Aluminum hydroxide and preparation method thereof

An aluminum hydroxide and oxide technology, applied in chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., can solve the problems of dispersion of pore size distribution, large bubble size, clogging of distribution plate products, etc., and achieve concentrated pore distribution. , the effect of large specific surface area and fast circulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

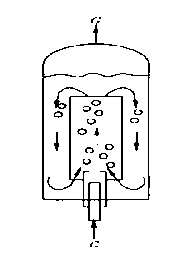

Method used

Image

Examples

Embodiment 1

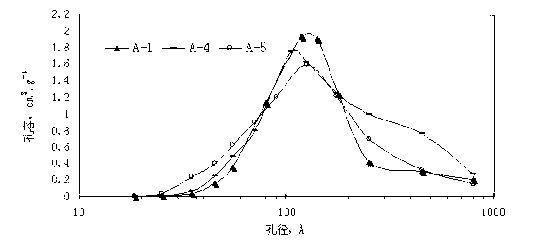

[0033] Take industrial-grade aluminum hydroxide powder and industrial-grade sodium hydroxide to configure a concentration of 365 gAl 2 o 3 / L concentrated sodium metaaluminate solution, then diluted to a concentration of 28gAl 2 o 3 / L of sodium metaaluminate solution, add organic pore expander alkylphenol and ethylene oxide condensation product (OP-10) and polyoxyethylene sorbitan monooleate (T-80), where OP- The weight ratio of 10 to T-80 is 60:40, the amount of pore expander accounts for 0.6% of the weight of sodium metaaluminate, diesel oil is used as the defoamer, and the amount of defoamer is 0.6% of the weight of the pore expander. The solution is added to the jet loop reactor, the mixed gas of carbon dioxide and air is injected into the reactor, CO 2 The volume concentration is 60%, and the average gas holdup rate is controlled to 0.20, so that the fluid is uniformly mixed in the reactor and forms a circulation flow. When the gel stops. The slurry was washed with d...

Embodiment 2

[0035] The preparation method of aluminum hydroxide is identical with embodiment 1, and its difference is to control air and CO 2 The gas holdup of the mixed gas is 0.15, and the circulation velocity is 1.80 m / s. The physical and chemical properties of the obtained alumina A-2 are shown in Table 1.

Embodiment 3

[0037] The preparation method of aluminum hydroxide is identical with embodiment 1, and its difference is to control air and CO 2 The gas holdup of the mixed gas is 0.18, and the circulation velocity is 1.90 m / s. The physical and chemical properties of the obtained alumina A-3 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com