Electrostatic additive for powder coating as well as preparation method and application thereof

A powder coating and additive technology, applied in powder coatings, conductive coatings, polyester coatings, etc., can solve problems such as bad smell of sterically hindered tertiary amines, unstable and unstable particle surface electrical properties, and achieve the elimination of Faraday phenomenon and good Triboelectric performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

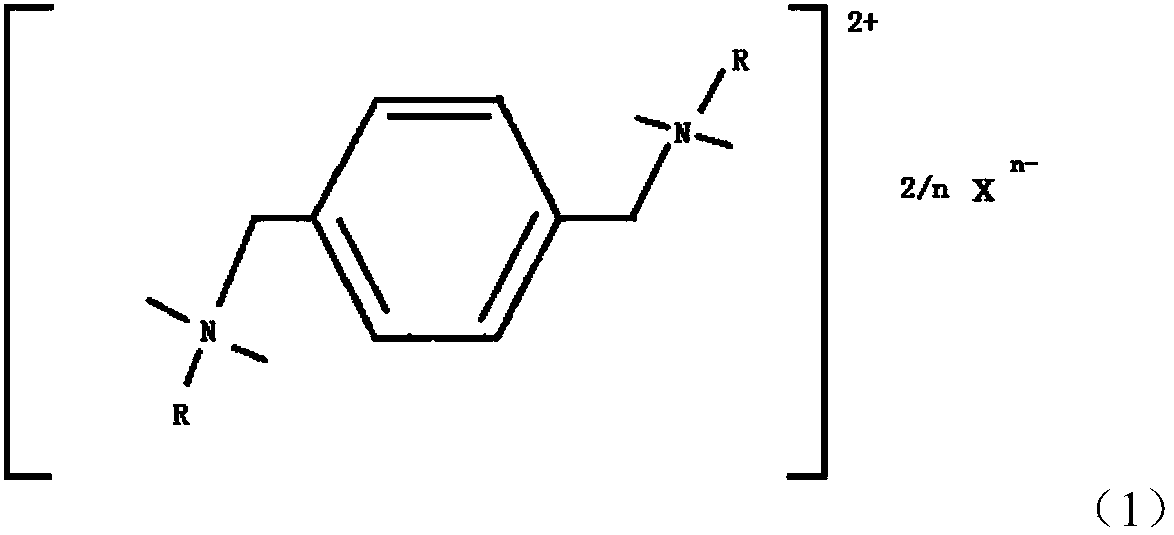

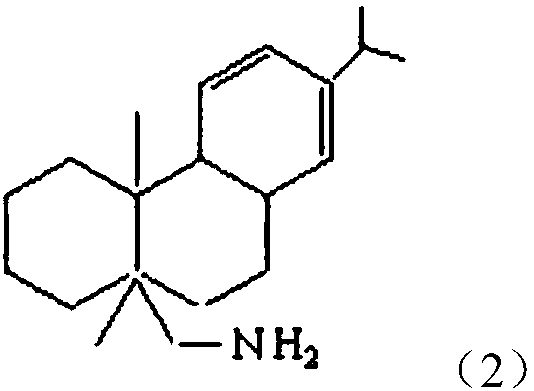

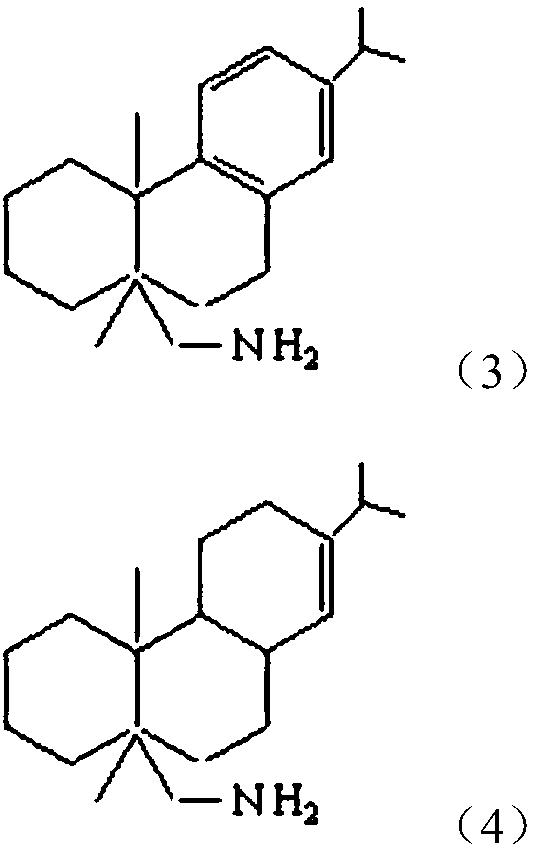

[0036] Synthesis of NR-C

[0037] Dissolve heavy 144g rosin amine in 350ml of 95% ethanol, slowly add 154g of formic acid with a concentration of 2.5 times or more in terms of primary amine moles and control the temperature below 40°C under cooling conditions, and control the temperature below 40°C; Then add 120g of formaldehyde with a concentration of 36% or more than 1.5 times the number of moles of primary amine, heat up to 70°C and reflux for 5 hours until the reaction is complete, then distill and separate the solvent ethanol and formic acid, cool to 40°C and add sodium hydroxide to neutralize to pH 10, washed with nearly saturated sodium chloride water to pH 8, extracted the oil layer with benzene, and collected about 125 g of rosin tertiary amine product by vacuum distillation.

[0038] Add the above-mentioned 63g rosin tertiary amine product into 150ml of dichloromethane, and heat until completely dissolved. Add 88ml of 20% 1,4-dichlorobenzyl dichloromethane solution ...

Embodiment 2

[0040] Preparation of NR-S

[0041] 40 grams of NR-C, that is, the rosin-based bis-quaternary ammonium chloride prepared in Example 1, was dispersed in 200 ml of 3M sodium sulfate aqueous solution, stirred for 2 hours at 50 ° C and a rotating speed of 1200 r / min, filtered, and removed. Wash with ionized water until the conductivity of the filtrate is lower than 100 μS, and dry to obtain rosin-based bis-quaternary ammonium sulfate product code name NR-S.

Embodiment 3

[0043] Preparation of NR-M

[0044] With reference to Example 2, 40 grams of NR-C, that is, the rosin-based bis-quaternary ammonium chloride salt prepared in Example 1, was dispersed in 200 ml of 1M sodium molybdate aqueous solution, and at 50 ° C, the rotating speed was 1500 r / min. Stir for 3 hours, filter, wash with deionized water until the conductivity of the filtrate is lower than 100 μS, and dry to prepare the rosin-based bisquaternary ammonium molybdate product code name NR-M.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com