Automatic goods receiving system

An automatic and cargo technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of heavy workload and easy errors for the staff, and achieve the effects of reducing energy consumption, improving safety, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

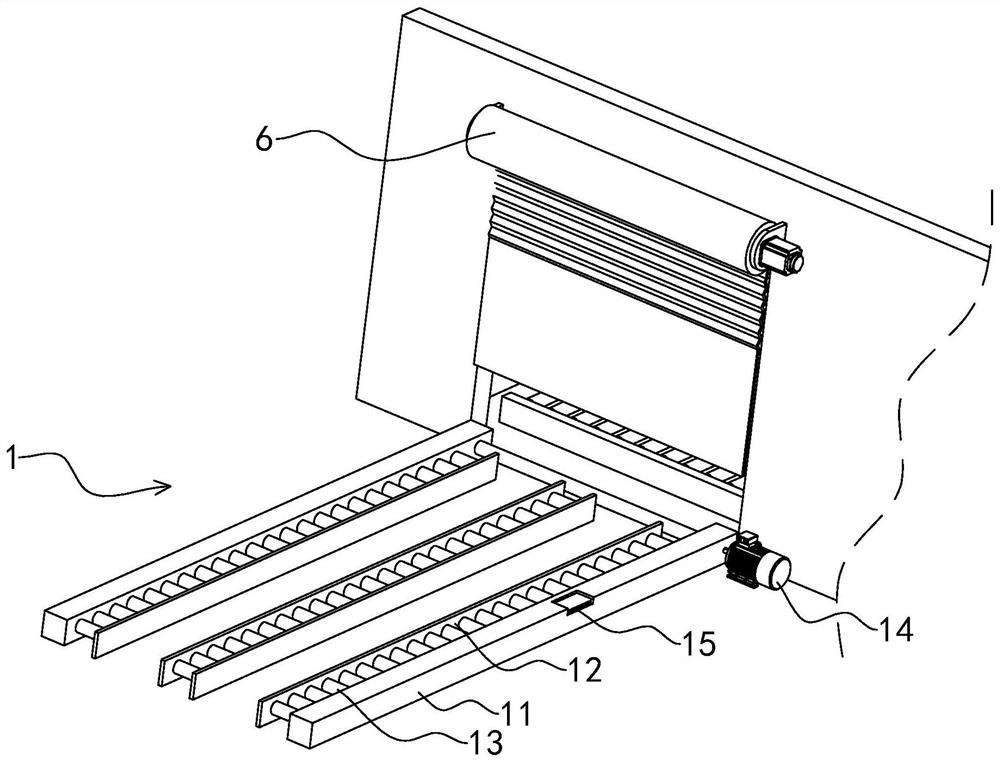

[0036] The embodiment of the present application discloses an automatic goods receiving system.

[0037] refer to figure 1 , an automatic goods receiving system includes an incoming goods device 1 for docking with trucks to accept materials and input them into the warehouse, and a transfer device 2 for supporting and placing goods on the outside of the warehouse. Room 5, the discharge end of the transition chamber 5 is provided with a conveying device 3 for conveying goods, and the side of the transition chamber 5 close to the conveying device 3 and the incoming device 1 is provided with a fast rolling curtain 6, and the fast rolling curtain 6 is set not to be opened at the same time .

[0038] refer to figure 2 , the transfer device 2 includes three supporting mechanisms 23 arranged in parallel, the supporting mechanism 23 includes a seat body 231, the bottom surface of the seat body 231 is provided with a groove 232 arranged along the walking direction of the transfer dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com