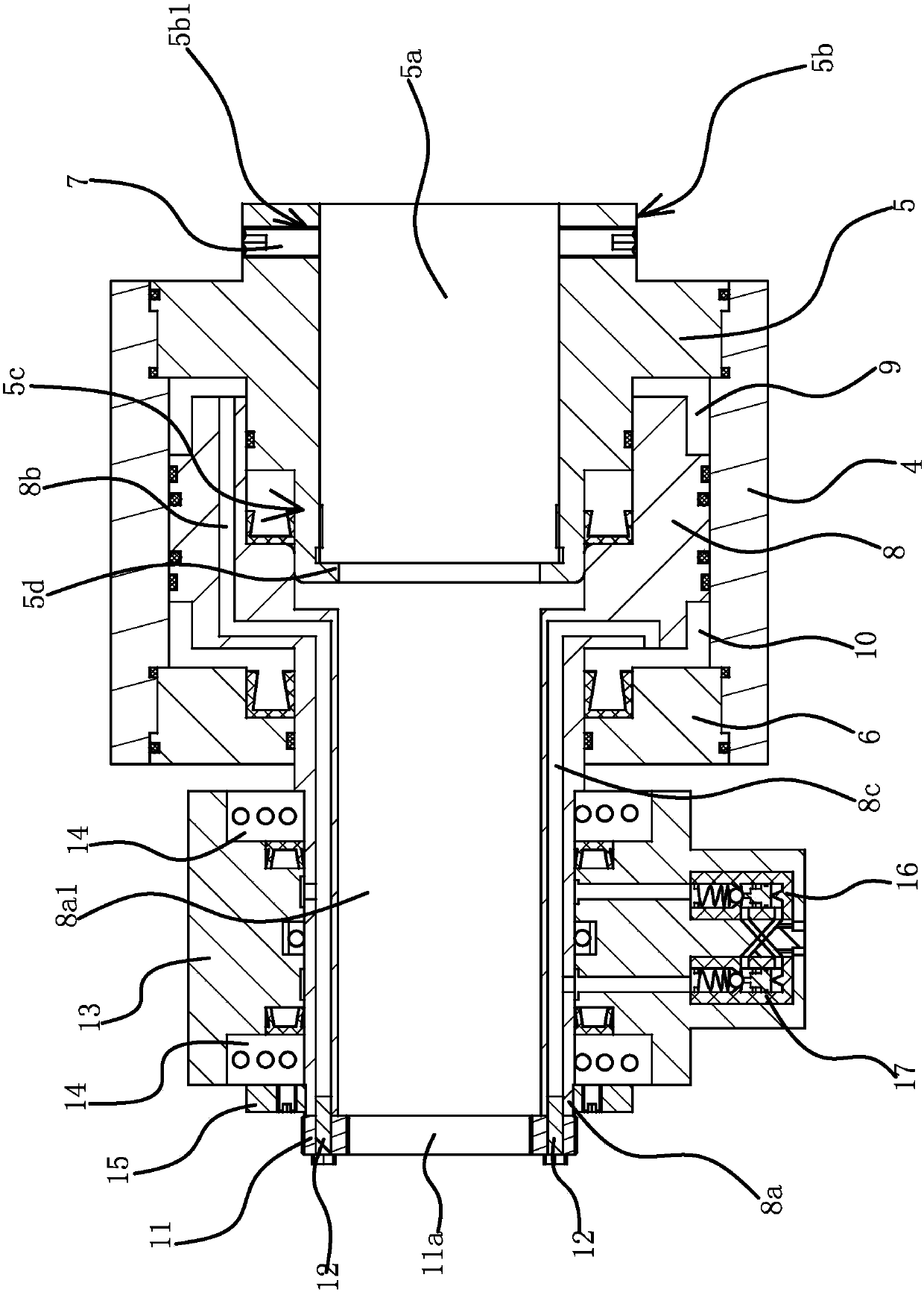

Rotary oil cylinder for lathe spindle box

A technology of a lathe spindle and a rotary oil cylinder, applied in the field of machinery, can solve the problems of inconvenient disassembly, inconvenient dismantling of a pipe and a piston, and inability to pull a pipe and a piston to rotate and dismantle, etc., and achieves the effect of improving the convenience of disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

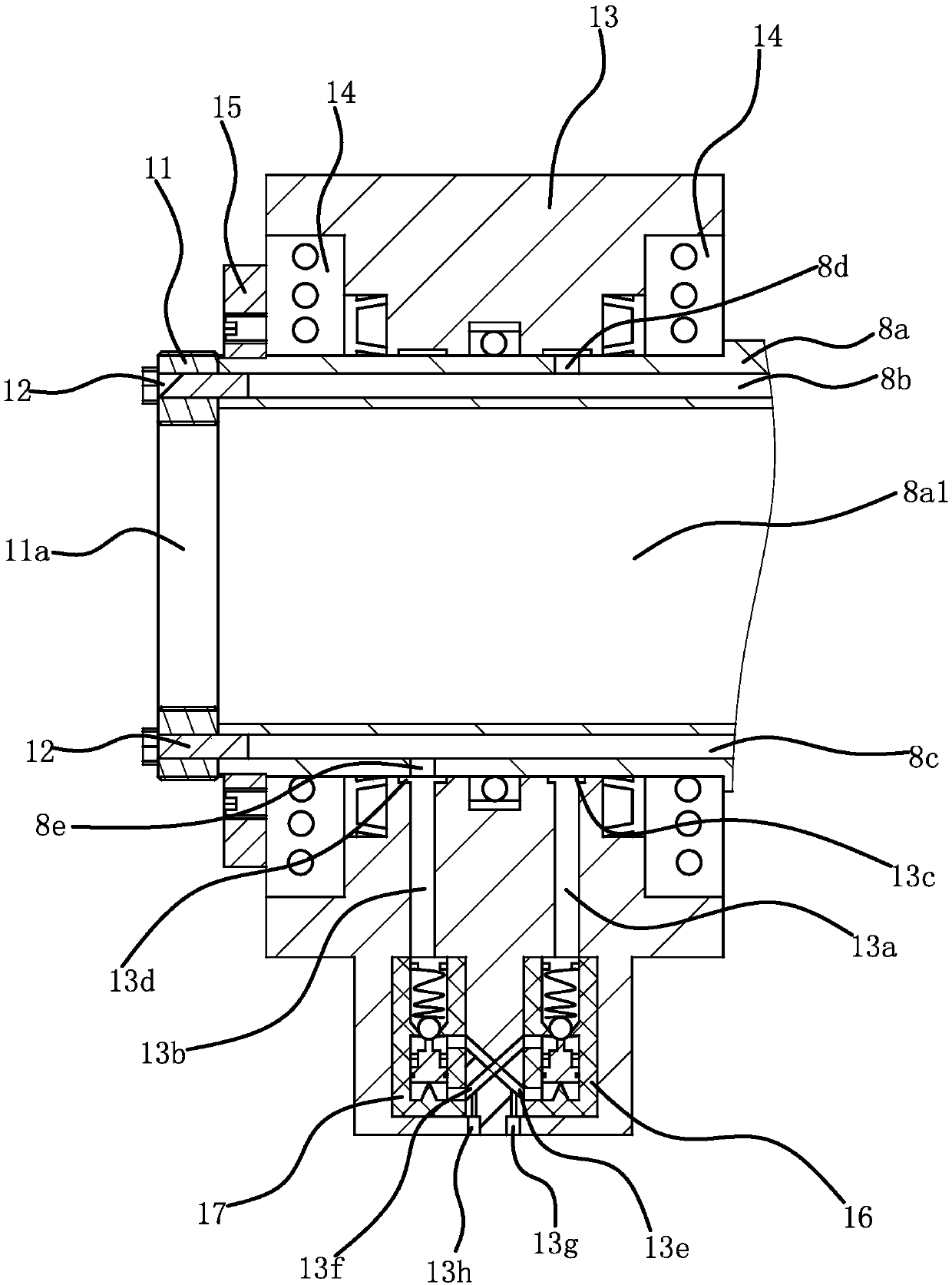

Embodiment 2

[0069] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in this embodiment, the mounting plate 11 is provided with a fixing hole that enables the mounting plate 11 to be screwed to the outside of the end of the mating portion 8a. The hole is connected with the mounting hole 11a and the fixing hole is coaxial with the mounting hole 11a. The fixing hole is opened on the outer end face of the mounting plate 11, and the mounting hole 11a is opened on the inner end face of the mounting plate 11, and the aperture of the fixing hole is larger than the mounting plate. The diameter of the hole 11a.

[0070] The mounting plate 11 is provided with a fixed hole with an aperture larger than the aperture of the mounting hole 11a. When the mounting plate 11 is used to connect the fitting portion 8a of the drawing tube 2 and the piston 8, one end of the mounting plate 11 provided with the fixing hole is passed through the dra...

Embodiment 3

[0072] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, one end of the mounting plate 11 is provided with a fixing hole that enables the mounting plate 11 to be screwed to the outside of the end of the mating portion 8a , the other end of the mounting plate 11 is provided with a relief hole that can be penetrated by the pull pipe 2 of the lathe headstock, the relief hole is connected with the fixing hole and is coaxial with the fixing hole, and the aperture of the fixing hole is larger than the letting hole. As for the diameter of the bit hole, the side of the mounting plate 11 is penetratingly provided with a fastening hole laterally communicating with the setback hole, and the fastening hole is internally threaded with a fastening screw.

[0073] When assembling, the mounting plate 11 is sleeved on the pull tube 2 through the relief hole, and then the mounting plate 11 is rotated, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com