Method for extracting xylose by strong-flavor solid white wine vinasse

A solid-state liquor, strong-flavor technology, which is applied in the field of industrial waste resource utilization, can solve the problems such as the extraction of xylose that has not yet been retrieved, achieves good promotion and application prospects, realizes waste utilization, and has the effects of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

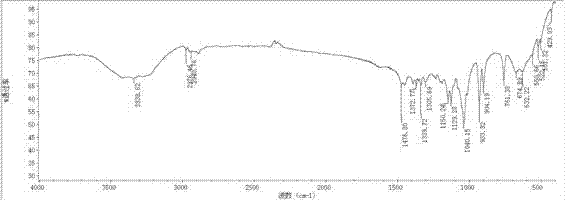

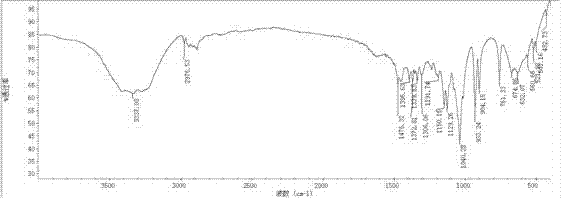

Image

Examples

Embodiment 1

[0035] 1) Pretreatment of distiller's grains

[0036] Take 1000g of fresh distiller's grains, dry or dry them to get 389g of distiller's grains as a dry basis, sieve to remove impurities such as sand and soil, add water and boil for 1 hour, and the mass ratio of solid to liquid is 1:10. After boiling, filter, take the filter residue, dry and set aside.

[0037] 2) Acid hydrolysis of distiller's grains

[0038] Take the dried distiller's grains, add 2% dilute sulfuric acid, the mass ratio of solid to liquid is 1:10, and acidify at 120 ° C for 2 hours. After acidolysis, filter, wash the filter residue with distilled water, and collect it together with the filtrate for later use. Obtain 2700ml acid hydrolyzed solution, measure its solid content to be 3%.

[0039] 3) Impurity removal and purification of acid hydrolysis solution

[0040] Add CaCO to the hydrolyzate in a water bath at 80°C 3 , keep stirring, neutralize to pH2.5-3.0, continue stirring, keep warm for 1h, filter, ...

Embodiment 2

[0044] 1) Pretreatment of distiller's grains

[0045] Take 1000g of fresh distiller's grains and dry them to obtain 395g of distiller's grains on a dry basis. After sieving to remove impurities such as sand and soil, add water and boil for 1 hour. The mass ratio of solid to liquid is 1:10. After boiling, filter, take the filter residue, dry and set aside.

[0046] 2) Acid hydrolysis of distiller's grains

[0047] Take the dried distiller's grains, add 2% dilute sulfuric acid, the mass ratio of solid to liquid is 1:10, and acidify at 120 ° C for 2 hours. After acidolysis, filter, wash the filter residue with distilled water, and collect it together with the filtrate for later use. Obtain 2750ml acid hydrolyzate, measure its solid content as 3.1%.

[0048] 3) Impurity removal and purification of acid hydrolysis solution

[0049] Add CaCO to the hydrolyzate in a water bath at 80°C 3 , keep stirring, neutralize to pH3.0-3.5, continue stirring, keep warm for 1h, filter, wash, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com