Device And Method For Sterilisation Packaging Items

A packaging and fixing mechanism technology, which is applied in the directions of packaging machines, packaging, disinfection, etc., can solve the problems of harmful users and complicated shielding equipment, and achieve the effect of simplifying mechanical technology and omitting the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

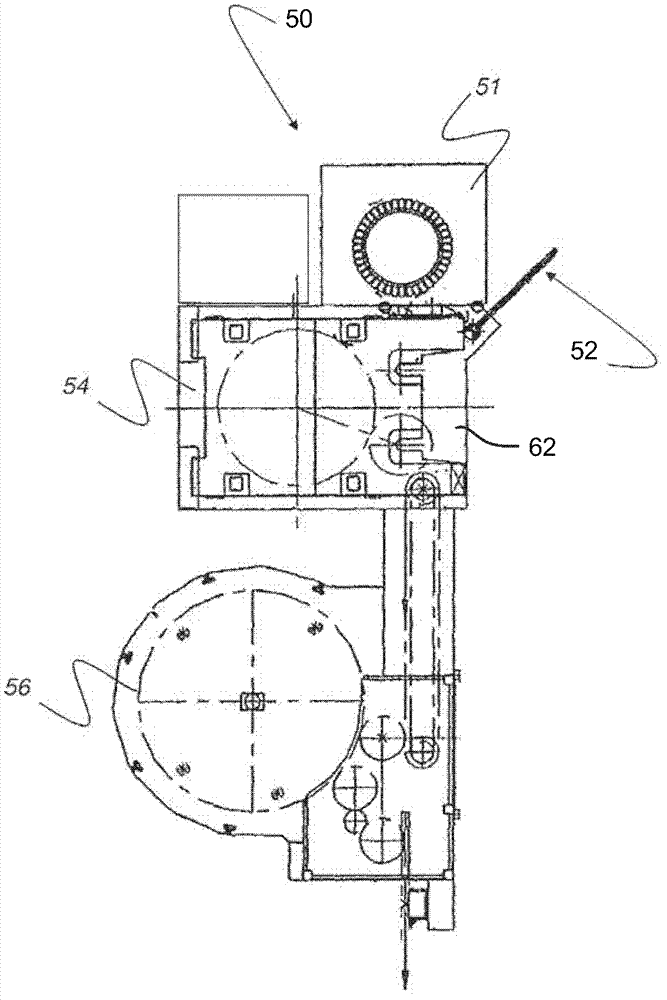

[0057] figure 1 Shown is a plant 50 for processing containers. In this case, reference numeral 52 designates a supply device that transfers the plastics material pre-forms to a heating device or furnace 51 . In this case, the heating device 51 can be a microwave oven in which the container or the plastics material pre-form, respectively, is conveyed along a circulation path and heated in a resonator, respectively. However, it is also possible for the device to have an infrared (IR) heating element, which can also be designed in the form of a heating chamber for separate heating of the plastics material pre-forms. The heating device adjoins a stretch blow molding machine 54 in which the plastics material pre-forms are heated to form plastics material containers. Afterwards, the filling machine 56 fills the containers and the containers are transported away.

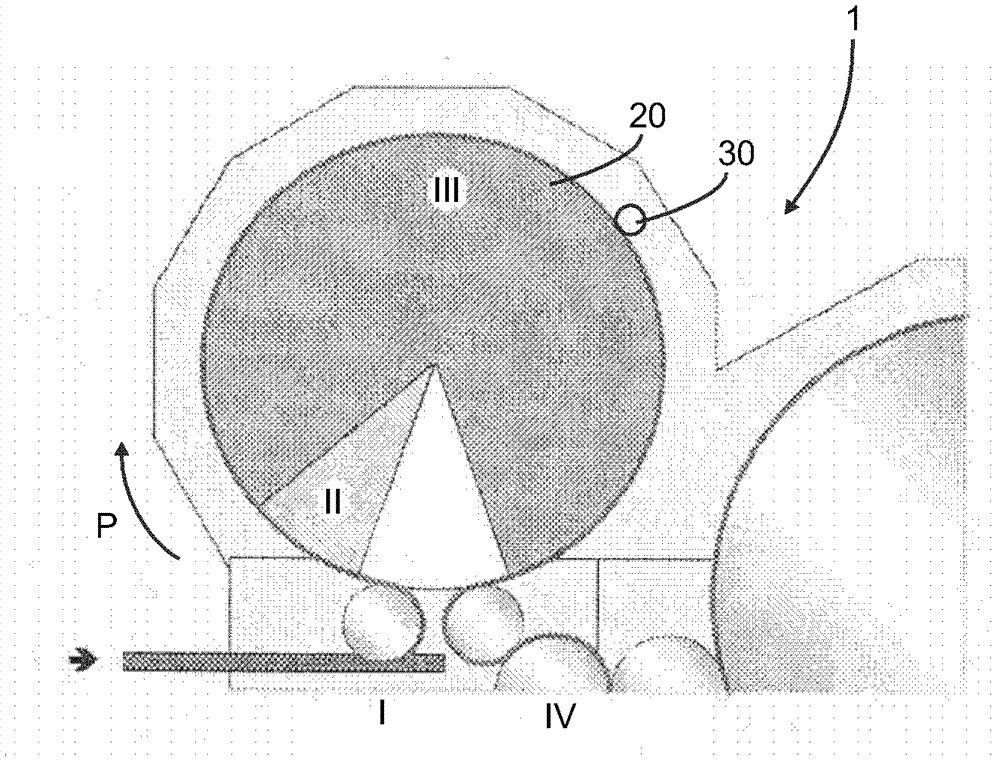

[0058]As mentioned above, preferably, the device 1 according to the invention is used for sterilizing plastics materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com