A production process of optimizing the secondary plastic package by widening the false cavity of the mold

A secondary plastic packaging and manufacturing process technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of product reliability and packaging dissatisfaction, increased feed inlet height, and high cost of plastic packaging materials. Achieve the effect of improving reliability, increasing the force area, and facilitating flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] A manufacturing process for optimizing a secondary plastic package by widening the false cavity of the mold, which is carried out according to the following steps:

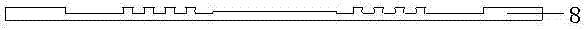

[0026] The first step, half-etching of the lead frame: Etch the lead frame 8 through mature gluing, exposure, development, electroplating and corrosion processes, etch the carrier, I / O pad pins on the frame, and determine the I / O soldering Pad pin size, pin spacing and their respective locations; as figure 1 shown;

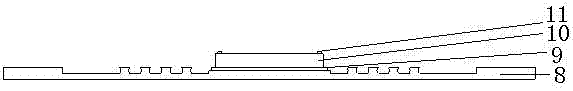

[0027] The second step, core loading: the chip 10 is bonded to the carrier of the lead frame 8 with the adhesive 9; figure 2 shown;

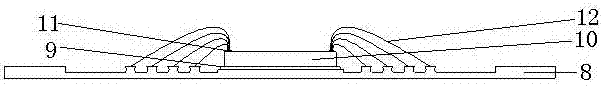

[0028] The third step, pressure welding: the solder joint 11 on the chip is connected with the pin of lead frame 8 with bonding wire 12; image 3 shown;

[0029] The fourth step, one-time plastic sealing: automatically transfer the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com