Scrap copper wire material separation treatment system and corresponding separation process

A technology for separation treatment and copper wire, applied in the field of waste copper wire material separation treatment system, can solve the problems of environmental pollution, short treatment process, waste of resources, etc., and achieve the effect of saving human resources, reasonable process route, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

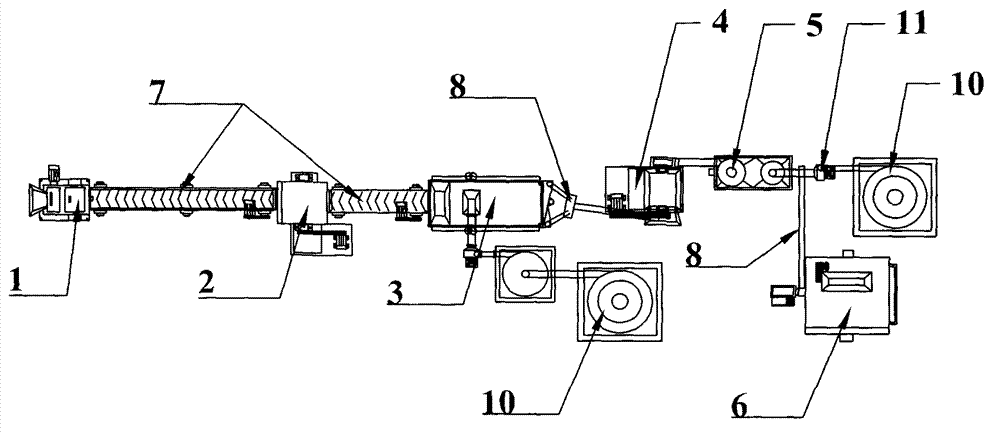

[0027] Implementation mode one: if figure 1 , 2 As shown, the waste copper wire material separation treatment system includes a cutting machine 1, a crusher 2, a wind pressure vibration separator 3, a pulverizer 4, a specific gravity separator 5 and a high-voltage electrostatic separator 6; Between the crusher 2, between the crusher 2 and the wind pressure vibration separator 3, a magnetic separation conveyor 7 is provided, between the wind pressure vibration separator 3 and the pulverizer 4, and between the specific gravity separator 5 and the high-voltage electrostatic separation Screw conveyors 8 are provided between the devices 6, and bucket elevators 9 are provided on the high-voltage electrostatic separator 6.

[0028] Described air pressure vibration separator 3 and specific gravity separator 5 are all provided with dedusting device 10, and this dedusting device 10 is three-stage dedusting device, and it comprises cyclone dedusting mechanism, cloth bag dedusting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com