Weft feeler

The technology of weft detector and weft detector is applied in textile, textile, papermaking, loom and other directions, which can solve the problems of increasing the labor intensity of operators, affecting normal weaving, and troublesome adjustment, and achieves flexible and convenient adjustment, simple structure, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

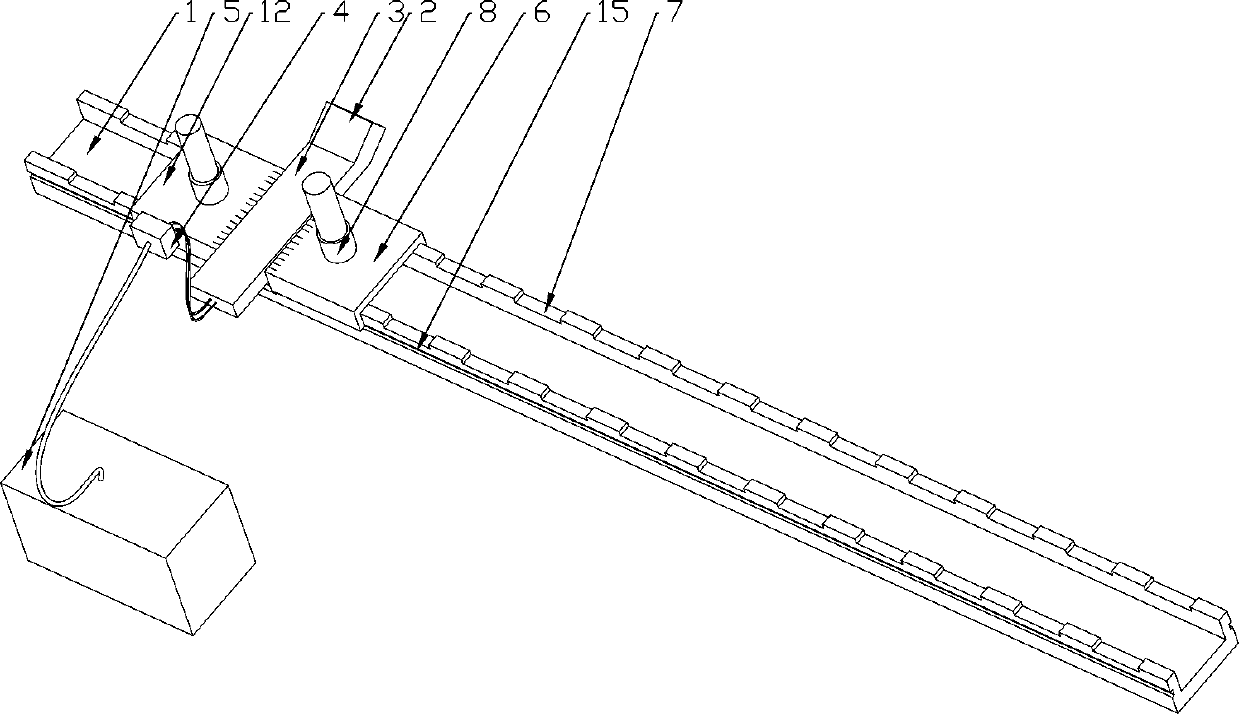

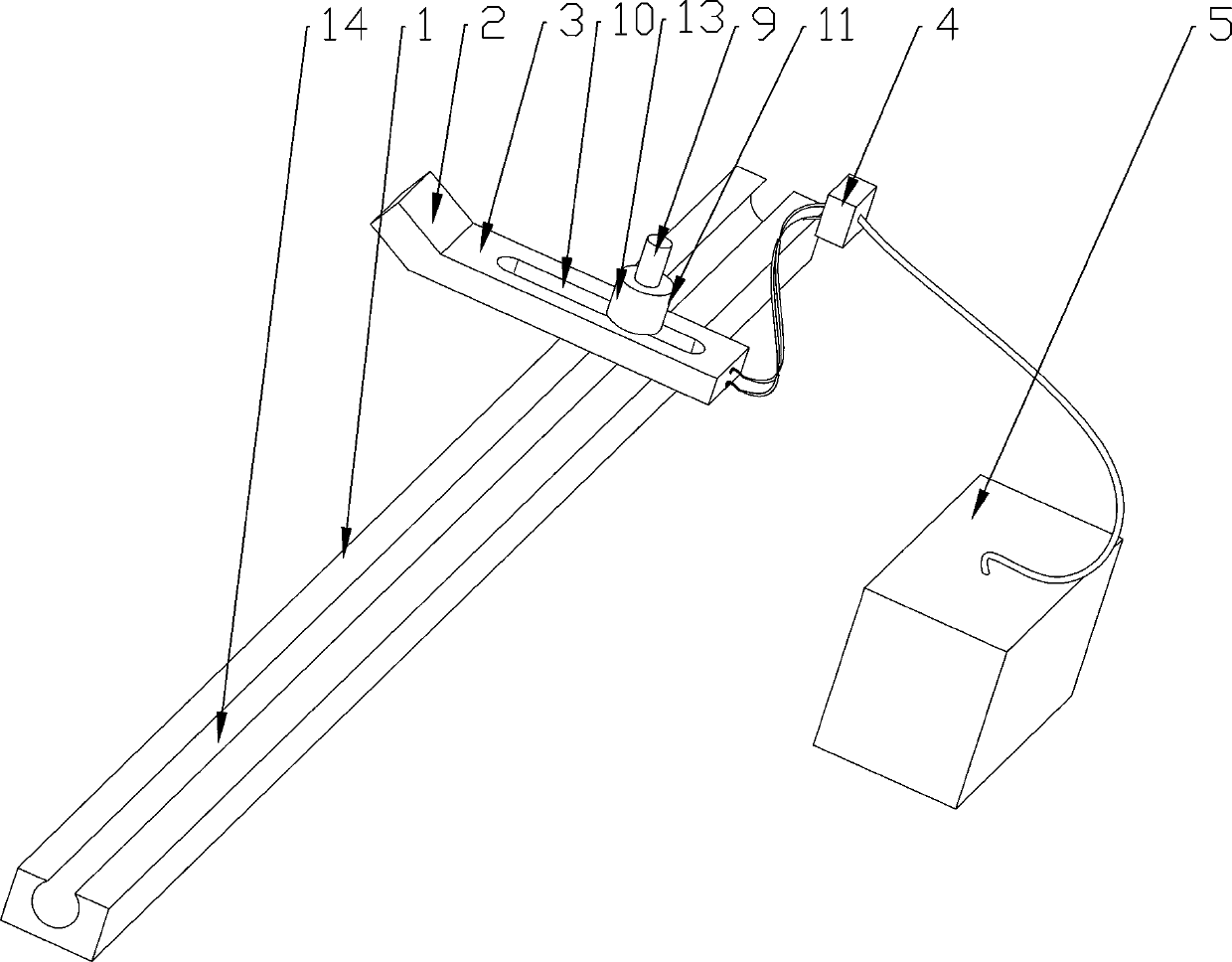

[0020] like Figure 1-2 As shown, a weft detecting device includes a sliding seat 1, a weft detecting device 2 is arranged on the sliding seat 1, and the weft detecting device 2 is installed on a weft detecting seat 3, and is electrically connected to a controller 5 through a dual time relay 4; The weft detecting seat 3 is set on the positioning groove 7 of the sliding seat 1, and is clamped by the splints 6 on both sides. The splint 6 and the weft detecting seat 3 in the positioning groove 7 are made of magnetic materials (such as magnets). And the magnetic properties of the two splints 6 and the weft detecting base 3 are opposite. When adjusted to a suitable position, the magnetic mutual attraction can be used to clamp the weft detecting base to prevent forward and backward movement. In addition, when the splint 6 is made of ordinary material, it can be directly locked and fixed by the locking bolt 8 .

[0021] The two splints 6 are provided with scales. In this way, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com