Imatinib mesylate tablet cores, coated tablets, and preparation method thereof

A technology of imatinib mesylate and coated tablets is applied in the field of medicine to achieve the effects of improving drying rate, uniform content and improving compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

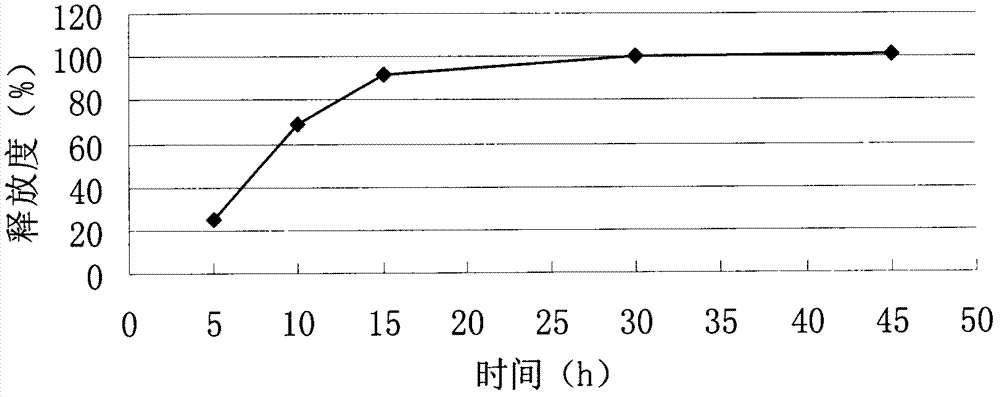

Embodiment 1

[0056] Example 1: Tablet formulation (50 mg tablet)

[0057] 1.1 The formula of imatinib mesylate tablet core in the present embodiment is as shown in Table 1.

[0058] The imatinib mesylate tablet core formula of table 1 embodiment 1 (making 10000 altogether)

[0059]

[0060] 1.2 Prepare the imatinib mesylate tablet core of the above-mentioned formula, carry out according to the following steps:

[0061] 1.2.1 The raw material is air-pulverized, and the particle size is less than 20um.

[0062] 1.2.2 Mix imatinib mesylate, microcrystalline cellulose and sodium carboxymethyl starch evenly, add polyvinylpyrrolidone K30 solution with a concentration of 12% by mass percentage, carry out rapid stirring and granulation, and obtain soft material Fluidized bed drying under the condition of wind temperature 65 ℃.

[0063] 1.2.3 After drying, add sodium carboxymethyl starch, micropowder silica gel and magnesium stearate, mix well, and press into tablets. Among them, the diamete...

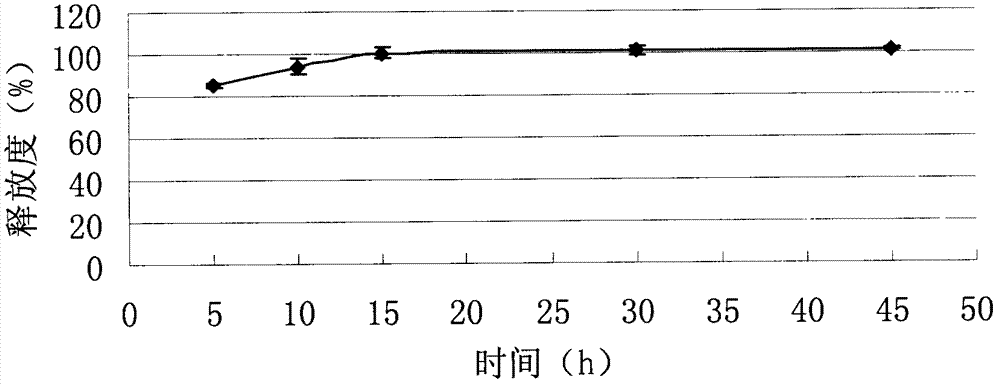

Embodiment 2

[0069] Example 2: Tablet formulation (100 mg tablet)

[0070] 2.1 The formula of imatinib mesylate tablet core in the present embodiment is as shown in Table 3.

[0071] The imatinib mesylate tablet core formula of table 3 embodiment 2 (making 5000 altogether)

[0072]

[0073] 2.2 To prepare the imatinib mesylate tablet core of the above prescription, proceed according to the following steps:

[0074] 2.2.1 Raw materials are air-pulverized, particle size <20um.

[0075] 2.2.2 Add imatinib mesylate, microcrystalline cellulose and croscarmellose sodium into the fluidized bed equipped with top spray equipment as the base, and hydroxypropyl cellulose is dissolved in water to form a mass percentage The mixed liquid with a concentration of 11.8% is sprayed onto the substrate in a fluidized state to form granules. The material temperature is about 35°C for spraying and granulation, and the inlet air temperature is 70°C for drying.

[0076] 2.2.3 After drying, add microcrystall...

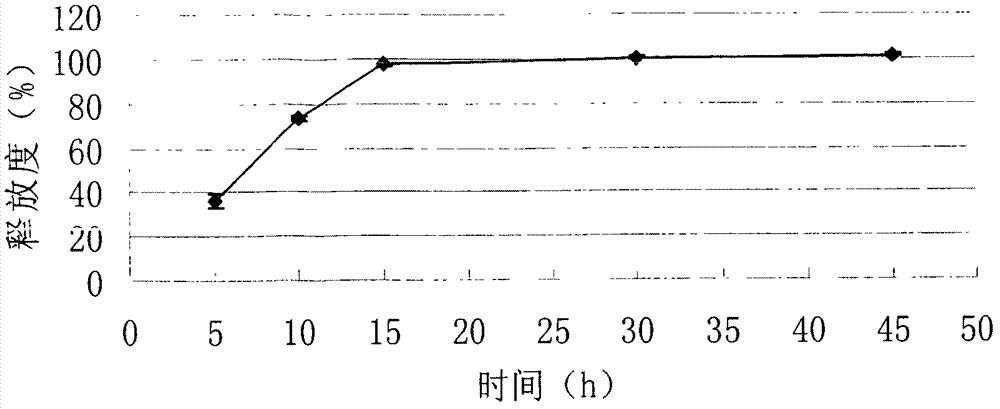

Embodiment 3

[0081] Example 3: Tablet formulation (100 mg tablet)

[0082] 3.1 The formula of imatinib mesylate tablet core in the present embodiment is as shown in Table 5.

[0083] The imatinib mesylate tablet core formula of table 5 embodiment 3 (making 5000 altogether)

[0084]

[0085] 3.2 To prepare the imatinib mesylate tablet core of the above prescription, follow the steps below:

[0086] 3.2.1 Raw materials are air-pulverized, particle size <20um.

[0087] 3.2.2 Mix imatinib mesylate, microcrystalline cellulose and cross-linked polyvinylpyrrolidone evenly, add a hydroxypropyl methylcellulose solution with a mass percentage concentration of 11.1% for rapid stirring and granulation, and obtain a soft material Fluidized bed drying at an inlet air temperature of about 65°C.

[0088] 3.2.3 After drying, add microcrystalline cellulose, cross-linked polyvinylpyrrolidone, micropowder silica gel and magnesium stearate, mix well, and press into tablets. Wherein, the diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com