Crankshaft damper

A crankshaft shock absorber and crankshaft technology, which is applied in the direction of rotation vibration suppression, etc., can solve the problems of accessory belt tension fluctuations, inability to completely eliminate crankshaft torsional vibration, uneven rotation of crankshaft shock absorbers, etc., to achieve compactness and easy design Layout, effect of engine cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Crankshaft shock absorber for in-line 4-cylinder engine

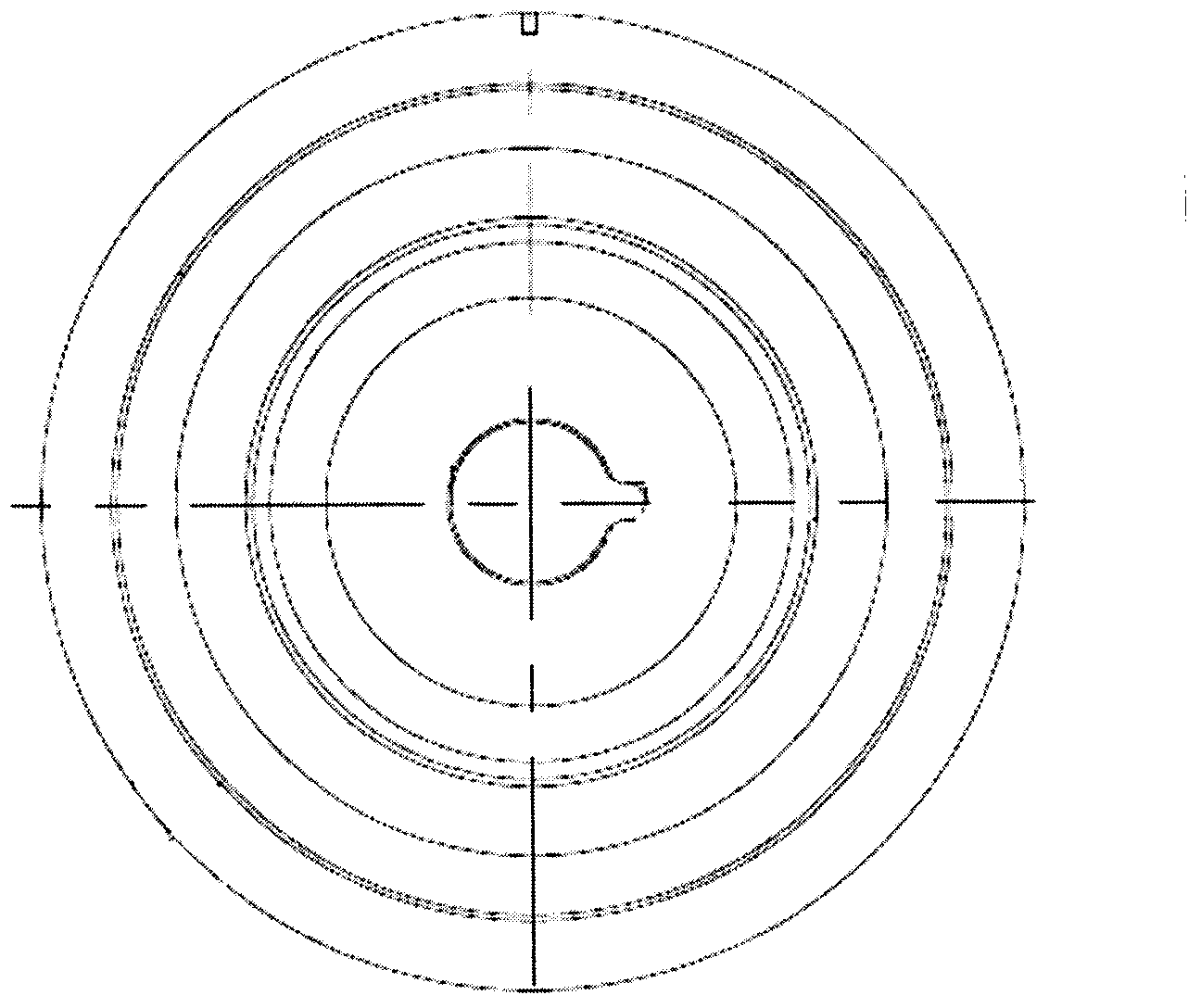

[0059] Such as Figure 9 , 10 As shown, the outer ring of the crankshaft shock absorber in Embodiment 1 is approximately elliptical as a whole, and the inner and outer rings are integrally formed without a rubber damping ring. It can be made by stamping and spinning steel plates.

Embodiment 2

[0061] Crankshaft shock absorber for in-line 4-cylinder engine

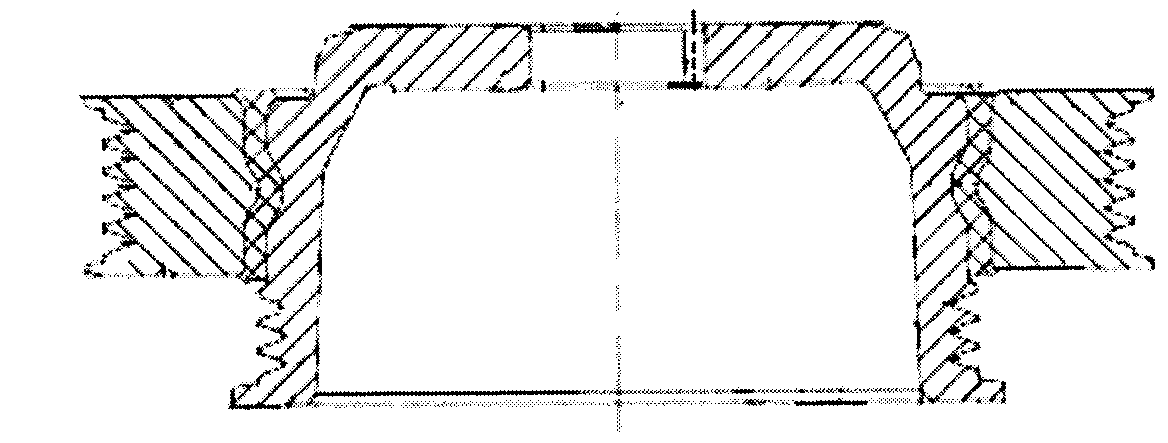

[0062] Such as Figure 11 , 12 As shown, the outer ring of the crankshaft shock absorber in Embodiment 2 is approximately elliptical as a whole, the outer ring is connected to the inner ring through a rubber damping ring, and the inner ring is connected to the crankshaft.

Embodiment 3

[0064] Crankshaft shock absorber for in-line 4-cylinder engine

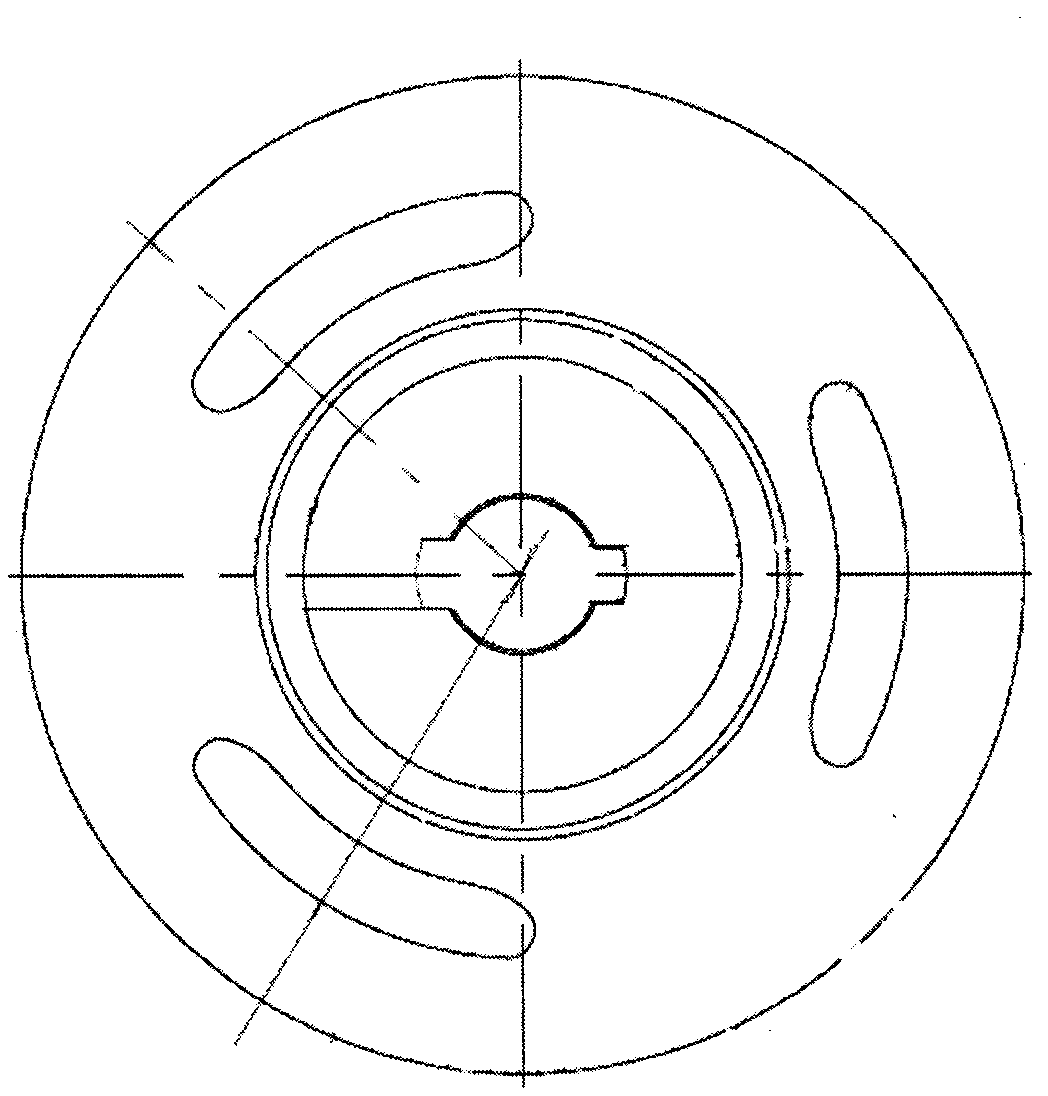

[0065] Such as Figure 13 , 14 As shown, the outer ring of the crankshaft shock absorber in Embodiment 3 is approximately elliptical as a whole, the outer ring is connected to the inner ring through a rubber damping ring, and the outer ring is connected to the crankshaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com