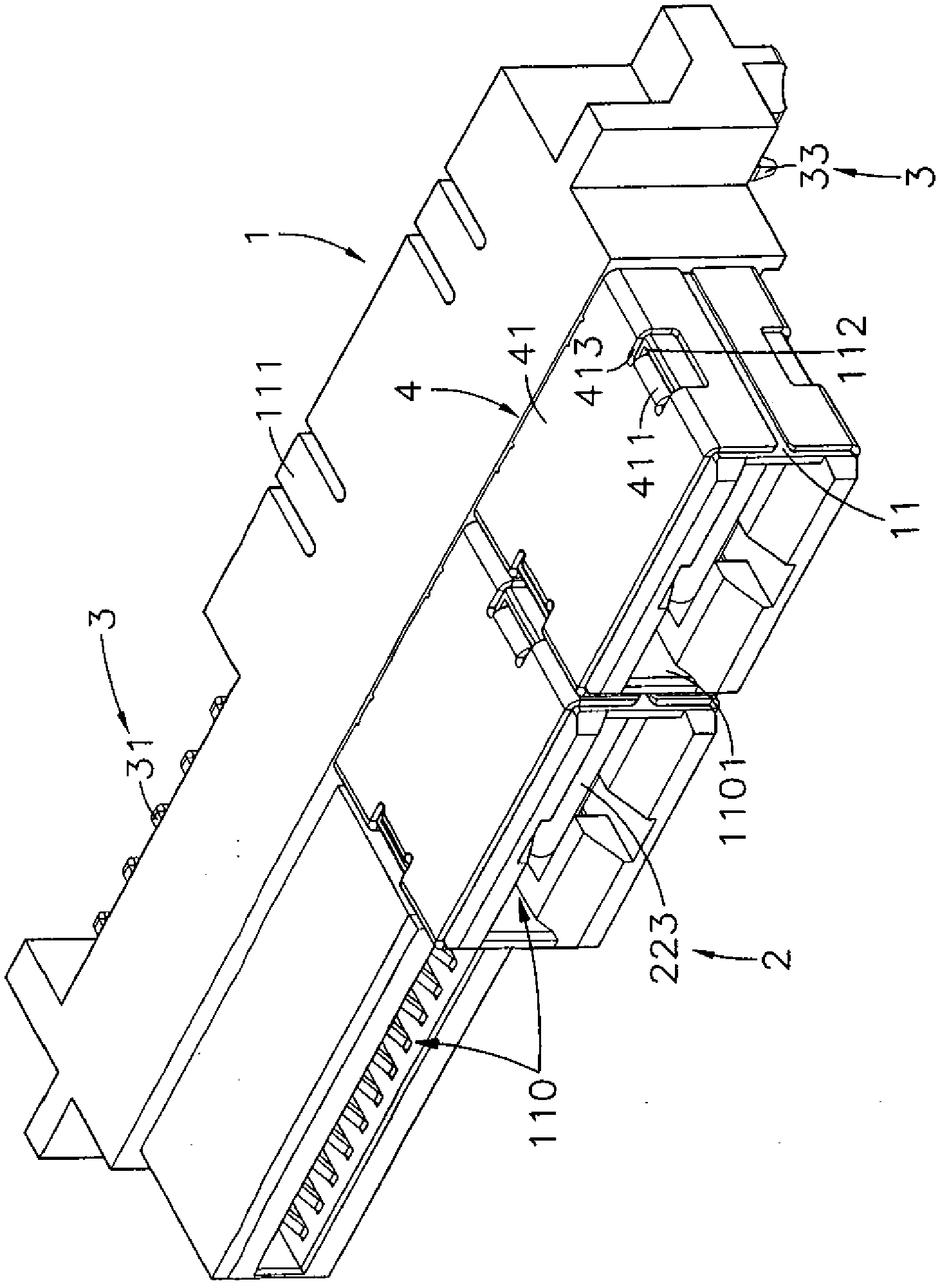

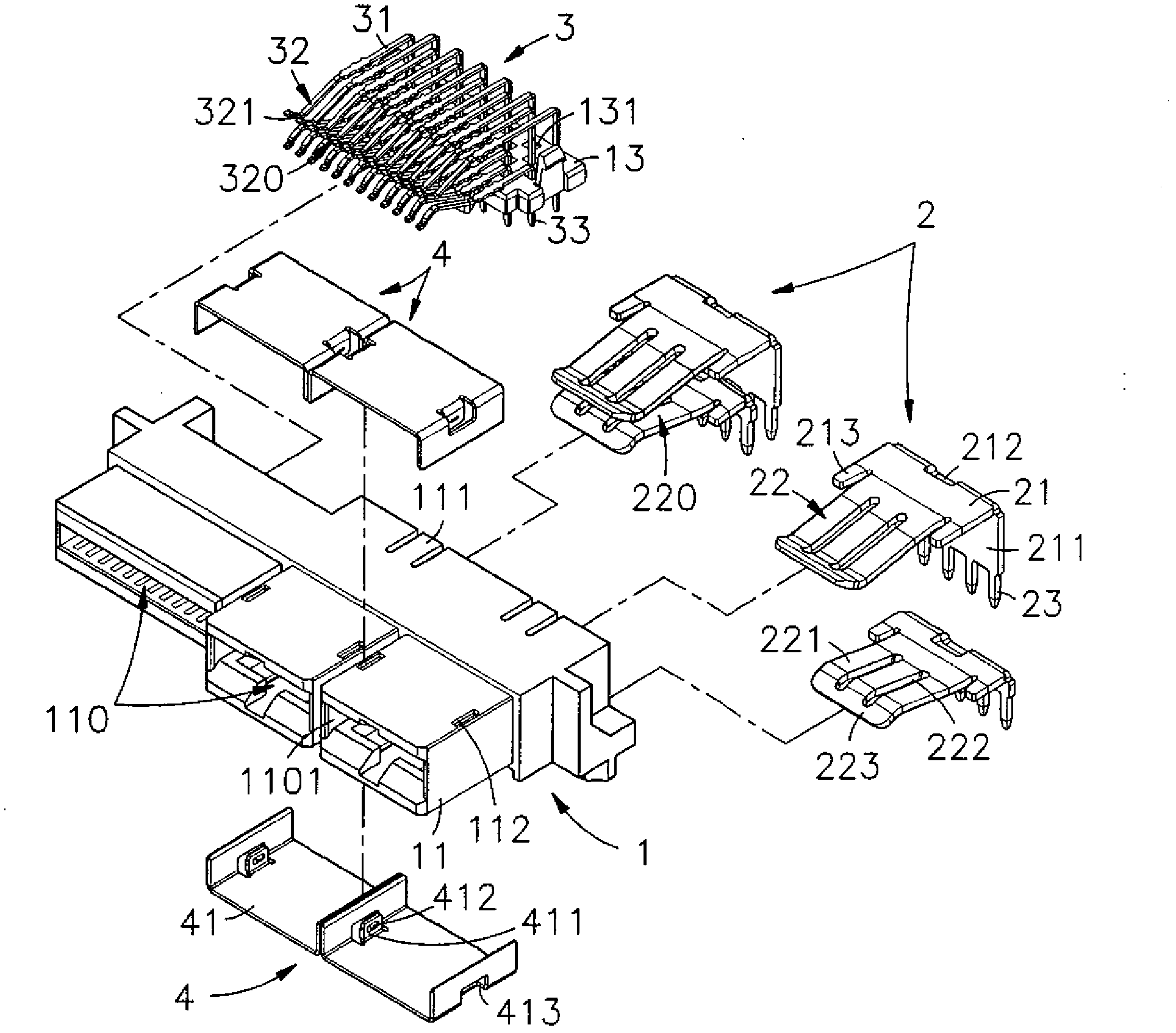

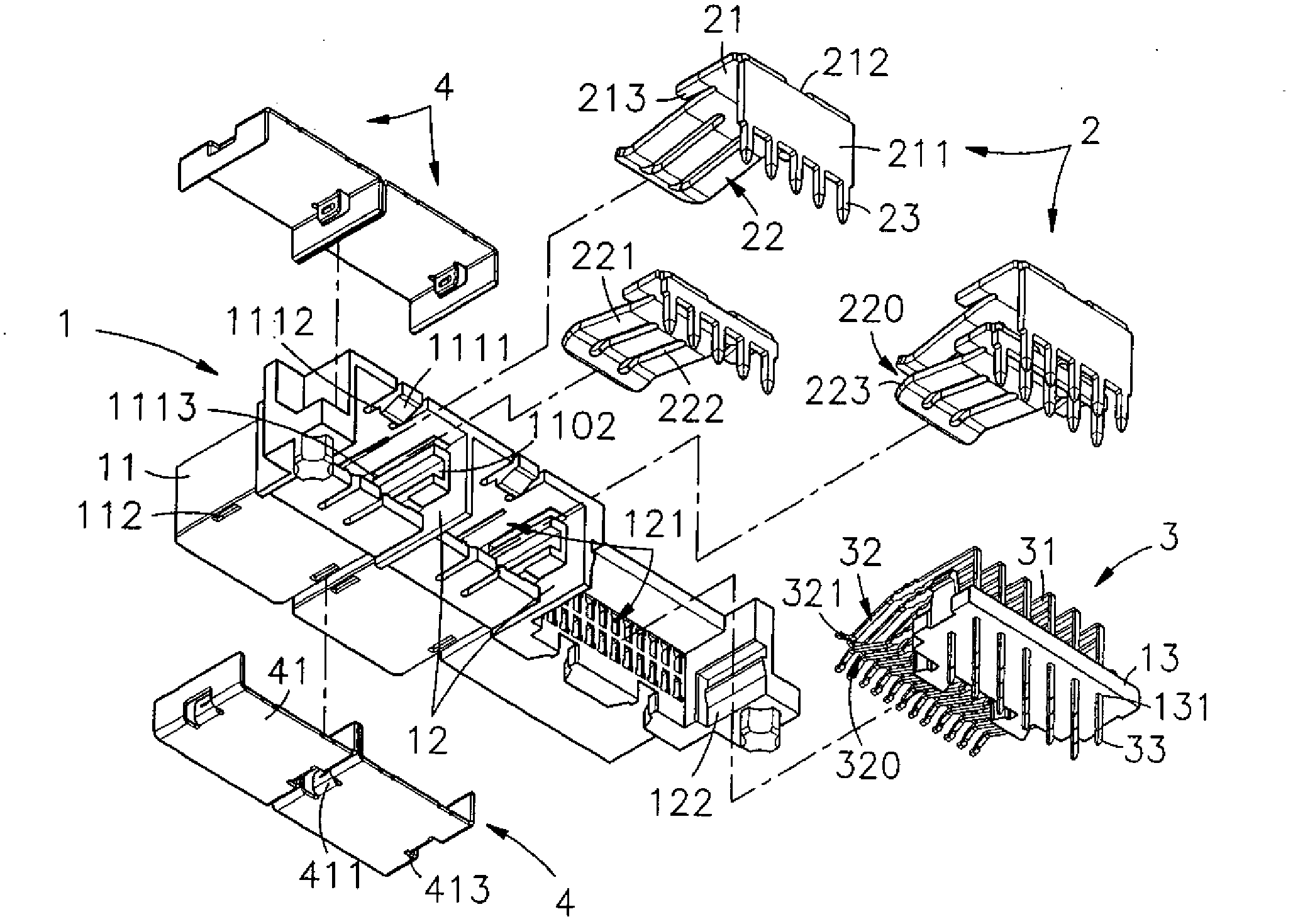

[0034] see figure 1 , figure 2 , image 3 As shown, they are the three-dimensional appearance diagram, the three-dimensional exploded view and the three-dimensional exploded view of another perspective of the present invention. It can be clearly seen from the figure that the present invention includes a seat body 1 and a plurality of terminals 2, wherein:

[0035] The seat body 1 has at least one docking portion 11 and a plurality of partition plates 12 extending behind the docking portion 11, and at least one accommodating groove 121 is formed between the partition plates 12, and the docking portion 11 is provided with a The docking space 110 of the opening 1101, and the opening 1101 is connected to each accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com