Catalyst for the direct preparation of ethanol from acetic acid, its preparation method and use

A catalyst and acetic acid technology, applied in the field of catalytic chemistry, can solve the problems of high requirements for reaction temperature and reaction pressure, high catalyst cost, harsh conditions, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

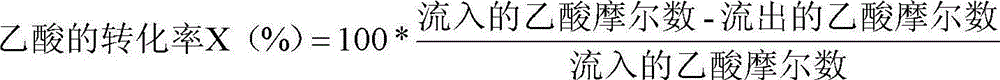

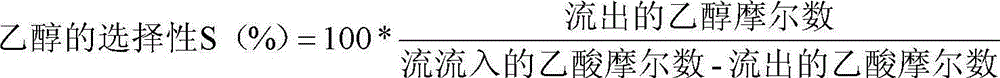

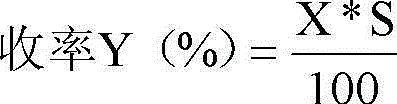

Image

Examples

Embodiment A

[0048] Preparation of Pt0.01%-Sn0.01% / SiO 2 Catalyst (no non-precious metal components, for comparison)

[0049] Mix the aqueous solution (0.67ml) of chloroplatinic acid (0.027g) and the dilute nitric acid solution (1ml) of tin oxalate (0.017g) and add water to form a 72.6ml impregnation solution, add it to 100g of silicon dioxide, and add it as you go. After stirring, the obtained material was dried in an oven gradually heated to 110° C. for 2 hours, and then calcined in a muffle furnace at 500° C. (heating rate, 2° C. / min) for 4 hours to obtain a catalyst sample.

Embodiment B

[0051] Preparation of Pt0.09%-Sn0.09% / SiO 2 Catalyst (no non-precious metal components, for comparison)

[0052] Mix an aqueous solution (6.03ml) of chloroplatinic acid (0.243g) and a dilute nitric acid solution (1ml) of tin oxalate (0.153g) and add water to form a 72.6ml impregnating solution, which is added to 100g of silicon dioxide and added while adding After stirring, the obtained material was dried in an oven gradually heated to 120° C. for 3 hours, and then calcined in a muffle furnace at 500° C. (heating rate, 2° C. / min) for 4 hours to obtain a catalyst sample.

Embodiment C

[0054] Preparation of Pt0.09%-Sn0.09%-Ni15% / SiO 2 Catalyst (catalyst according to the invention)

[0055] Mix an aqueous solution (6.03ml) of chloroplatinic acid (0.243g), a dilute nitric acid solution (1ml) of tin oxalate (0.153g) and an aqueous solution (50ml) of nickel nitrate (74.17g) and add water to form a 72.6ml impregnation solution , added to 100g of silicon dioxide, and stirred while adding, the obtained material was dried in an oven gradually heated to 110°C for 2 hours, and then roasted in a muffle furnace at 600°C (heating rate, 2°C / min) for 3 hours, the catalyst sample was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com