Device and method for utilizing plastic manufacturing technique waste gas and low temperature exhaust heat to generate electricity

A production process and low-temperature waste heat technology, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of wasting energy, not being able to be effectively used, polluting the environment, etc., achieve high power generation efficiency, and solve the low-temperature waste heat recovery utilization rate low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The device and method of the present invention will be further described below in conjunction with the accompanying drawings.

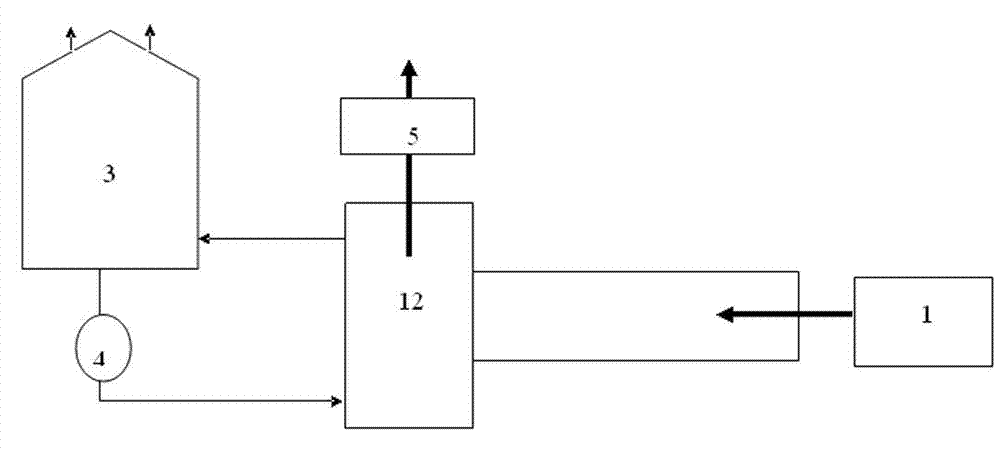

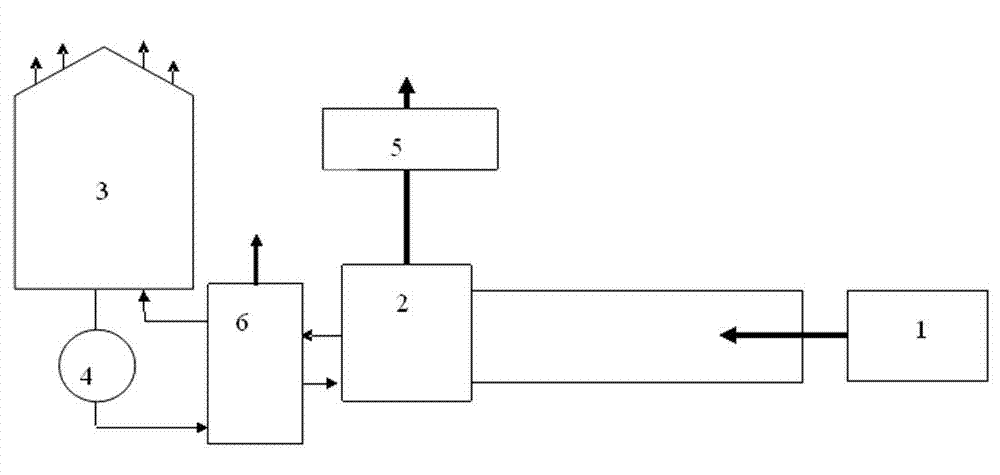

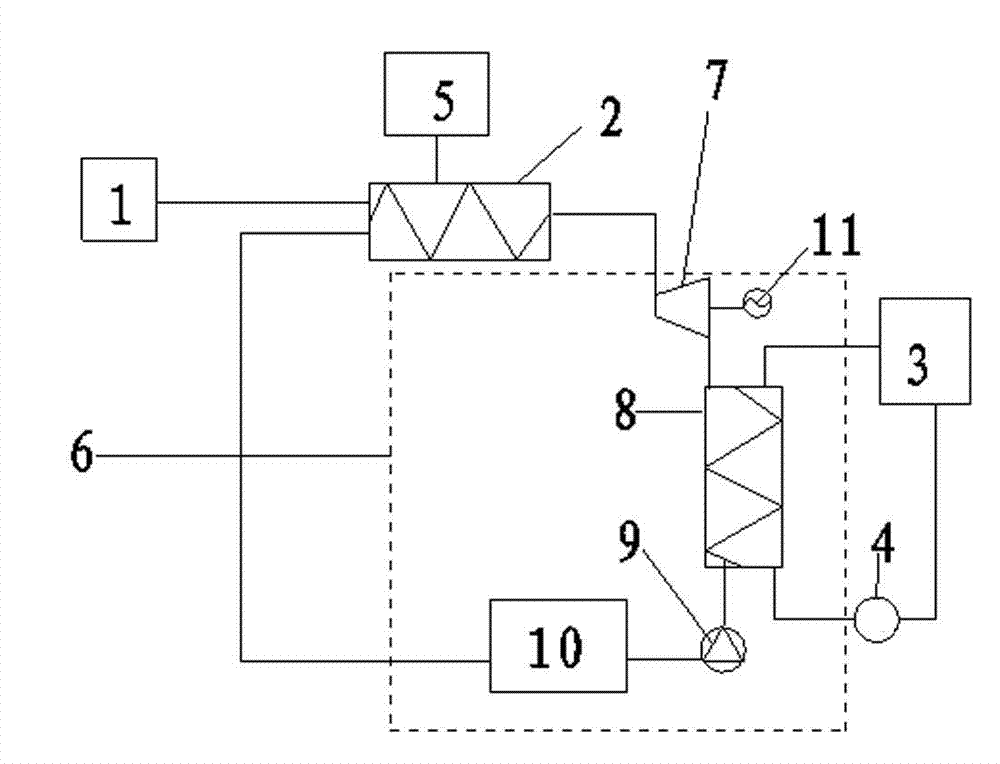

[0018] Such as figure 2 , 3 The shown device for generating electricity by utilizing low-temperature waste heat of exhaust gas from a plastic production process includes an exhaust gas generating device 1, an evaporator 2, a low-temperature generator set 6, and a cooling water tower 3 connected in sequence through pipelines; the low-temperature generator set 6 is respectively connected through pipelines It is connected with the evaporator 2 and the cooling water tower 3 to form a circuit; the low-temperature generating set 6 includes a twin-screw expander 7, a condenser 8, a cooling water pump 4, a high-pressure working medium pump 9, a preheater 10, and a generator 11, wherein The output shaft of the twin-screw expander 7 is connected to the generator 11, the input end is connected to an output end of the evaporator 2, the output end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com