Composite oil cylinder and hydraulic machine with double action function with composite oil cylinder

A composite oil cylinder and oil cylinder technology, applied in the field of hydraulic machines, can solve the problems of increasing the tonnage and cost of hydraulic machinery, the influence of pressure tonnage, and poor dimensional accuracy of parts, and achieve the effects of simplifying design and manufacturing, reducing manufacturing costs and reducing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the content of the present invention more clearly, further description will be made below in conjunction with the accompanying drawings and specific embodiments:

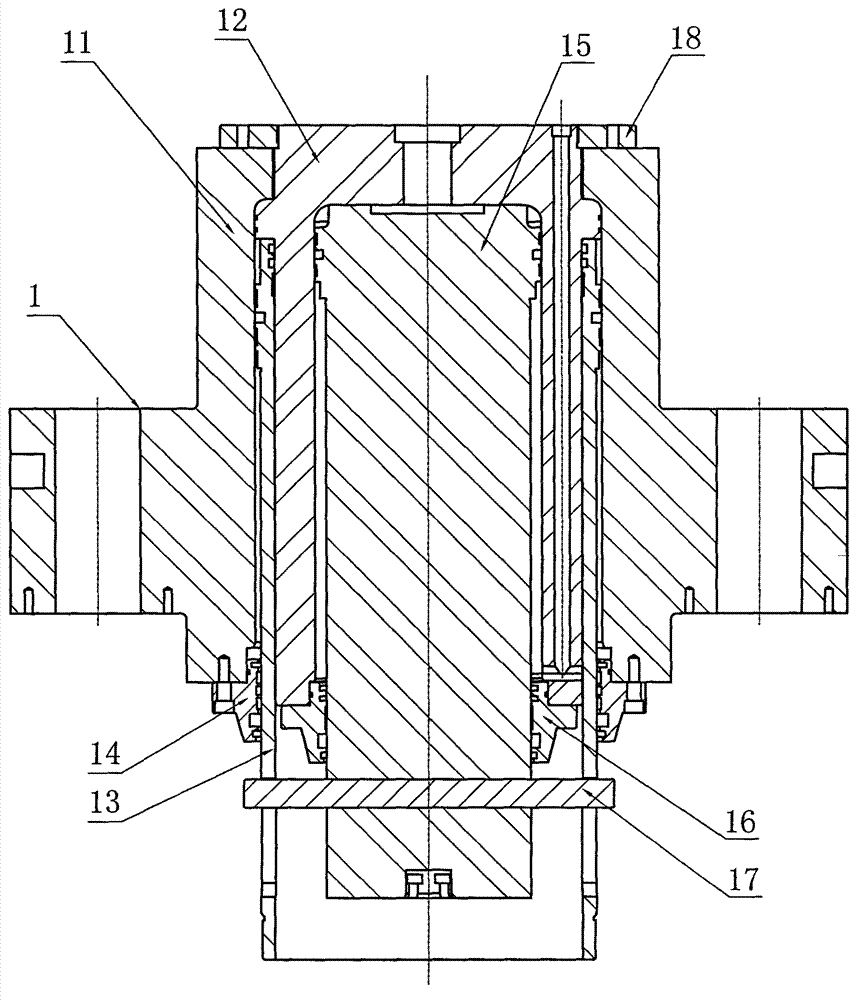

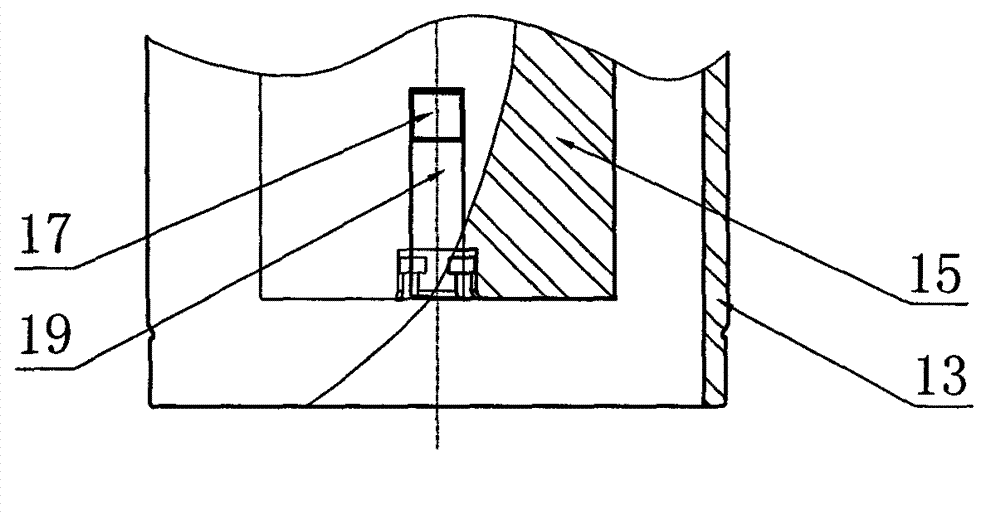

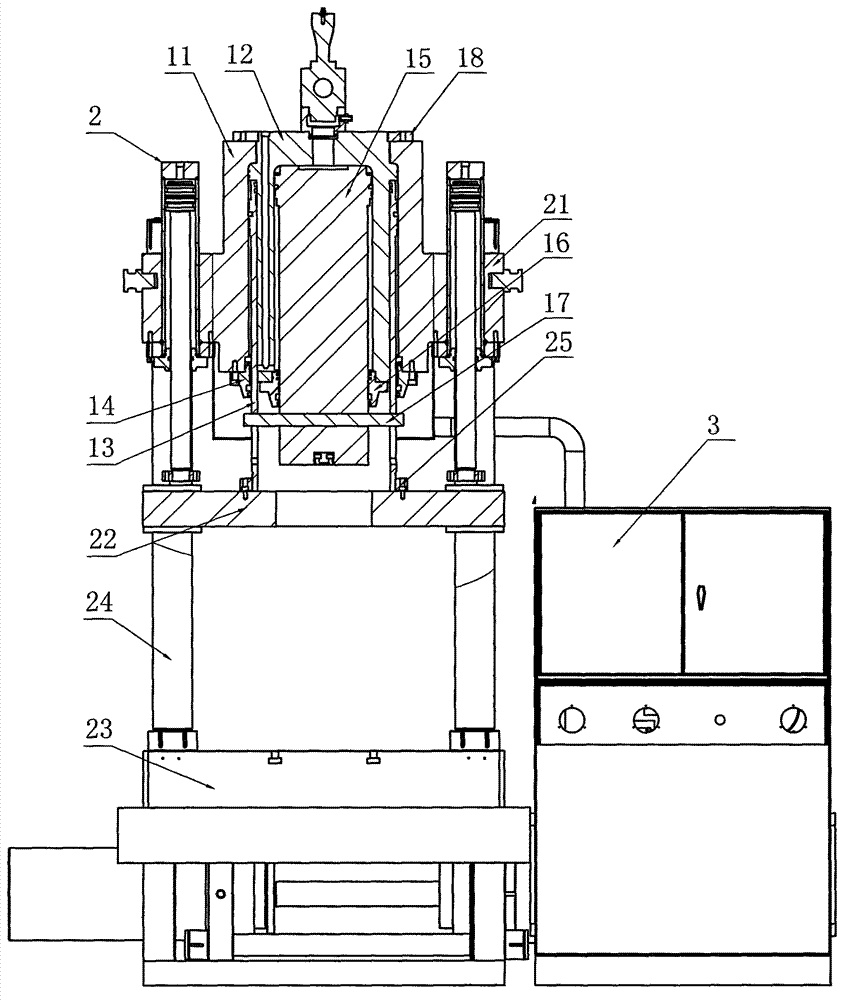

[0026] like figure 1 and figure 2 As shown, a composite oil cylinder 1 includes a primary cylinder system and a secondary cylinder system. The primary cylinder system includes the outer circle of a primary cylinder body 11, a secondary cylinder body 12, a primary cylinder piston rod 13 and a primary cylinder The guide sleeve 14 is composed of the first-stage cylinder body 11, the outer circle of the second-stage cylinder body 12, the first-stage cylinder piston rod 13 and the first-stage cylinder guide sleeve 14 to form a closed load-transmitting hydromechanical structural system, that is, an annular oil cylinder system The secondary oil cylinder system comprises the inner hole of the secondary cylinder body 12, the secondary cylinder piston rod 15 and the secondary cylinder guide sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com