Powder for sintering rare-earth permanent magnet

A rare-earth permanent magnet and powder technology, which is applied in the direction of magnetic objects, permanent magnets, magnetic materials, etc., can solve the problems that the magnetic properties of sintered rare-earth permanent magnets have not been greatly improved, and the cost of powder formulations cannot be reduced. Strengthen the effect of liquid phase assisted sintering, optimize the microscopic end, and improve the effect of encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

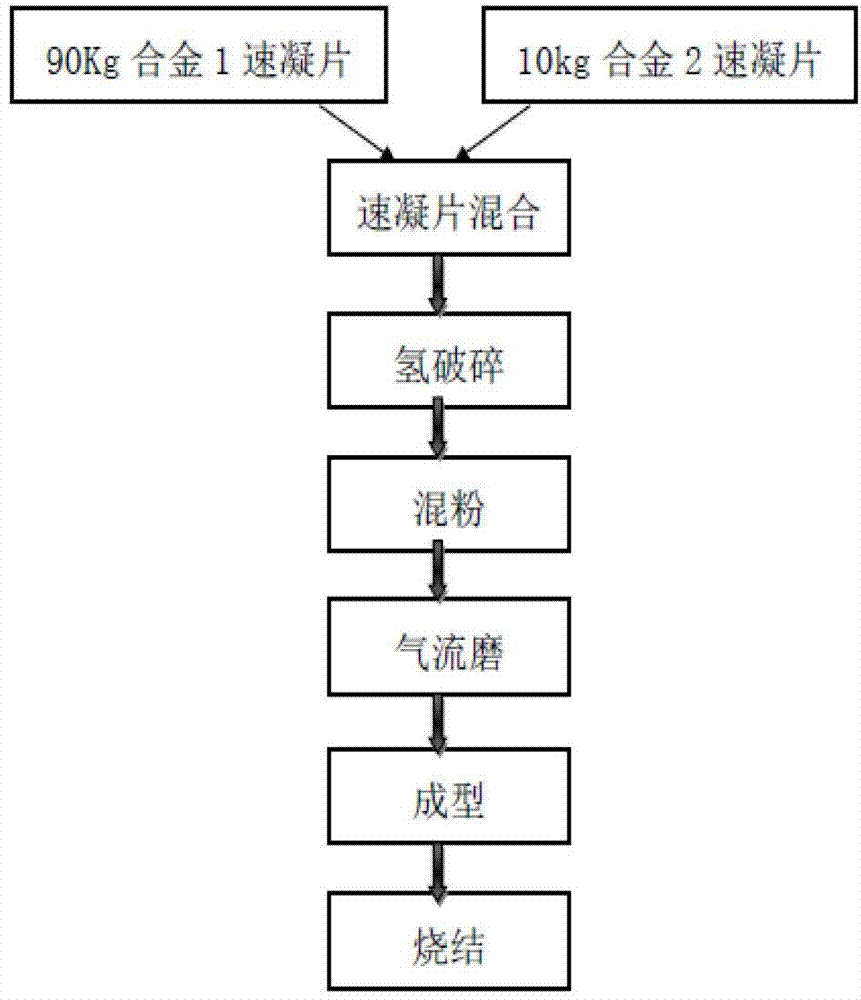

[0026] 1) The quick-setting sheets of two alloys made by the traditional quick-setting process are 90kg alloy 1 quick-setting sheet and 10kg alloy 2 quick-setting sheet;

[0027] 2) Mix the quick-setting sheets of the two alloys, and then place them in a hydrogen furnace for ventilation and crushing;

[0028] 3) Under the protection of inert gas, take out the alloy hydrogen powder, and carry out the jet mill process to make powder; obtain the powder for preparing sintered rare earth permanent magnet;

[0029] 4) Orientate the obtained powder in a magnetic field with a magnetic field of 1.2T, and carry out isostatic pressing;

[0030] 5) Send the formed blank into a sintering furnace under the protection of an inert gas for sintering, and perform heat treatment to obtain the final sintered rare earth permanent magnet.

[0031] figure 2 Shown is another embodiment of the invention:

[0032] 1) The quick-setting sheets of two alloys made by the traditional quick-setting proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com