Core-shell type carbon microspheres and preparation method and application thereof

A carbon microsphere, core-shell type technology, which is applied in the field of surface functional modification of carbon microspheres, can solve the problems such as the lack of research on the flame retardancy of carbon microspheres, the inability to improve the compatibility well, and the increase of surface functional group content. , to achieve the effect of stable product performance, wide application range and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

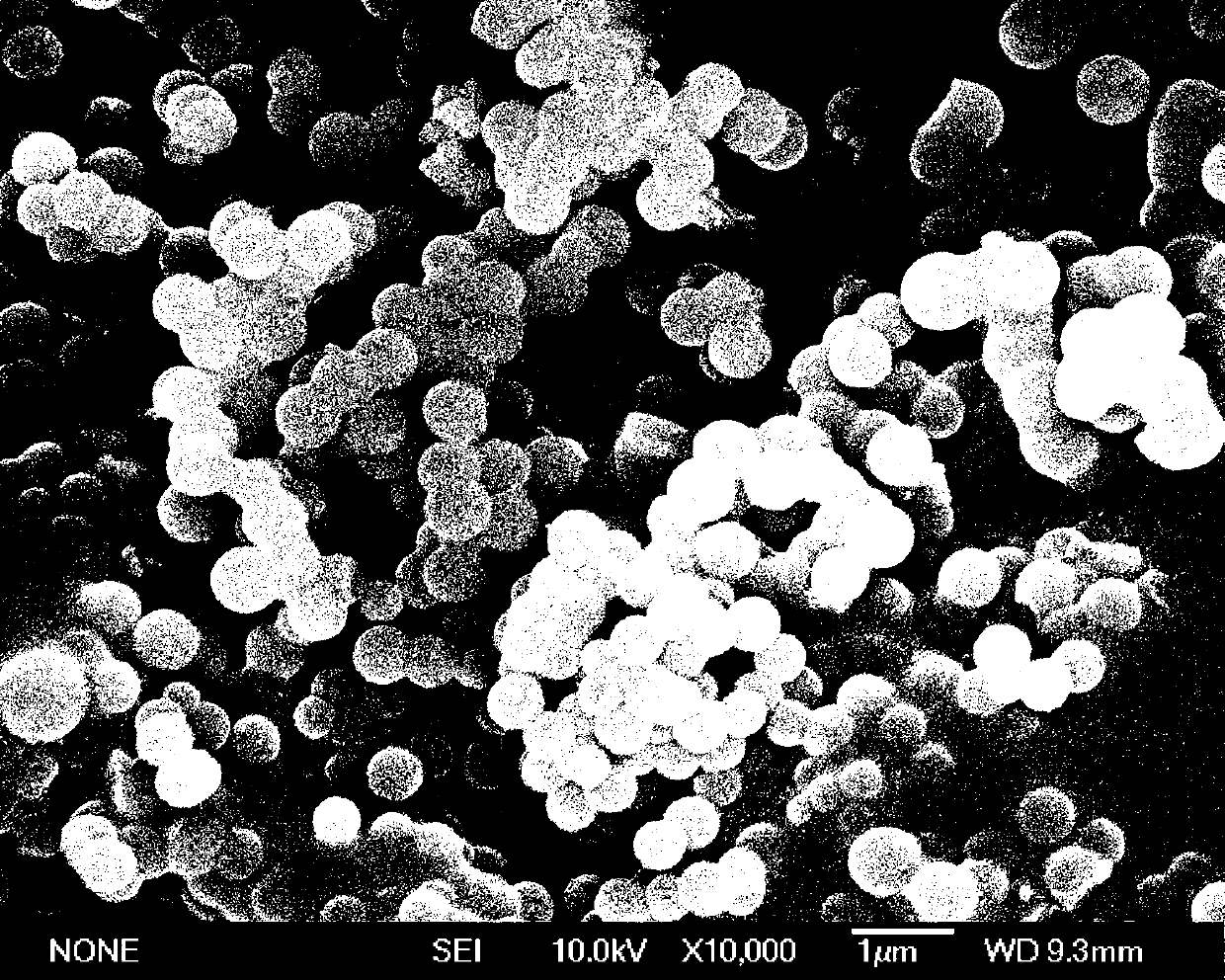

[0028] 48.6g of glucose was added to 600mL of deionized water to prepare a 0.45mol / L glucose solution, added to the autoclave, heated to 300°C under stirring, pressure 8MPa, stirred at constant temperature for 12h, and cooled to room temperature naturally. The reaction product was suction filtered and washed with deionized water until the pH value was 7, and the filter cake was dried at 120° C. for 300 min to obtain carbon microspheres.

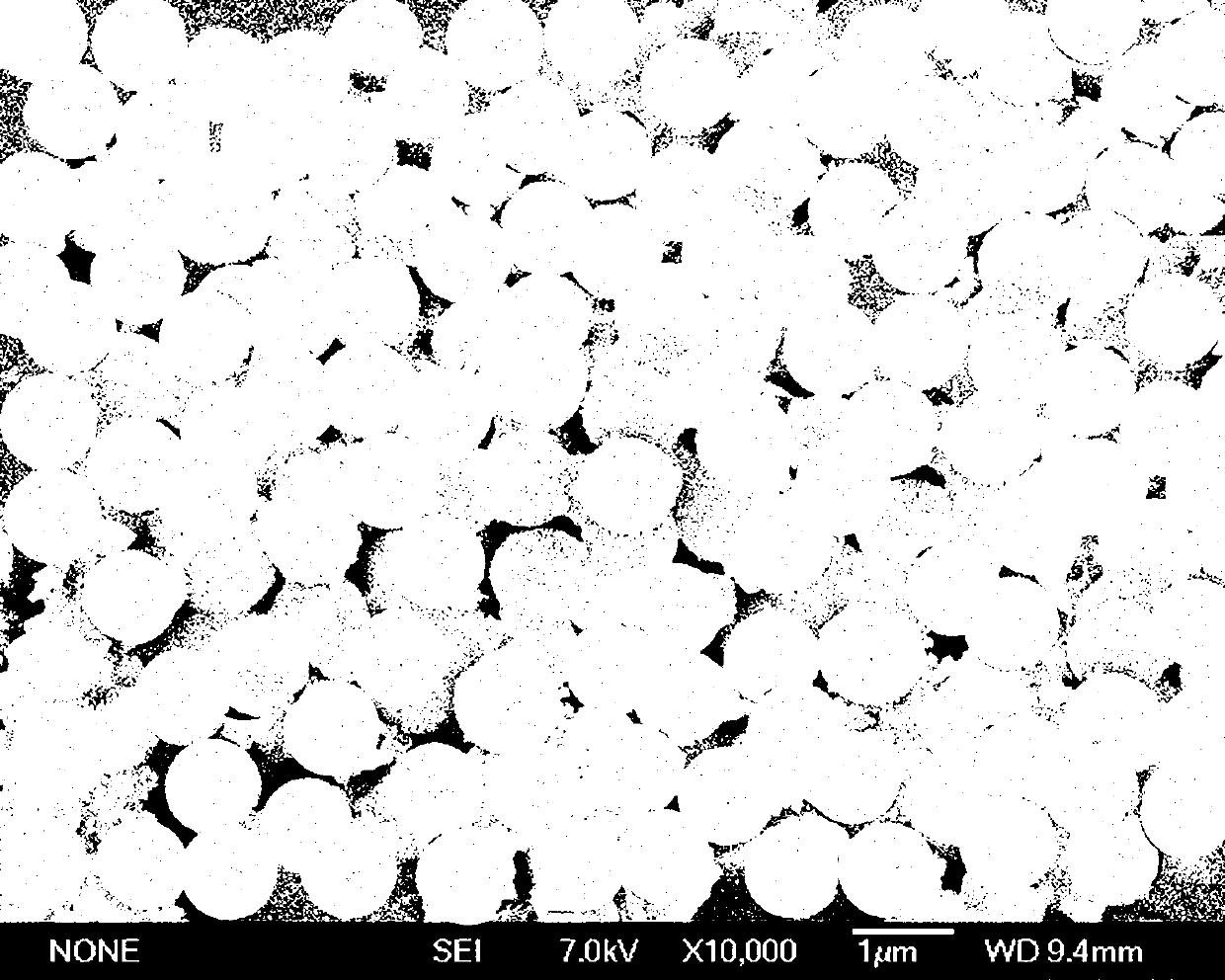

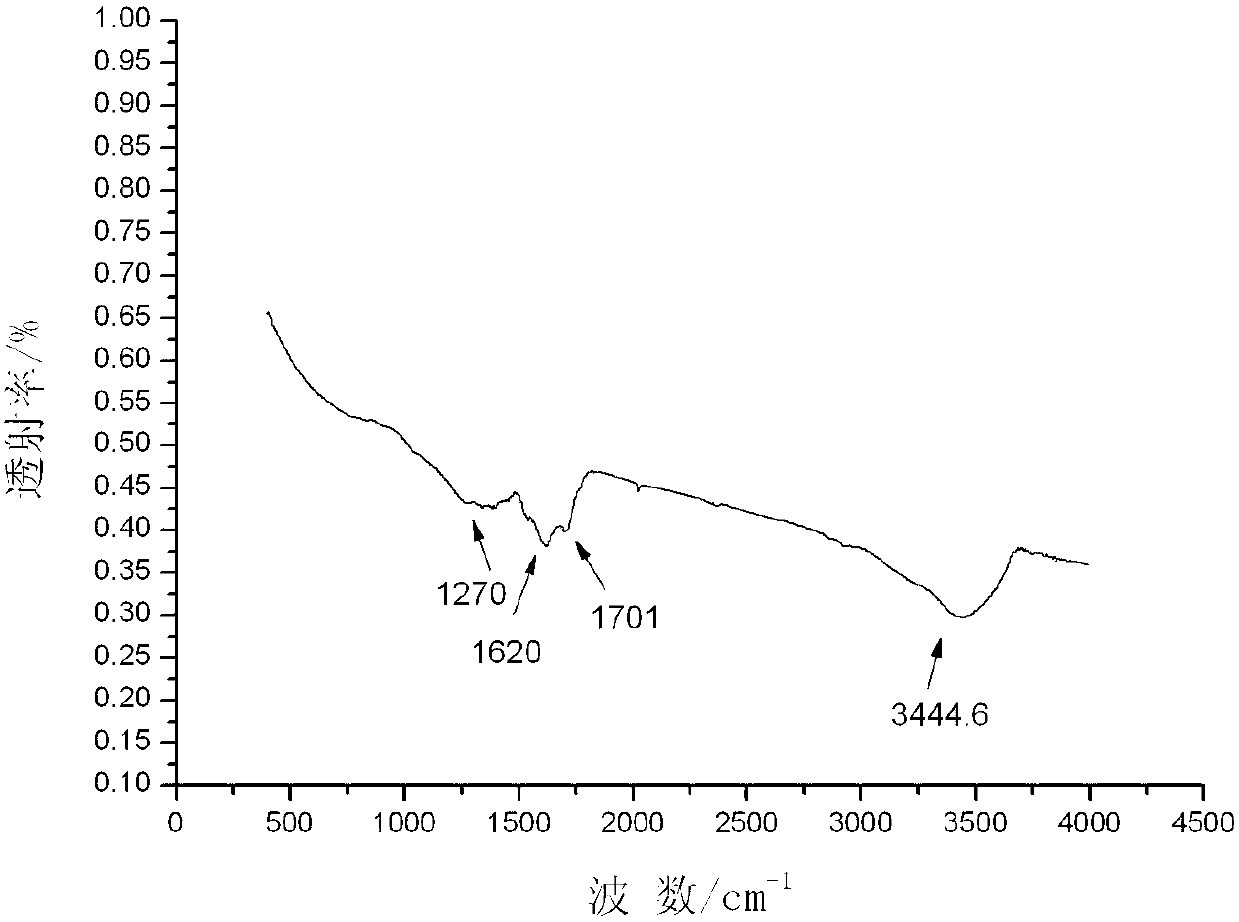

[0029] Weigh 10g of terephthalic acid and dissolve it in 300mL of N,N-dimethylformamide, add it to a 500mL four-necked flask, add 50mL of ethylene glycol, 10g of carbon microspheres, 1.3g of antimony trioxide in turn, and stir under stirring. The temperature was raised to 140° C. under nitrogen protection, and 5 mL of OP-10 was slowly added to the four-necked flask, and the reaction was carried out for 7 h. The product was washed with absolute ethanol and filtered until the washing liquid was clarified, then washed with deionized water, and t...

Embodiment 2

[0033]54g of glucose was added to 600mL of deionized water to prepare a 0.5mol / L glucose solution, added to the autoclave, heated to 280°C under stirring, under a pressure of 7MPa, stirred at a constant temperature for 8h, and cooled to room temperature naturally. The reaction product was suction filtered and washed with deionized water until the pH value was 7, and the filter cake was dried at 120° C. for 300 min to obtain carbon microspheres.

[0034] Weigh 10g of terephthalic acid and dissolve it in 300mL of N,N-dimethylformamide, add it to a 500mL four-necked flask, add 100mL of ethylene glycol, 20g of carbon microspheres, and 3g of antimony trioxide in turn, and stir to pass through. Under nitrogen protection, the temperature was raised to 160 °C, and 10 mL of OP-10 was slowly added to the four-necked flask, and the reaction was carried out for 8 h. The product was washed with absolute ethanol and filtered until the washing liquid was clarified, then washed with deionized...

Embodiment 3

[0036] 32.4g of glucose was added to 600mL of deionized water to prepare a 0.4mol / L glucose solution, added to the autoclave, heated to 260°C under stirring, pressure 6.5MPa, stirred at constant temperature for 12h, and cooled to room temperature naturally. The reaction product was suction filtered and washed with deionized water until the pH value was 7, and the filter cake was dried at 120° C. for 300 min to obtain carbon microspheres.

[0037] Weigh 10g of terephthalic acid and dissolve it in 300mL of N,N-dimethylformamide, add it to a 500mL four-necked flask, add 50mL of ethylene glycol, 10g of carbon microspheres, and 2g of antimony trioxide in turn, and stir to pass through. Under nitrogen protection, the temperature was raised to 180 °C, and 8 mL of OP-10 was slowly added to the four-necked flask, and the reaction was carried out for 7 h. The product was washed with absolute ethanol and filtered until the washing liquid was clarified, then washed with deionized water, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com