Preparation method of suspension polymerization powdered ink with core-shell structure

A technology of suspension polymerization and core-shell structure, which is applied in the field of toner manufacturing, can solve the problems of reducing the uniform charge on the surface of toner by suspension method, uneven charge on the surface of toner particles, and poor printing effect, etc., and achieve good low-temperature fixability and Environmental stability, improvement of surface charging uniformity, and the effect of good environmental stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

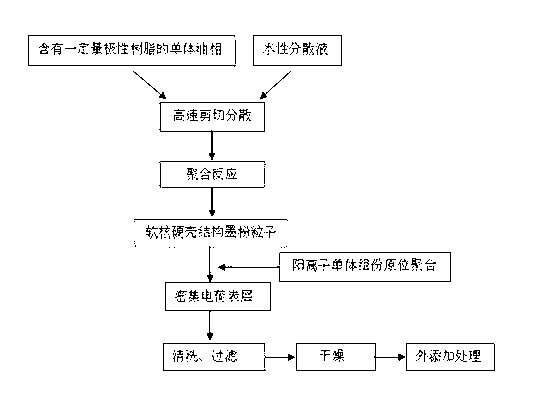

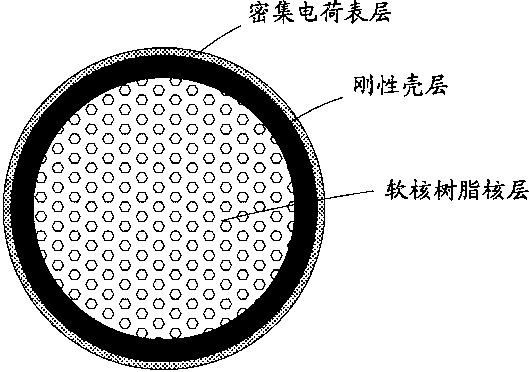

[0020] see figure 1 , figure 2 , the invention provides a method for preparing a core-shell structure suspension polymerization toner, comprising the following steps:

[0021] (1) Separately prepare a monomer oil phase containing a certain amount of polar resin, a toner soft-core resin, and an aqueous dispersion for dispersing the monomer oil phase;

[0022] (2) Add the above-mentioned monomer oil phase to the aqueous dispersion liquid, transfer it to the reactor after high-speed shear suspension granulation, and perform the first temperature-rising polymerization reaction to obtain toner particles with soft-core and hard-shell structure;

[0023] (3) Use the soft-core hard-shell structure toner particles as the core layer, add cationic monomer components, and add a water-soluble initiator to carry out the second polymerization reaction, so that the outer surface of the soft-core hard-shell structure toner particles is evenly distributed Surface layer with dense charge;

...

Embodiment 1

[0065] 86 parts of styrene, 14 parts of n-butyl acrylate, 0.6 parts of divinylbenzene, 1.0 parts of n-dodecanethiol, positive charge control agent (FCA-201-PS, styrene-acrylic acid copolymer, produced by Japan Tengcang Kasei Co., Ltd.) 2 parts, carbon black NP150 (manufactured by Degussa Corporation) 7 parts, ester wax WE-95 (manufactured by NOF Corporation) 8 parts, styrene-methacrylic acid-methyl methacrylate 10 parts of ester-α-methylstyrene copolymer (Mw is 10000, Tg is 96°C), the above components are passed through a grinding disperser at room temperature, dissolved and mixed uniformly to prepare a monomer oil phase.

[0066] In addition, an aqueous solution of 100 parts of deionized water dissolved in 13 parts of magnesium chloride was slowly added to an aqueous solution of 200 parts of deionized water dissolved in 8.3 parts of sodium hydroxide, dispersed at high speed for 1 hour, and then ultrasonically matured at room temperature for 4 hours to obtain magnesium hydroxid...

Embodiment 2

[0070] 86 parts of styrene, 14 parts of n-butyl acrylate, 0.5 parts of divinylbenzene, 0.8 parts of n-dodecanethiol, positive charge control agent (FCA-201-PS, styrene-acrylic acid copolymer, produced by Japan Tengcang Chemical Co., Ltd.) 2 parts, phthalocyanine pigment (C.I.Pigment Blue15:3, manufactured by Clariant) 5 parts, pentaerythritol tetrastearate (manufactured by Shandong Liaocheng Chemical Co., Ltd.) 8 parts, styrene- 30 parts of methacrylic acid-methyl methacrylate copolymer (Mw is 150,000, Tg is 100°C), and the above components are dissolved and mixed uniformly through grinding media at room temperature to prepare a monomer oil phase.

[0071] All the other operations are consistent with Example 1. Table 1 shows the obtained toner characteristic evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com