Laser annealing device and laser annealing method

A laser annealing and laser technology, applied in laser welding equipment, electrical components, circuits, etc., can solve problems such as low beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Next, examples of the present invention will be described in comparison with comparative examples.

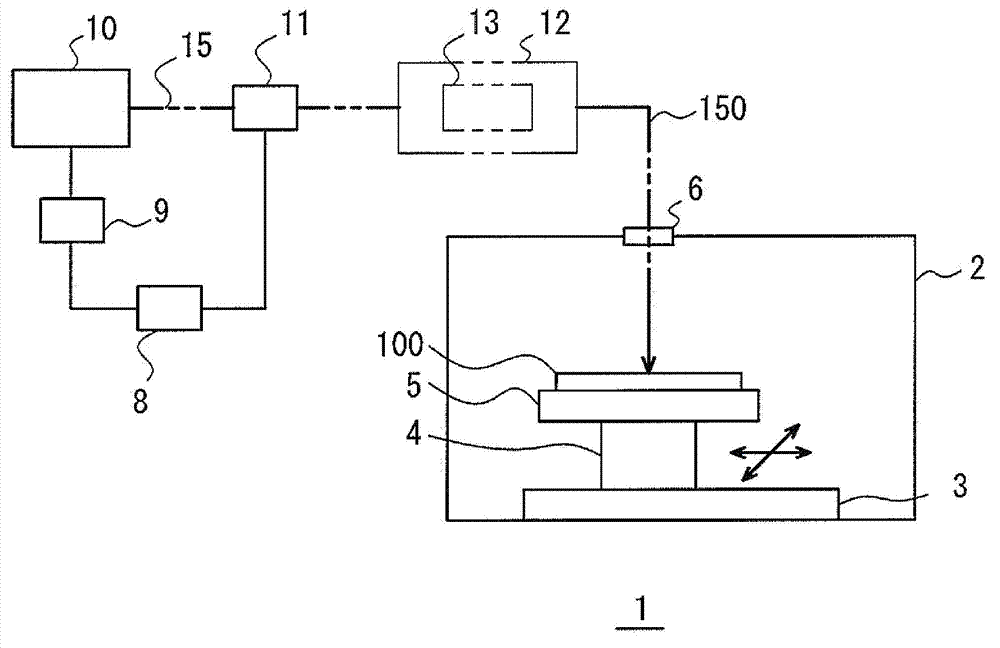

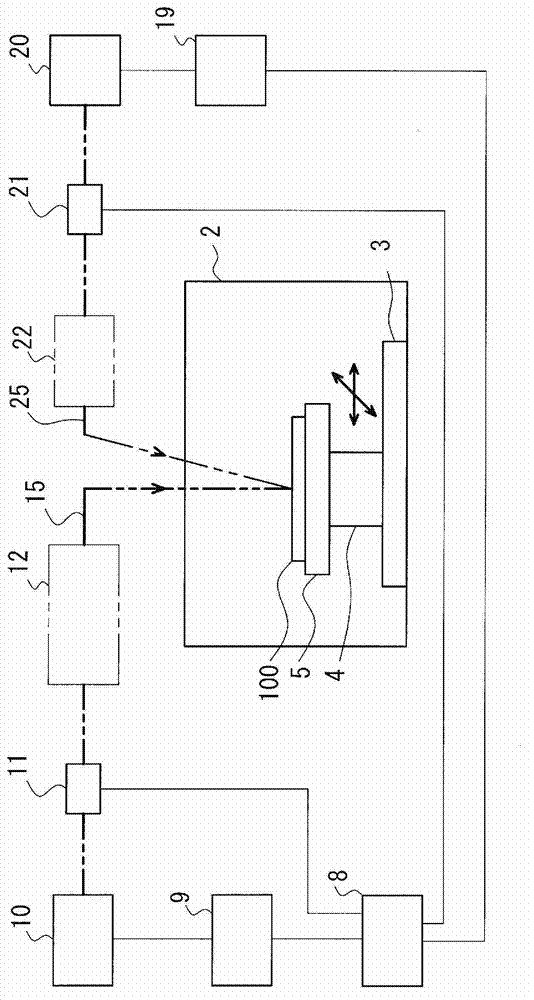

[0096] Utilize the laser annealing apparatus of above-mentioned embodiment ( figure 1 ), an experiment of irradiating pulsed laser light at 50 nm to an amorphous silicon thin film formed on the surface of a glass substrate by a common method was carried out.

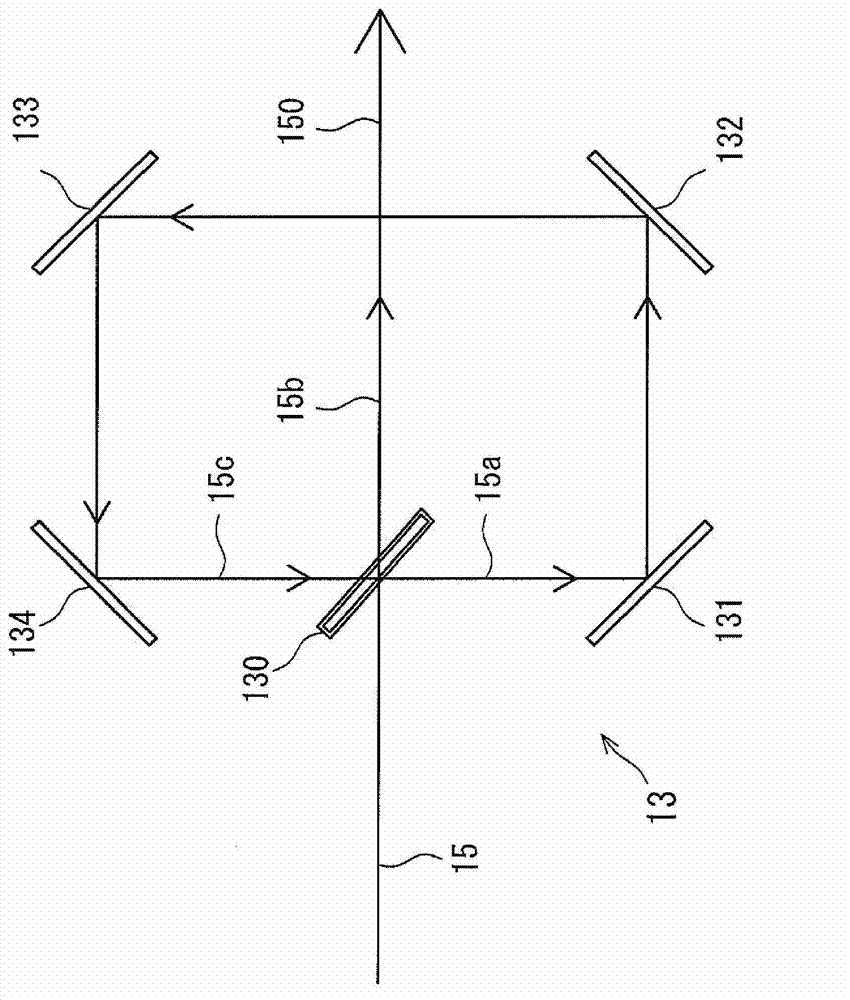

[0097] In this experiment, the pulsed laser was shaped by the light transmission unit so that the processed surface became a rectangle, and the energy density on the irradiated surface was set to be 8-400mJ / cm 2 , The pulse width is in the range of 20-600ns to irradiate the amorphous silicon on the substrate. In addition, the absorption coefficient of the amorphous silicon film is defined as absorption coefficient=4πk / wavelength.

[0098] (k: Attenuation coefficient refers to non-patent literature: D.E.Aspnes and J.B.Theeten, J.Electrochem.Soc.127,1359(1980))

[0099] Amorphous silicon is heated by irradiation ...

Embodiment 2

[0105] If a XeCl excimer laser is used for the laser oscillator, set the effective power density to 2.7×10 12 When irradiated with pulsed laser light, as shown in photo 2, uniform crystals without spots are formed.

Embodiment 3

[0107] If a YAG third harmonic solid-state laser is used for the laser oscillator, set the effective power density to 1.8×10 12 When irradiated with pulsed laser light, as shown in photo 3, uniform crystals without spots are formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com