Yarn guide distance automatically regulating method and device therefor

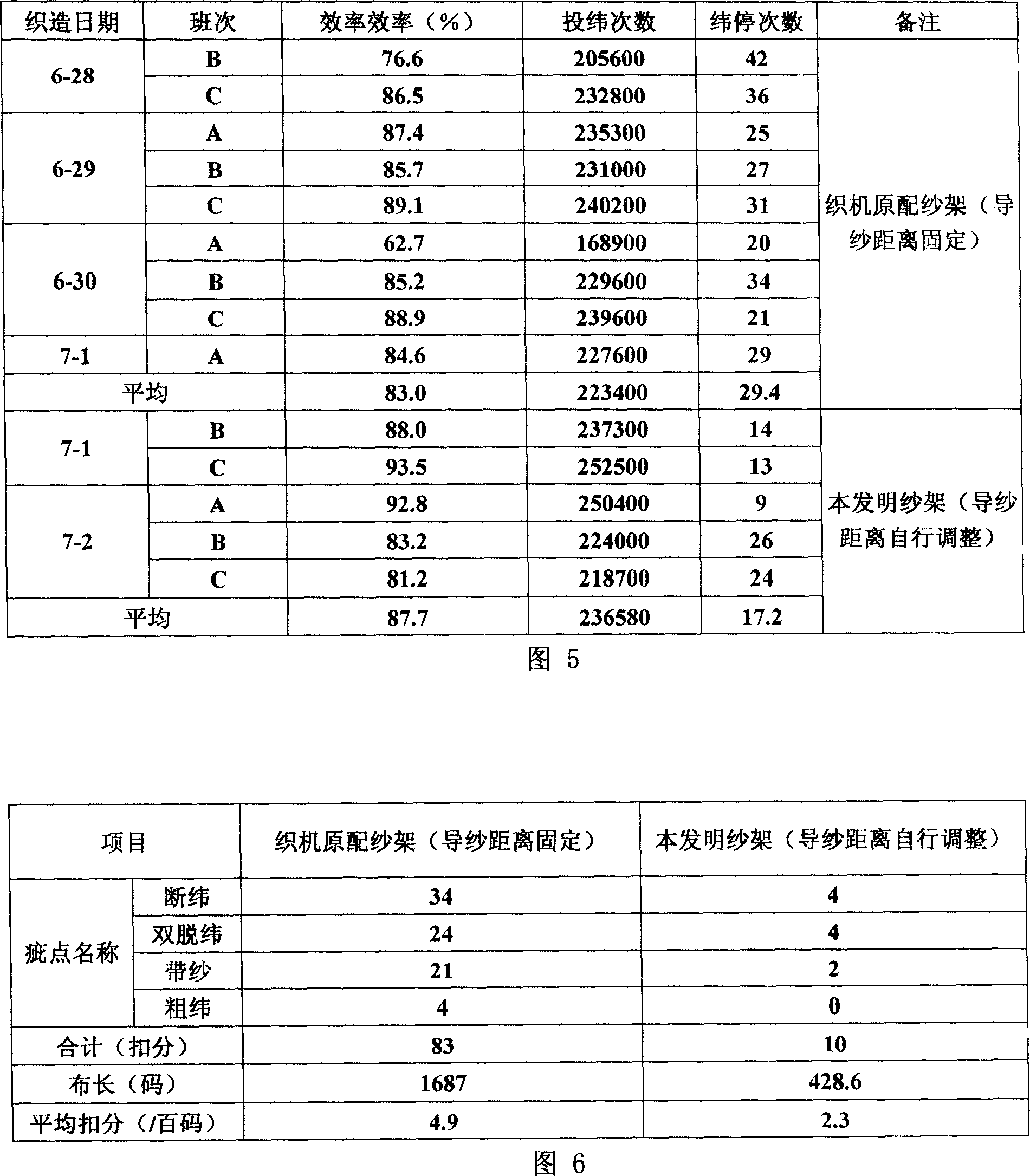

An automatic adjustment and distance technology, applied in the direction of textile, textile, papermaking, looms, etc., can solve the problems of machine parking, excessive tension fluctuation, and the yarn guide distance becomes shorter and shorter, so as to reduce the yarn tension fluctuation , Reduce the number of weft stops and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

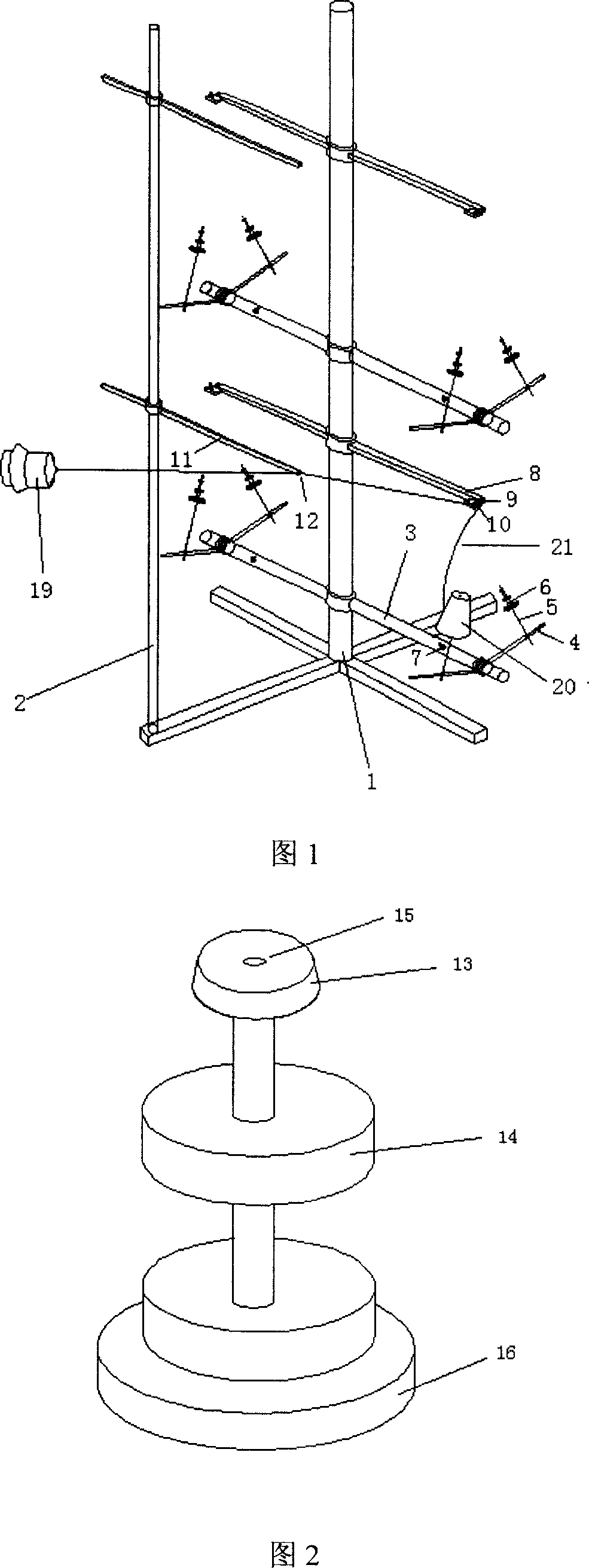

[0021] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

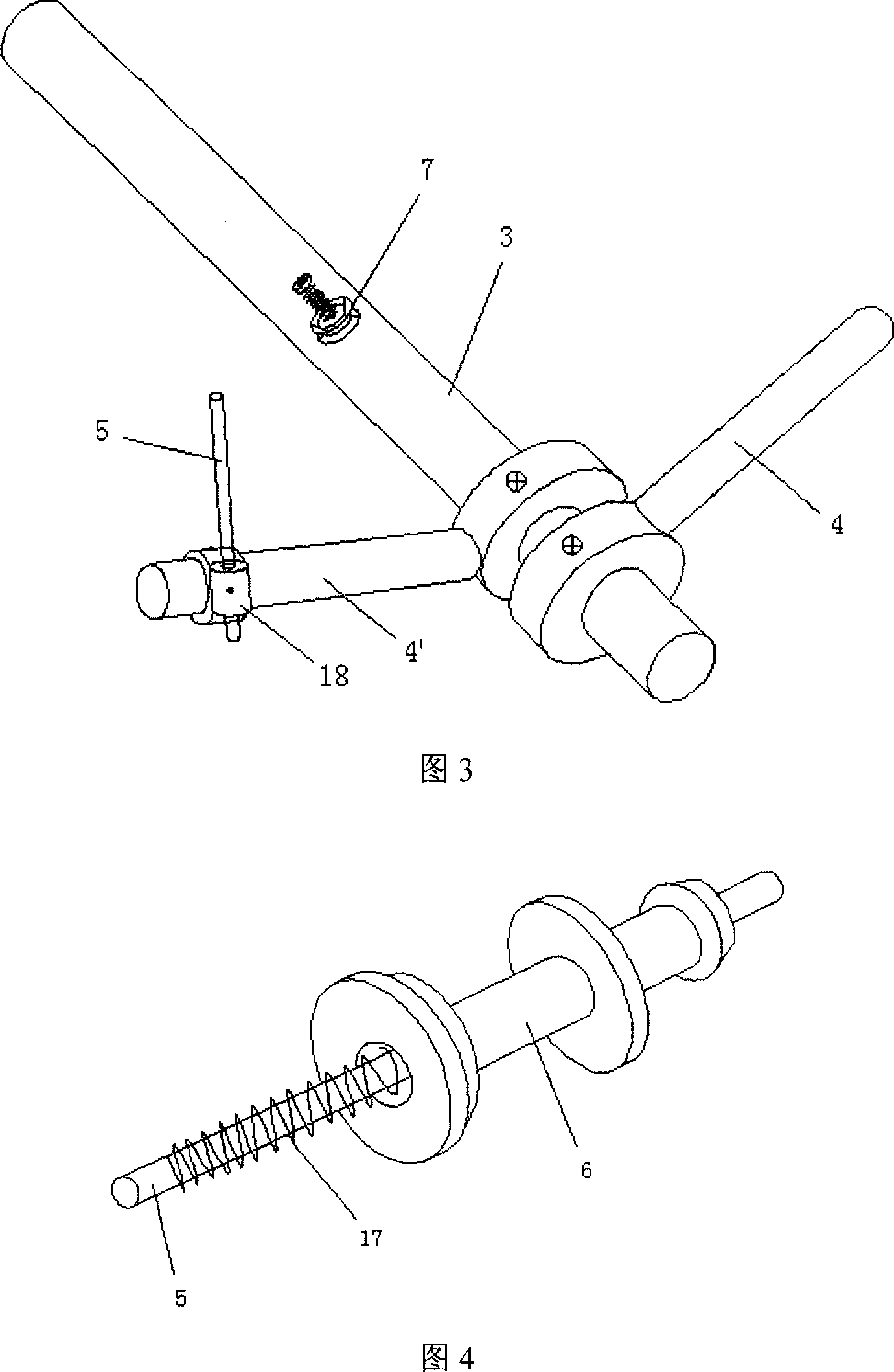

[0022] The method for automatically adjusting the yarn guide distance of the present invention is realized in this way. The bobbin support device 6 is connected to the spring 17, and the spring is compressed by the bobbin's own weight. When the bobbin is full, the spring is compressed to the maximum extent. Long, when the bobbin is decomposed into a small bobbin, the spring is as straight as possible. To achieve the purpose of long yarn guiding distance for large bobbins and short yarn guiding distance for small bobbins. The bobbin supporting device 6 is composed of three rings, the combination of the first ring 13 and the second ring 14 can satisfy the placement of tapered bobbins, and the combination of the second ring 14 and the third ring 16 can satisfy the placement of parallel bobbins.

[0023] The device of the present invention that can automatica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Diameter range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com