A kind of weft beating mechanism and loom

A technology of yarn arrangement and moving parts, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of unclear warp openings, increased weft stops, and reduced weaving efficiency, so as to reduce unclear openings and weft stops. Reduce and improve the effect of weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

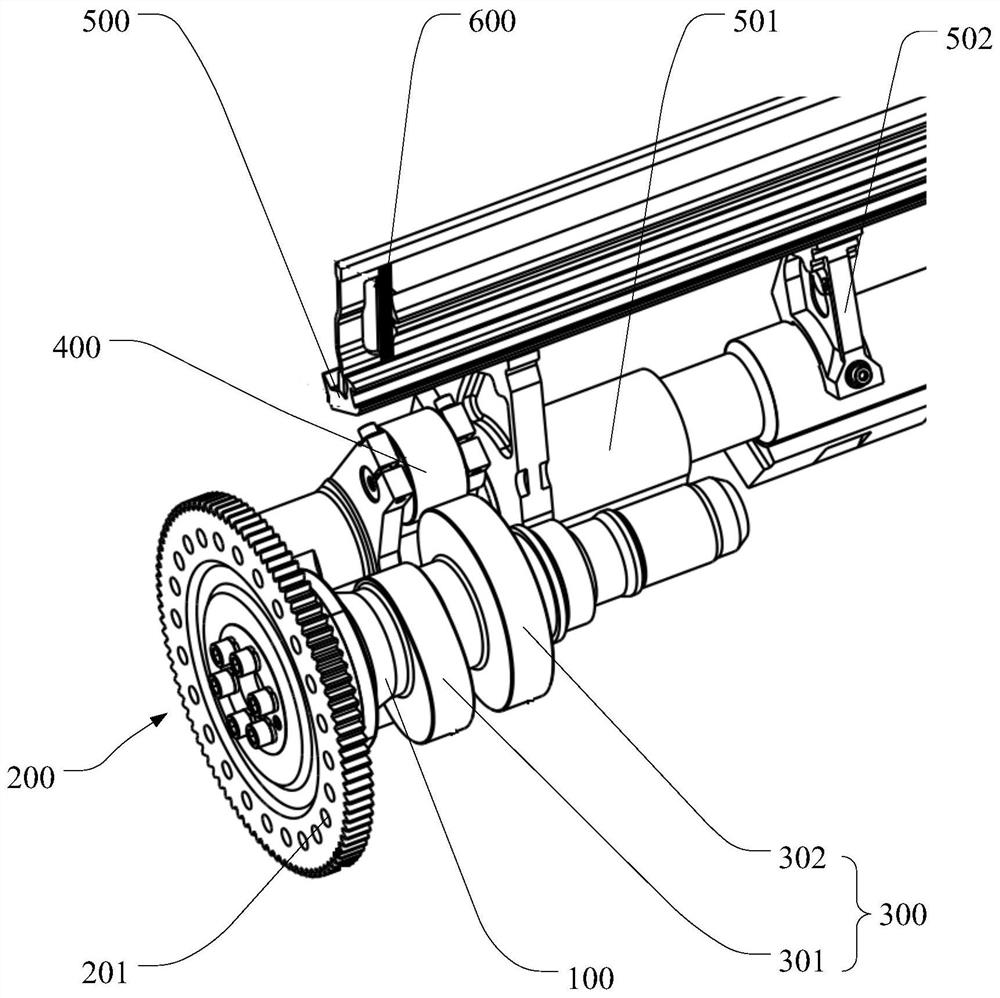

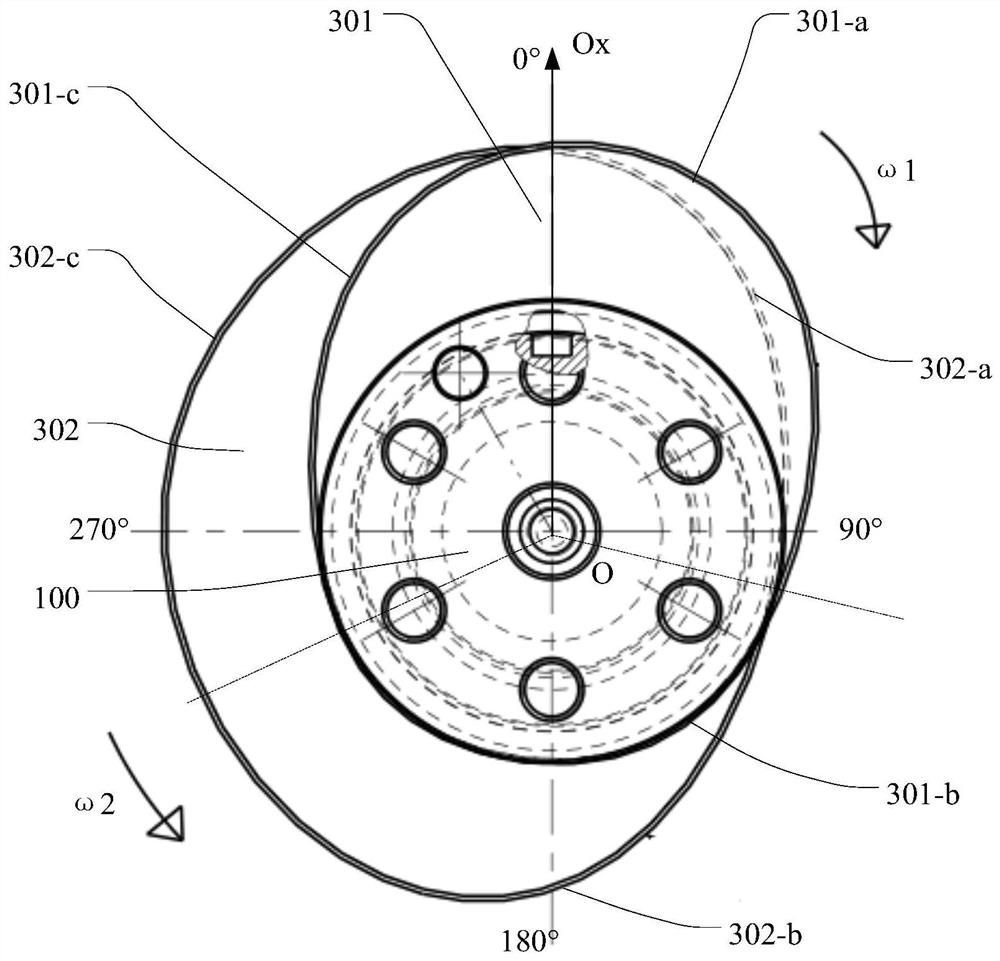

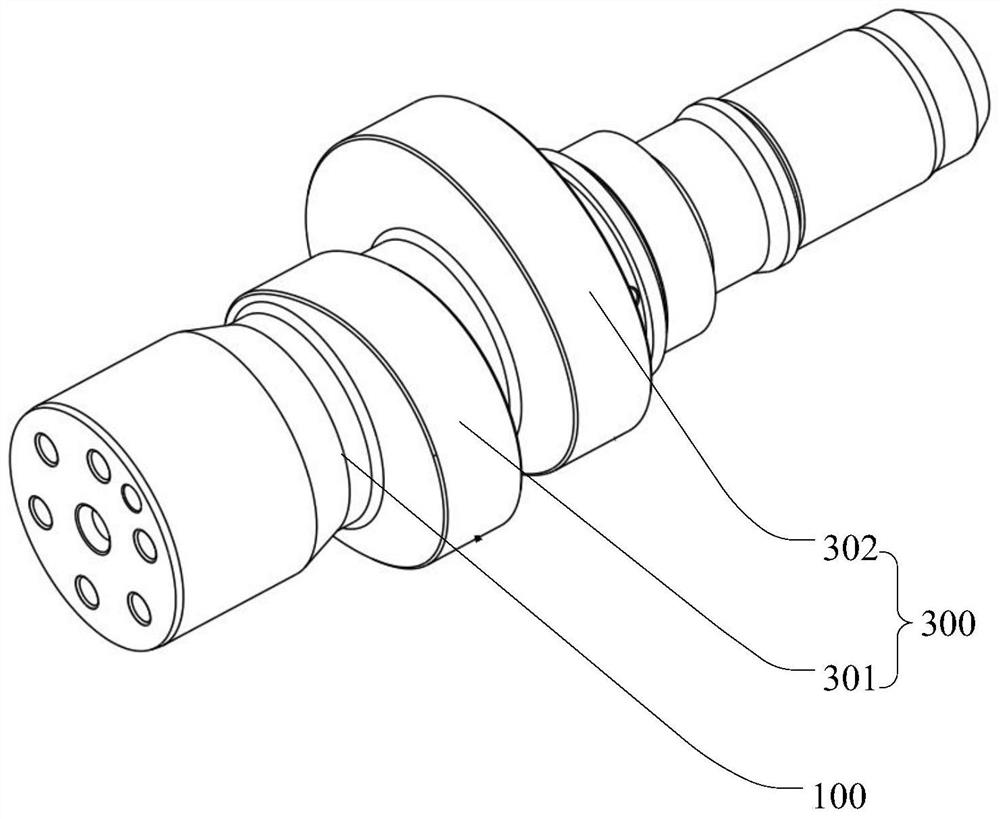

[0028] In view of this, the core of the present invention is to provide a weft beating mechanism so as to improve weaving efficiency.

[0029] The beating-up mechanism provided by the present invention drives the reed to perform the beating-up action and the return action through the conjugate cam. What is different from the prior art is that the reed can perform the swinging yarn arrangement after the return action is completed. The swing yarn arrangement is specific. For the reciprocating swing of the reed, through the reciprocating swing of the reed, the defects on the warp yarn and sizing defects are cleaned up, the warp yarn is straightened out, and then the follow-up beating action is performed, thereby reducing the phenomenon of unclear shedding and optimizing the weft insertion condition , reducing the number of weft stops and improving weaving efficiency. An overview of the invention in this section

[0030] The following will clearly and completely describe the tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com