Porous graphene loaded cerium nano composite antibacterial agent and preparation method thereof

A porous graphene and nanocomposite technology, applied in the directions of botanical equipment and methods, biocides, disinfectants, etc., to achieve the effects of improving stability, reducing use costs, and controlling particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 1 g of graphite powder into 25 mL of concentrated sulfuric acid, cool in an ice-salt bath to 0 °C, and slowly add 2.5 g of KMnO 4 , then heated up to 30 ℃, stirred at 60 rpm for 2 h, added 200 mL of water, then added 2 mL of hydrogen peroxide, centrifuged at 600 rpm to remove impurities, treated with ultrasonic (400 W, 50 Hz) for 1 h, and then microwaved (800 W, 2450 Hz) for 1 h to obtain graphene oxide, then add 5 g NaOH, and heat in a tube furnace at 760 °C for 1 h under nitrogen protection to obtain porous graphene; the specific surface area of porous graphene is 350 m 2 / g; its conductivity is 60 S m -1 ; The weight loss at 900 ℃ is 4 wt%.

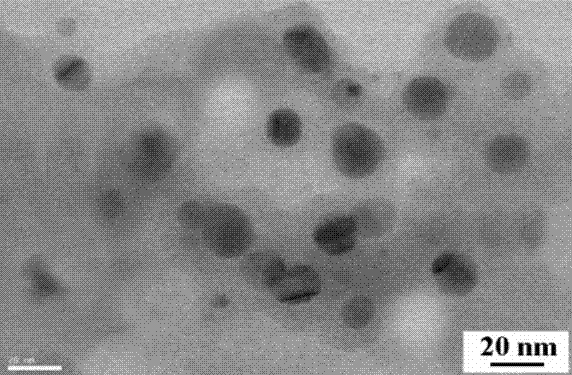

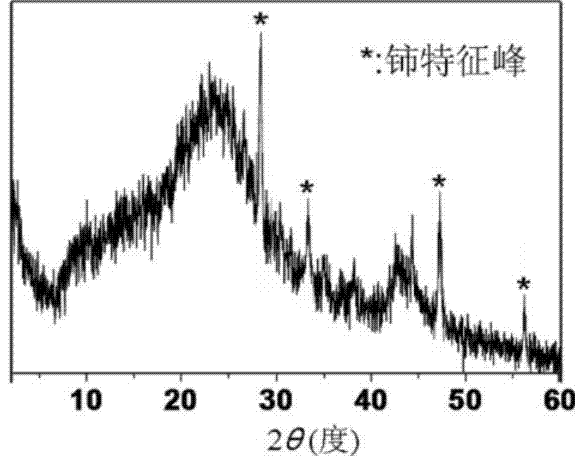

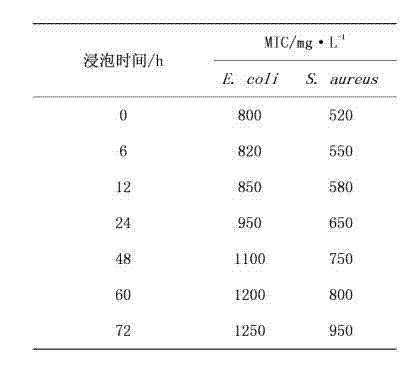

[0023] Take 10 mL of the prepared porous graphene solution (10 mg / mL) and disperse it in 40 mL of ultrapure water, and ultrasonicate the water bath for two hours to obtain a uniform and stable dispersion, then add 43.4 mg of cerium nitrate and oscillate with ultrasonic Until the solution is clear and transparent without ...

Embodiment 2

[0027] Add 1 g of graphite powder into 25 mL of concentrated sulfuric acid, cool in an ice-salt bath to 0 °C, and slowly add 2.6 g of KMnO 4 , then heated up to 30 ℃, stirred at 60 rpm for 2 h, added 200 mL of water, then added 3 mL of hydrogen peroxide, centrifuged at 600 rpm to remove impurities, treated with ultrasonic (400 W, 50 Hz) for 1 h, and then microwaved (800 W, 2450 Hz) for 1 h to obtain graphene oxide, then add 4 g NaOH, and heat in a tube furnace at 760 °C for 1 h under nitrogen protection to obtain porous graphene; the specific surface area of porous graphene is 370 m 2 / g; its conductivity is 50 S m -1 ; The weight loss at 900 ℃ was 4.5 wt%.

[0028] Take 10 mL of the prepared porous graphene solution (10 mg / mL) and disperse it in 40 mL of ultrapure water, and ultrasonicate the water bath for two hours to obtain a uniform and stable dispersion, then add 86.8 mg of cerium nitrate, and oscillate with ultrasonic Until the solution is clear and transparent with...

Embodiment 3

[0031] Add 1 g of graphite powder into 25 mL of concentrated sulfuric acid, cool in an ice-salt bath to 0 °C, and slowly add 2.7 g of KMnO 4 , then heated up to 30 ℃, stirred at 60 rpm for 2 h, added 200 mL of water, then added 2 mL of hydrogen peroxide, centrifuged at 600 rpm to remove impurities, treated with ultrasonic (400 W, 50 Hz) for 1 h, and then microwaved (800 W, 2450 Hz) for 1 h to obtain graphene oxide, then add 3 g NaOH, and heat in a tube furnace at 760 °C for 1 h under nitrogen protection to obtain porous graphene; the specific surface area of porous graphene is 390 m 2 / g; its conductivity is 40 S m -1 ; The weight loss at 900 ℃ is 5 wt%.

[0032] Take 10 mL of the prepared porous graphene solution (10 mg / mL) and disperse it in 40 mL of ultrapure water, and ultrasonicate the water bath for two hours to obtain a uniform and stable dispersion, then add 434 mg of cerium nitrate and oscillate with ultrasonic Until the solution is clear and transparent without p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com