Transformer bushing

A technology of transformer bushings and bushings, which is applied to transformer/inductor parts, transformer/inductor coils/windings/connections, electrical components, etc. Leakage and other problems are prone to occur, achieving the effect of great practical and promotional value, convenient testing, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

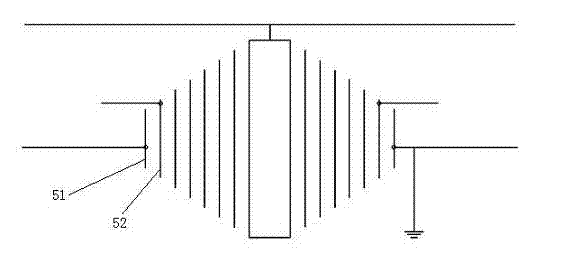

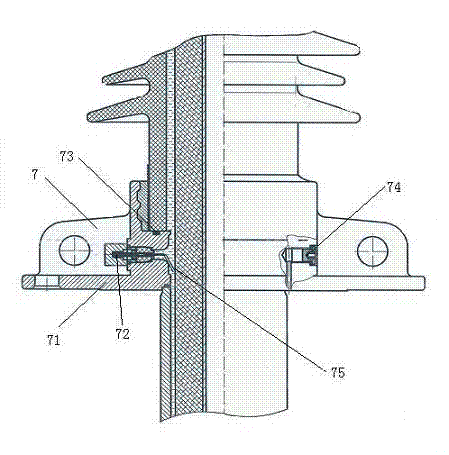

[0014] Refer to attached figure 1 , attached figure 2 , refer to attached image 3 , a transformer bushing of the present invention, which is composed of a conductive row 1, a general cap 2, a joint 3, an oil conservator 4, a bushing 5, a porcelain sleeve 6, a flange 7, a shielding bushing 8, an insulating cylinder 9, an equalizing The ball 10 and the conductive tube 11 are composed of a shielding sleeve 8 fixed on the flange 7; a pressure equalizing ball 10 is provided at the lower part of the shielding sleeve 8; a conductive tube 11 is inserted in the inner cavity of the shielding sleeve 8 A casing 5 is set on the periphery of the conductive pipe 11, and a porcelain casing 6 is set on the periphery of the casing 5. The insulating capacitor of the casing 5 is composed of an insulating medium and an electrode, and is formed by winding or dipping; The bushing 5 is an insulating capacitor provided with a plurality of lead-out taps, and the bushing 5 is an insulating capacitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com