Seismic isolation rubber bearing protective rubber composite with good anti-aging performance

A technology of rubber composition and shock-absorbing rubber, which is applied in the field of rubber products, can solve the problems of environmental protection producers' health, etc., and achieve the effect of improving environmental protection performance, service life, high temperature resistance and related physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1. The rubber composition of the present embodiment is made up of the following components by weight:

[0041] 50 parts of natural rubber,

[0042] 50 parts of EPDM rubber,

[0043] High wear-resistant furnace black N330 35 parts,

[0045] 1.8 parts of stearic acid,

[0046] Insoluble sulfur 1.0 part,

[0047] Accelerator CZ 1.9 parts,

[0048] Anti-aging agent 616 2.0 parts,

[0049] Anti-aging agent phosphite 2.0 parts,

[0050] Softener tricresyl phosphate 8 parts,

[0051] 5 parts of softener paraffin oil No. 100,

[0052] Softener coumarone 4 servings

[0053] 2 parts of coupling agent Si-69,

[0054] Anti-reversion agent wk-901 0.5 parts.

[0055] Weigh each material according to the above formula ratio, first masticate the natural rubber on the open mill, then add EPDM rubber and then masticate, and the roll distance is controlled at 3-5mm. After the raw rubber is wrapped, the triangular bag is made until the s...

Embodiment 2

[0073] Example 2: The rubber composition is composed of the following components in parts by weight:

[0074] 55 parts of natural rubber,

[0075] 45 parts of EPDM rubber,

[0076] 40 parts of high wear-resistant furnace black N330,

[0077] 4.5 parts of zinc oxide,

[0078] 2.0 parts of stearic acid,

[0079] 0.8 parts of insoluble sulfur,

[0080] Accelerator CZ 2.2 parts,

[0081] Anti-aging agent 616 1.0 parts,

[0082] Anti-aging agent phosphite 1.0 parts,

[0083] Softener tricresyl phosphate 5 parts,

[0084] 5 parts of softener paraffin oil No. 100,

[0085] Softener coumarone 2 parts

[0086] 1 part of coupling agent Si-69,

[0087] Anti-reversion agent wk-901 0.2 parts.

[0088] The manufacturing process is the same as that of Example 1.

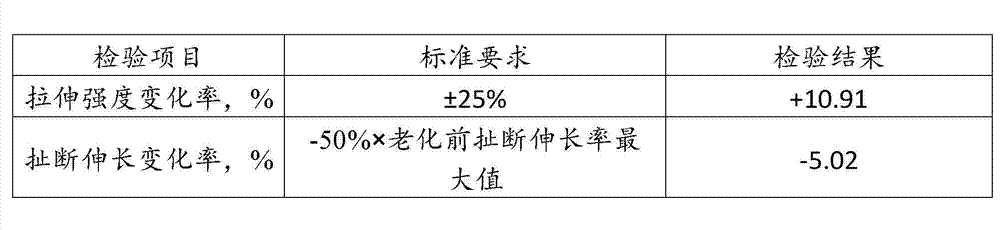

[0089] The physical properties are tested according to the national standards and industry standards. The anti-aging performance of the rubber in this example can meet the requirements of the design life of the structur...

Embodiment 3

[0090] Example 3. The rubber composition consists of the following components in parts by weight:

[0091] 60 parts of natural rubber,

[0092] 40 parts of EPDM rubber,

[0093] High wear-resistant furnace black N330 45 parts,

[0094] 8 parts of zinc oxide,

[0095] 1.5 parts stearic acid,

[0096] 1.5 parts of insoluble sulfur,

[0097] Accelerator CZ 3.0 parts,

[0098] Anti-aging agent 616 1.2 parts,

[0099] Anti-aging agent phosphite 1.6 parts,

[0100] Softener tricresyl phosphate 9 parts,

[0101] 7 parts of softener paraffin oil No. 100,

[0102] Softener coumarone 5 parts

[0103] 1 part of coupling agent Si-69,

[0104] Anti-reversion agent wk-901 0.5 parts.

[0105] The manufacturing process is the same as that of Example 1.

[0106] The physical properties are tested according to the national standards and industry standards. The anti-aging performance of the rubber in this example can meet the requirements of the design life of the structure, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| 300% modulus stress | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com