Light-autocontrolling glass antiexplosion film and light-autocontrolling antiexplosion glass

An explosion-proof film and glass technology, applied in glass/slag layered products, optics, optical components, etc., can solve the problems of colorless transparent glass and colored glass that the transparency cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will further describe in detail with reference to the drawings and the embodiments of the present invention.

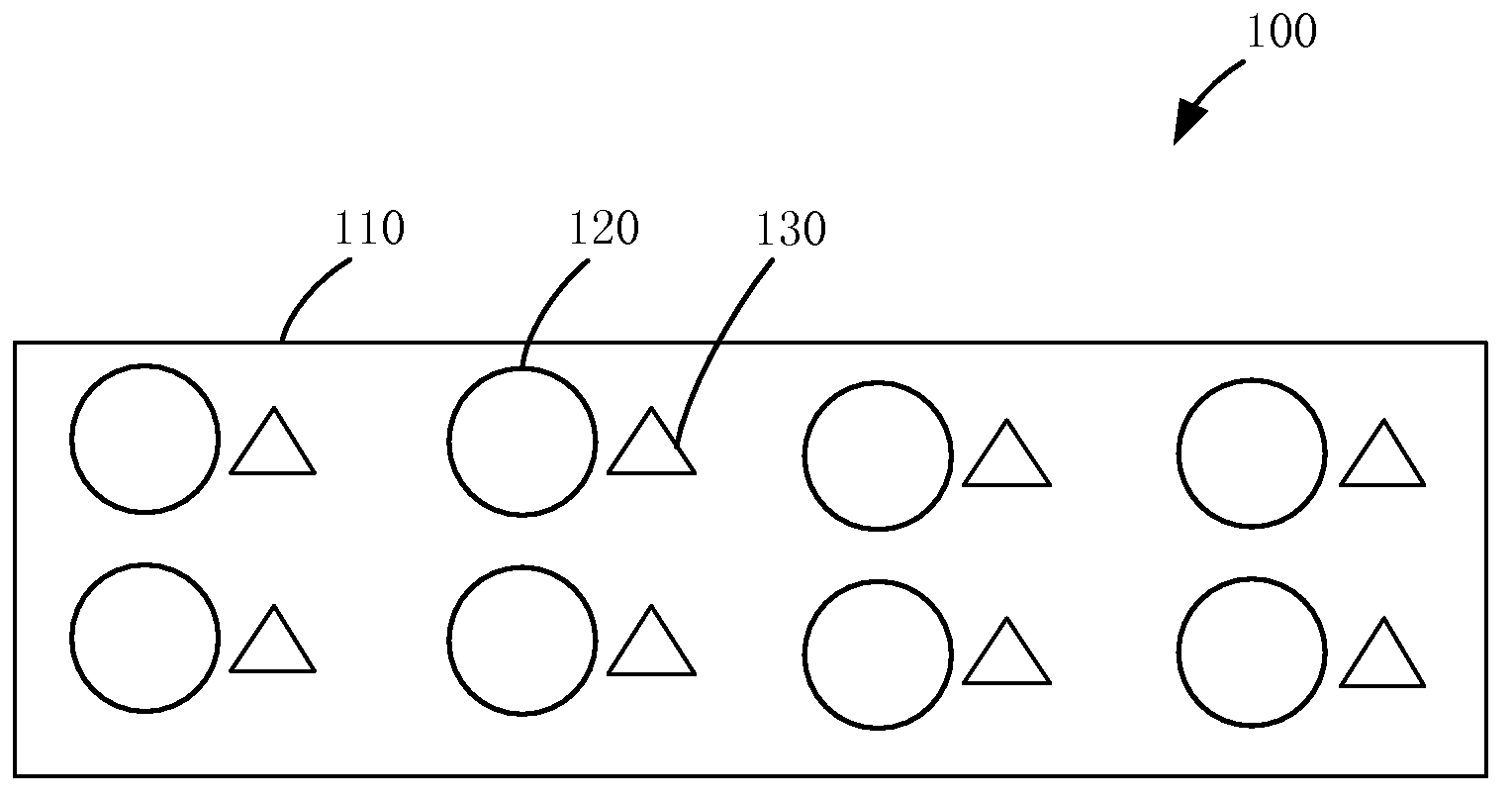

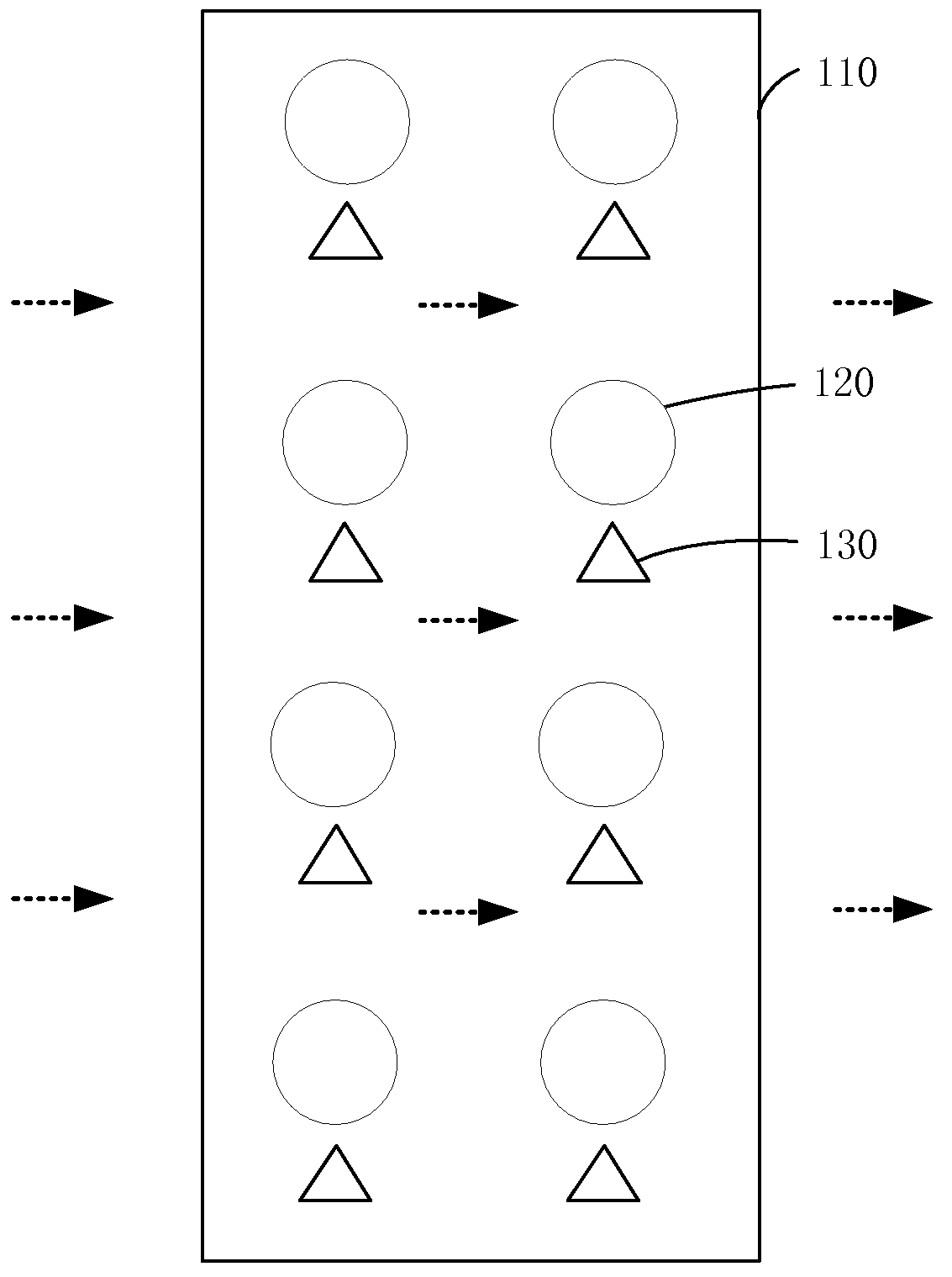

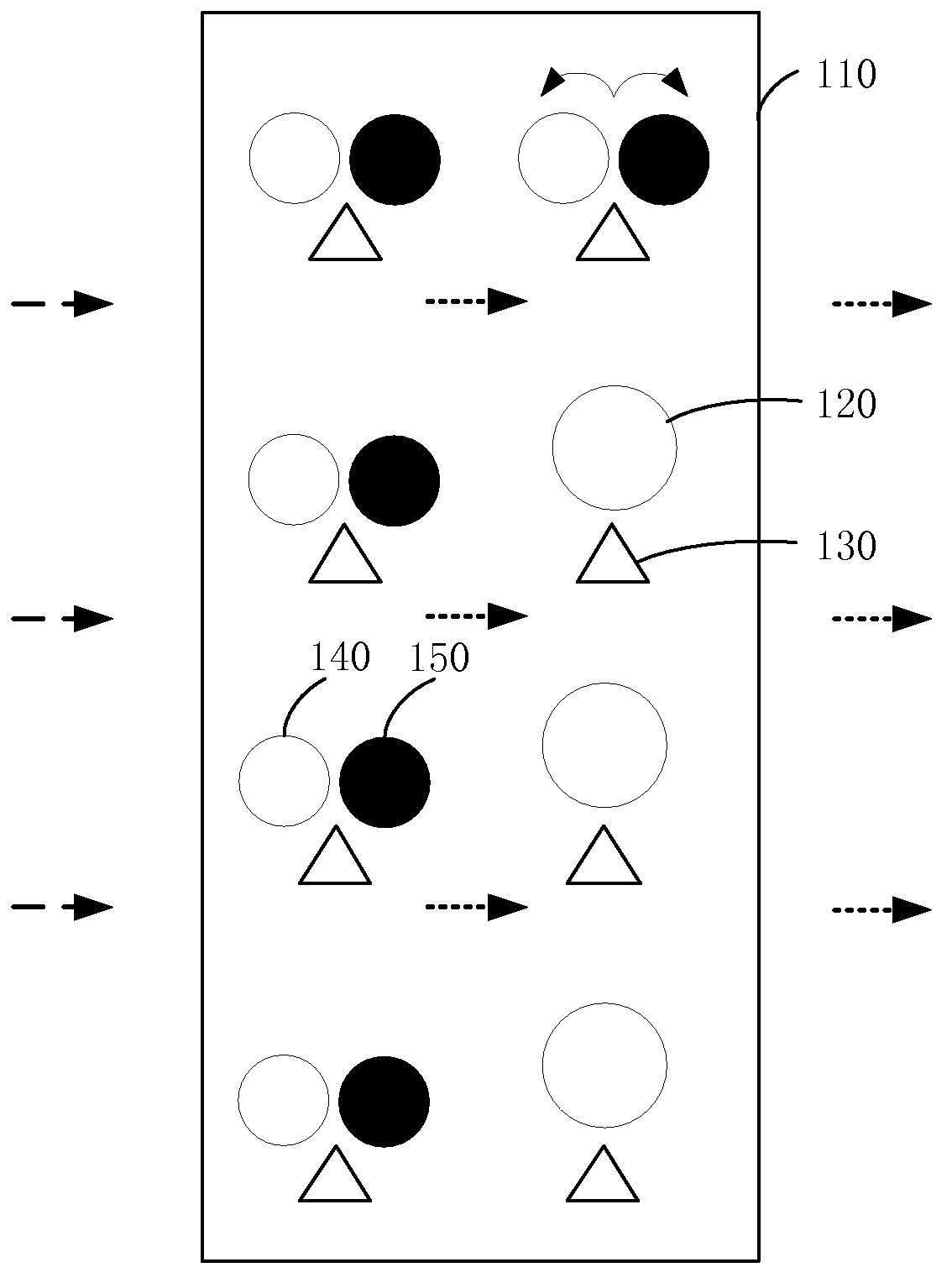

[0027] figure 1 It is a schematic diagram of the structure of the automatic light control glass explosion-proof film 100 provided by the present invention. Such as figure 1 As shown, the automatic light control glass explosion-proof film 100 provided by the present invention includes a Thermoplastics Polymer layer 110, a sensitizer 120, and a sensitizer 130. Wherein, the photosensitive agent 120 is distributed inside the thermoplastic polymer layer 110, and is used to change color with the change of light intensity, thereby changing the transparency of the automatic light control glass explosion-proof film 100. The sensitizer 130 is distributed inside the thermoplastic polymer layer 110 and is used to catalyze the color change of the sensitizer 120 with changes in light intensity.

[0028] In this embodiment, the thermoplastic polymer layer 110 is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com