Circuit protection device and its manufacturing method

A technology of circuit protection and manufacturing method, which is applied in the direction of resistors with positive temperature coefficients, resistance terminals/electrodes, etc., can solve the problems of affecting the effective use area of devices, shrinking the size of circuit protection devices, occupying functional areas, etc., and achieving improvement Effective use of area, small device size, and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

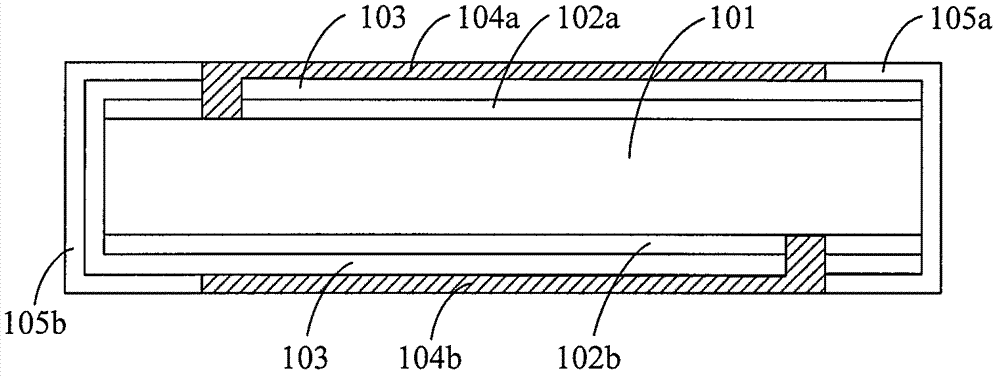

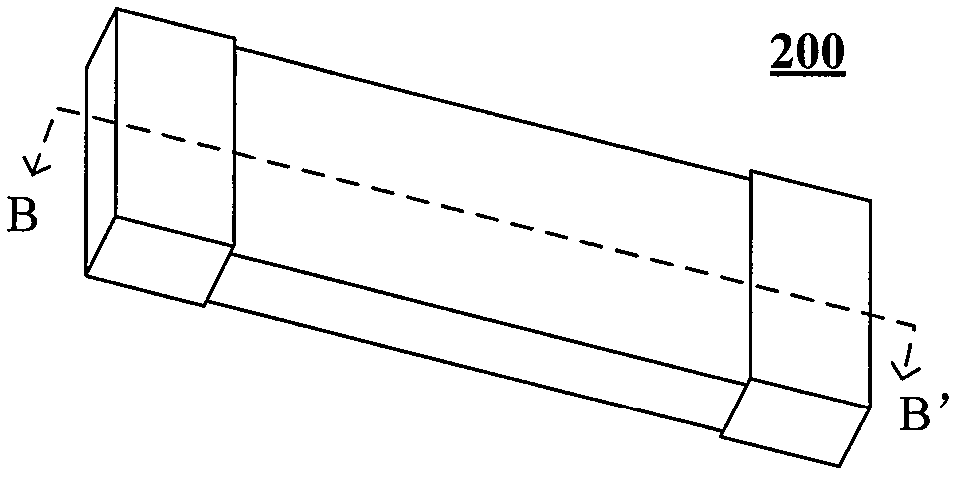

[0017] Figure 2a and Figure 2b A circuit protection device 200 according to a first embodiment of the present invention is shown. in, Figure 2a is a schematic perspective view of the circuit protection device 200, Figure 2b is along Figure 2a Schematic cross-sectional view in the direction of BB'. Next, combine Figure 2a and Figure 2b The circuit protection device 200 of the first embodiment of the present invention will be described.

[0018] Such as Figure 2a and Figure 2b As shown, the circuit protection device 200 includes:

[0019] A heat-sensitive material layer 201 with a positive temperature coefficient, the heat-sensitive material layer 201 has an opposite first surface 202 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com