A pretreatment device for carbon and hydrogen isotope analysis of gas and liquid inclusions in minerals

A pretreatment device, hydrogen isotope technology, applied in the preparation of test samples, etc., can solve the problems of the system vacuum degree being difficult to reach the standard, affecting the accuracy of the analysis results, wasting time, etc., achieving the vacuum degree quickly reaching the standard, and improving the efficiency of sample preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

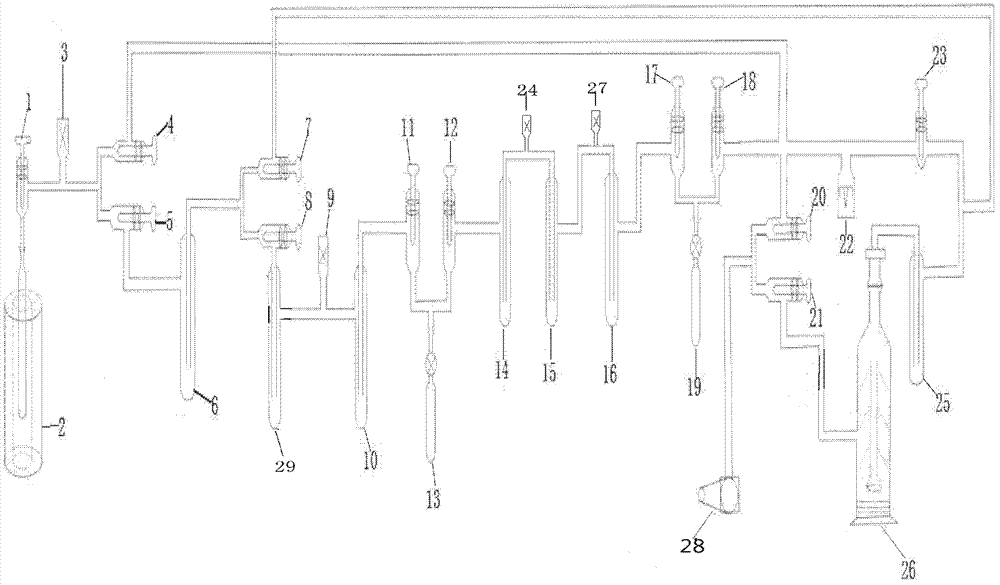

[0021] The invention includes a high-temperature burst system, an oxidation system, a separation and purification system, a carbon dioxide collection pipe, a reduction system, a hydrogen collection pipe and a vacuum system which are sequentially sealed and connected.

[0022] The high-temperature burst system includes a quartz pyrolysis tube 2 and a first vacuum gauge 3 that are hermetically connected through a twelfth valve 1 . The first vacuum gauge 3 preferably adopts the ZJ-2 vacuum gauge of the Department of Electronics of Peking University, with a range of 1 to 10 5 Pa, used to monitor the bursting degree of minerals. Quartz pyrolysis tube 2 has a melting point of 1300° C., a length of 20 cm, an inner diameter of 1.5 cm, and an outer diameter of 1.8 cm. There is a vacuum grinding hole at the upper end to realize sealing.

[0023] The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com