Pulse drive circuit of semiconductor laser based on avalanche transistor

A technology of pulse driving and driving circuit, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of high cost, inconvenient parameter adjustment, difficult loop optimization and coordination, etc., and achieve the effect of ensuring synchronization and compact overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings and specific embodiments.

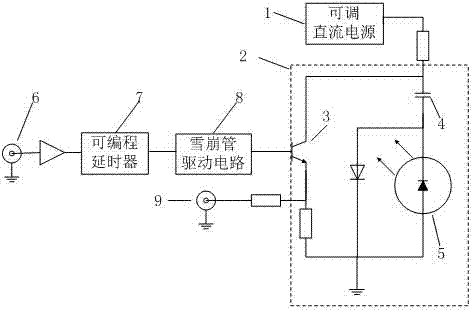

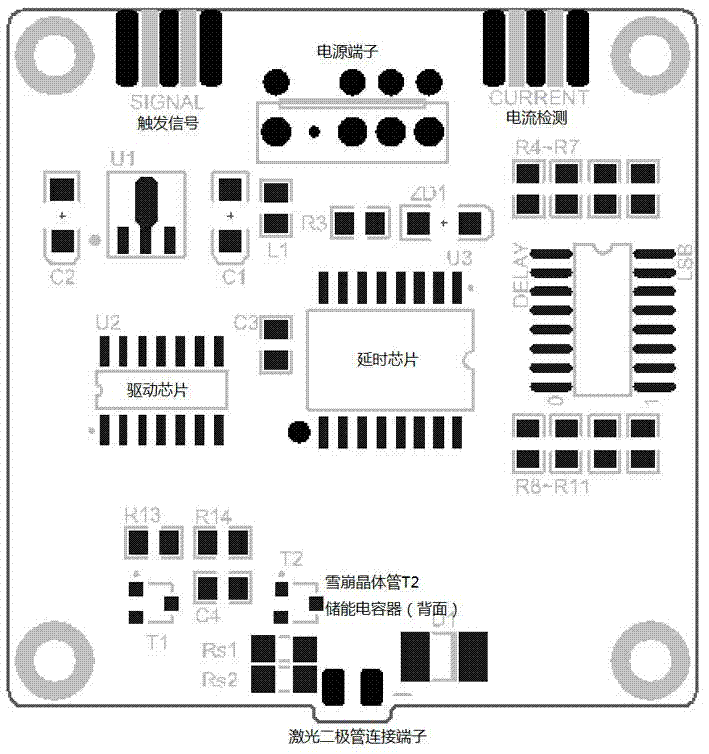

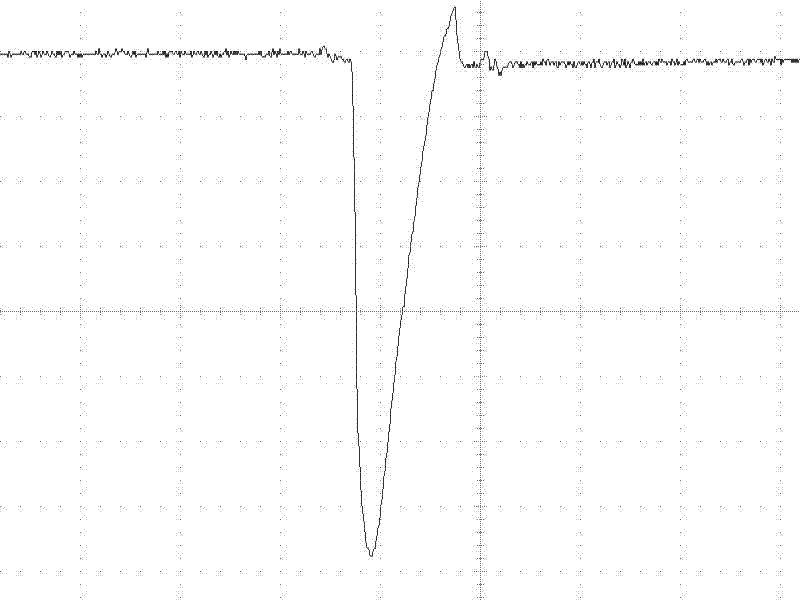

[0021] figure 1 It is a block diagram of the pulsed laser drive power module circuit structure based on the current switch of the avalanche transistor. It utilizes the characteristics of the current rising sharply when the carriers inside the transistor undergo an avalanche breakdown, and can obtain a rapid current rising edge on the laser diode. The DC source charges the energy storage capacitor 4 through the diode D to provide a voltage bias for the avalanche transistor 3, making it in a critical state. When the trigger signal arrives, the internal carriers of the 3 avalanche, and the capacitor 4 passes through the avalanche transistor 3 and quickly passes through the laser Diode 5 discharges. The optical pulse emitted by the laser diode is directly modulated by the electric pulse generated by the driving power supply. The rising edge of the current is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com