Roller wheel type gripper opening mechanism of gripper loom

A rapier loom, roller type technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of affecting weaving quality and efficiency, serious wear of nylon blocks, affecting weaving quality, etc., to improve weaving quality, Ensuring efficient operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

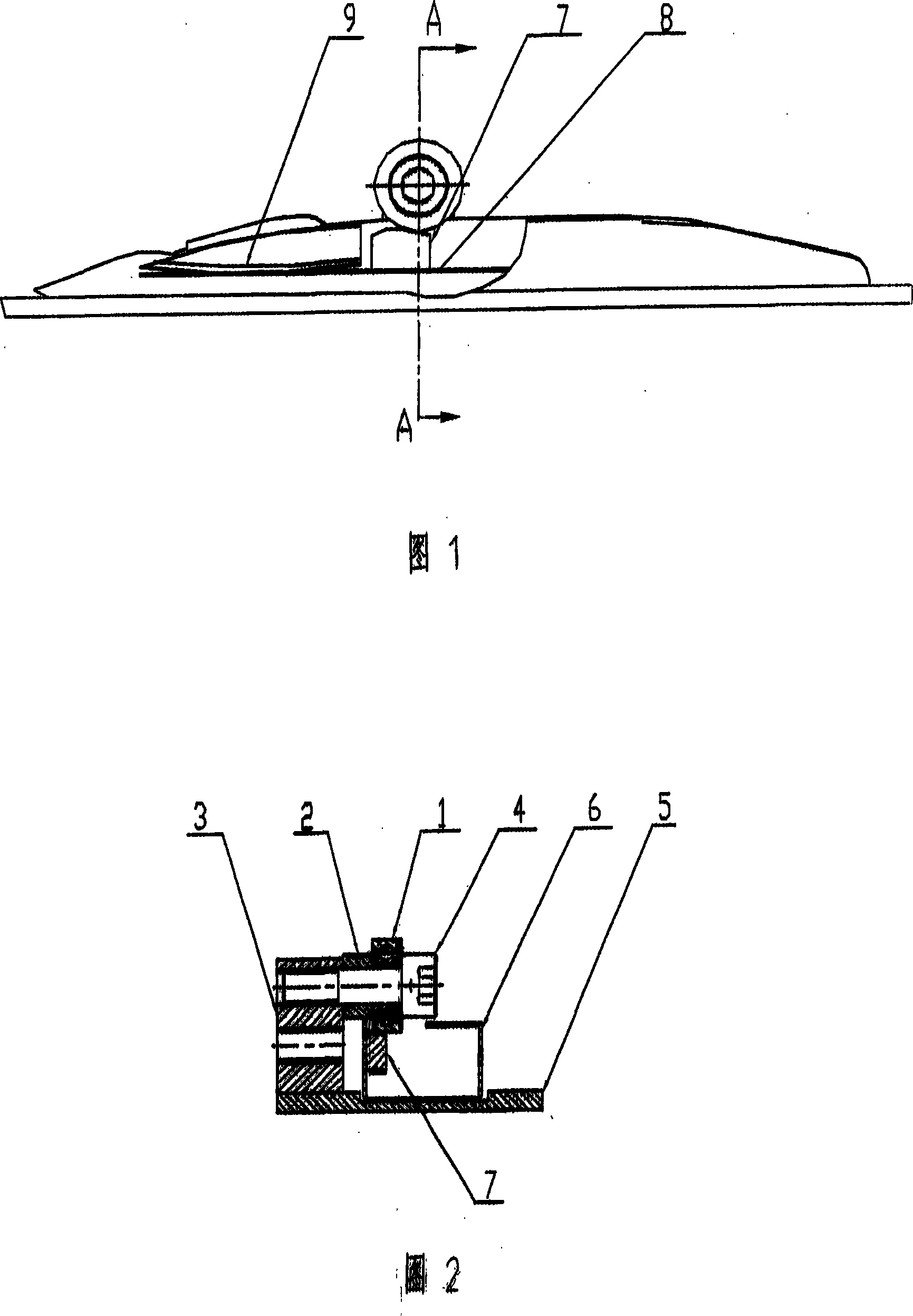

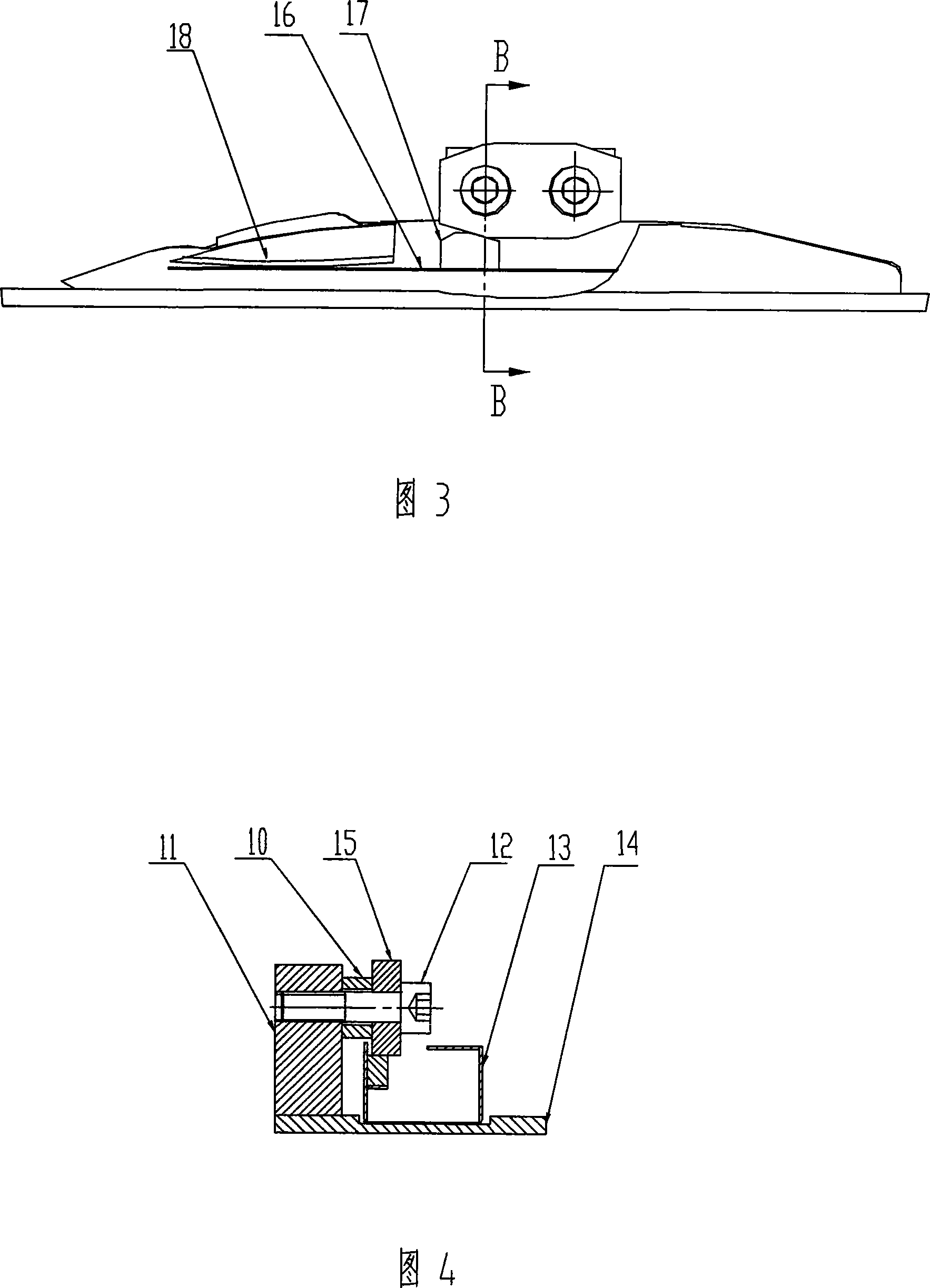

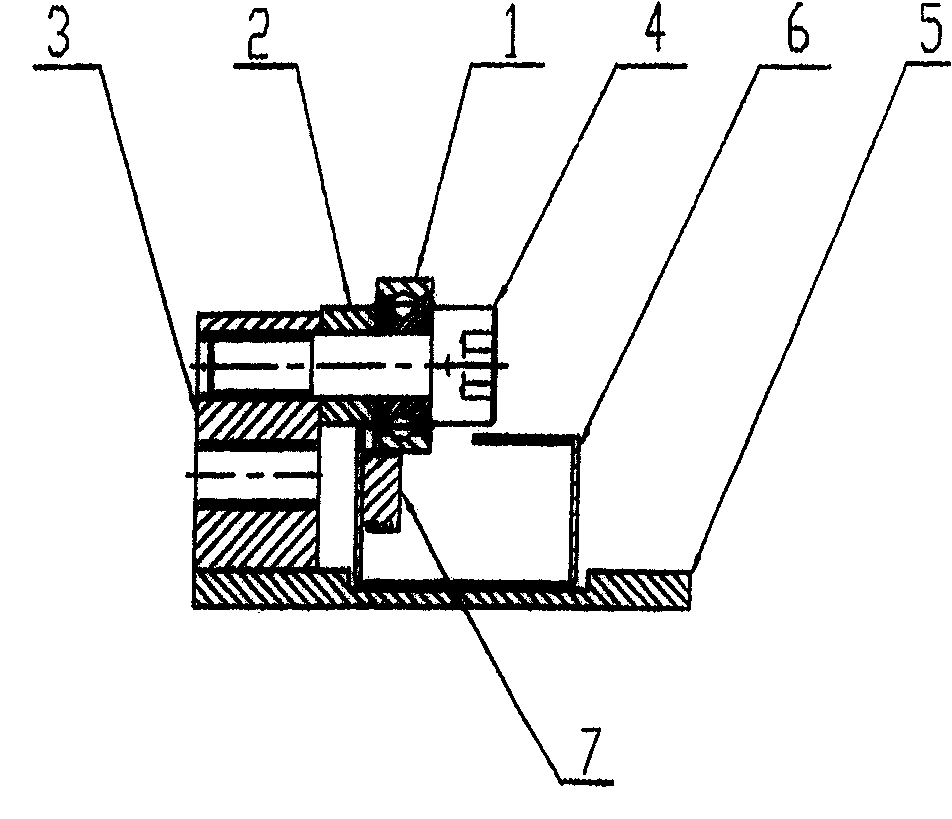

[0013] A roller-type rapier opening mechanism for a rapier loom, comprising a rolling bearing 1, a spacer 2, a rapier seat 3, a screw 4, a guide rail 5, a left rapier head 6, a rapier block 7, a yarn clamping reed 8, and a yarn clamping block 9. The rolling bearing 1 and the spacer 2 are set on the opening seat 3 through the screw 4, and the opening seat 3 is set on the guide rail 5, and the opening block 7, the yarn clamping reed 8, and the yarn clamping block 9 are set on the left sword head 6, the left rapier head 6 is slidably connected with the guide rail 5. When the left sword head 6 moves back along the guide rail 5, the sword opening block 7 installed on the sword head contacts with the rolling bearing 1, and the rolling bearing 1 presses down the sword opening block 7, driving the yarn clamping reed 8 to move downward, so that The sword head opens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com