Culture medium for improving chitinase produced by streptomyces sampsonii KJ40 and chitinase bacteria-containing preparation and application

A technology of Streptomyces mulberry and chitinase, applied in the application, fungicides, enzymes and other directions, can solve the problems of accelerating product synthesis speed, affecting product synthesis, increasing temperature, etc., and achieving the effect of preventing poplar purple root disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

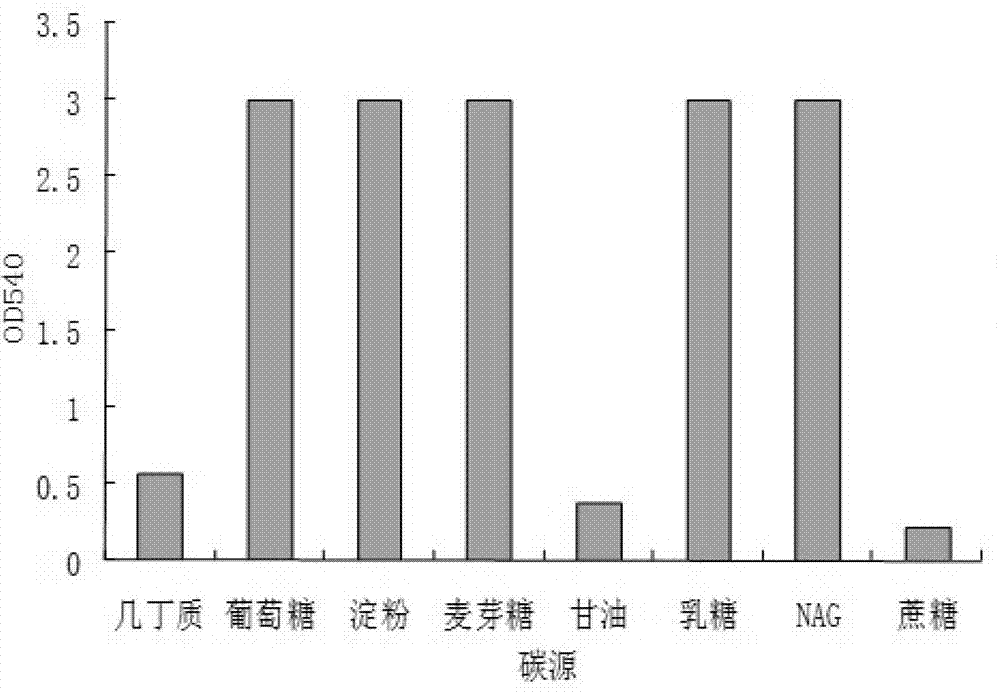

[0020] On the enzyme-producing basal medium, by adding carbon source, nitrogen source, and other single-factor experiments, the composition of the medium was determined, and an orthogonal experiment with 4 factors and 3 levels was designed to obtain the best enzyme-producing strain under the influence of 4 factors. The ratio is: colloidal chitin (solubility of colloidal chitin aqueous solution is 2%, w / V) 100ml / L, soybean cake powder 0.4%, K 2 HPO 4 1.0(g / L), KH 2 PO 4 0.6 (g / L). Among them, the content of nitrogen source has the greatest impact on enzyme production, followed by K 2 HPO 4 content, compared to substrate concentration and KH 2 PO 4 content had little effect on enzyme production.

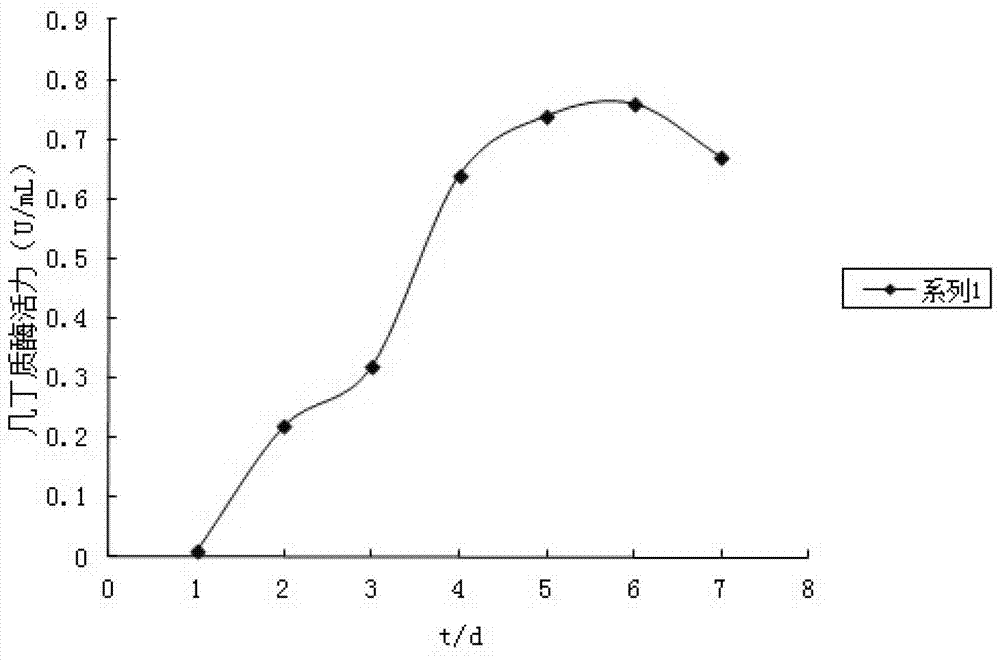

[0021] 1.1 The relationship between culture time and enzyme production

[0022] Enzyme-producing basal medium (colloidal chitin 200ml, K 2 HPO 4 0.7g, KH 2 PO 4 0.3g, MgSO 4 ·7H 2 O0.5g, FeSO 4 ·7H 2 O0.01g, ZnSO 4 0.001g, distilled water 1000ml, pH7.0) as the initial ...

Embodiment 2

[0049] (1) Streptomyces sansoni seed production

[0050] 1. Strain activation: Transfer Streptomyces sanneri KJ40 slant strain to the plate (glucose 10g, peptone 5g, NaCl 5g, beef extract 5g, agar 20g, distilled water 1000ml, pH7.0-7.2), and culture at 25°C for 4 days.

[0051] 2. Preparation of Streptomyces sanneri seed solution: Prepare the prepared culture solution (colloidal chitin 200ml, K 2 HPO 4 0.7g, KH 2 PO 4 0.3g, MgSO 4 ·7H 2 O0.5g, FeSO 4 ·7H 2 O0.01g, ZnSO 4 0.001g, distilled water 1000ml, pH7.0) into 100ml Erlenmeyer flasks, 20ml per bottle, sterilized at 121°C for 30min, after cooling, add 1m concentration of 107 / ml spore suspension (Sanella bacteria) to each bottle, Then place it on a constant temperature shaker, and culture it at 26° C. with shaking at 140 r / min for 36 hours.

[0052] (2) Chitinase production and enzyme activity detection

[0053] 1. The best formula for producing enzymes: colloidal chitin (solubility of colloidal chitin aqueous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com