Water-borne non-ionic polyurethane antistatic coating and preparation method and application thereof

A non-ionic polyurethane, anti-static technology, used in polyurea/polyurethane coatings, coatings, conductive coatings, etc., can solve the problem that cannot meet the physical properties and triboelectric charging properties of water-based polyurethane, and cannot meet the requirements of printers and other electrophotographic equipment. and other problems, to achieve the effect of flexible and variable addition amount, good triboelectric charging performance, and adjustable triboelectric charging amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

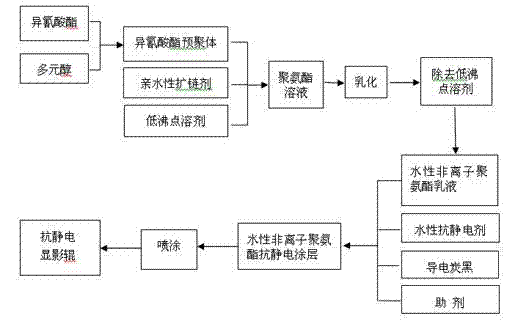

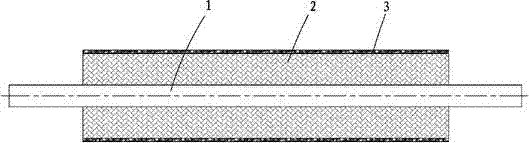

[0046] See figure 1 The present invention provides a method for preparing the above-mentioned water-based non-ionic polyurethane antistatic coating, which includes the following steps:

[0047] (1) Preparation of water-based non-ionic polyurethane emulsion:

[0048] Add 20-40% isocyanate and 50-70% polyol to the reaction kettle in sequence, and stir and react at 80-100°C for 1-3 hours to obtain isocyanate prepolymer;

[0049] The obtained isocyanate prepolymer is cooled to 45-55°C, and then 5-15% non-ionic hydrophilic chain extender, 5-15% small molecule chain extender and the total amount of the above mixture are 30-100% low Chain extension with boiling point solvent to obtain polyurethane solution;

[0050] After high-speed shearing, it is emulsified in water (concentration 1%) containing a salt-forming agent, and the low-boiling point solvent is removed in a vacuum to obtain an aqueous non-ionic polyurethane emulsion.

[0051] (2) Preparation of water-based non-ionic polyurethane an...

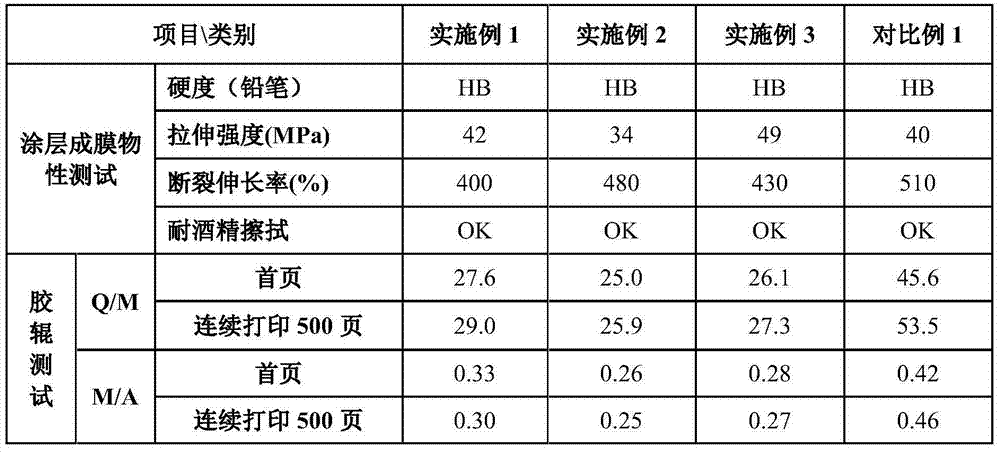

Embodiment 1

[0059] (1) Preparation of water-based non-ionic polyurethane emulsion:

[0060] Add 23.0g of toluene diisocyanate and 67.5g of water-soluble polyoxyethylene glycol 2000 into the reaction kettle successively, stir and react at 80-100℃ for 1-3 hours to obtain isocyanate prepolymer; lower the temperature to about 45℃, Add 3.7g diethylene glycol, 5.8g triethanolamine and appropriate amount of acetone for chain extension to obtain polyurethane solution; emulsify in water containing salt-forming agent through high-speed shearing, remove low-boiling solvent in vacuum, and finally obtain water-based Ionic polyurethane emulsion.

[0061] (2) Preparation of water-based non-ionic polyurethane antistatic liquid:

[0062] In the water-based non-ionic polyurethane emulsion obtained in step (1), 10wt% conductive carbon black, 5wt% water-based quaternary ammonium salt antistatic agent, 1wt‰ wetting agent BYK 344, 1wt‰ are added at a lower stirring speed Leveling agent TEGO410 is a water-based non-...

Embodiment 2

[0067] (1) Preparation of water-based non-ionic polyurethane emulsion:

[0068] Add 35.0g of isophorone diisocyanate and 57.2g of water-soluble polyoxyethylene glycol 1000 to the reaction kettle successively, stir and react at 80-100℃ for 1-3 hours to obtain isocyanate prepolymer; lower the temperature to about At 50℃, add 4.8g diethylene glycol, 3.0g triethanolamine and appropriate amount of acetone for chain extension to obtain polyurethane solution; high-speed shear emulsification in water containing salt-forming agent, vacuum removal of low-boiling solvent, and finally Water-based non-ionic polyurethane emulsion.

[0069] Steps (2) and (3) are the same as in Example 1, and the specific test data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com