Phase change heat pipe for satellite payload and instrument board

A technology of instrument board and phase change, which is applied in the field of heat dissipation device, cooling, and temperature uniformity, can solve the problems of difficult balance of satellite load and instrument board temperature, single heat pipe with large volume and weight, etc., and achieve good isothermal performance, small weight index, The effect of large heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

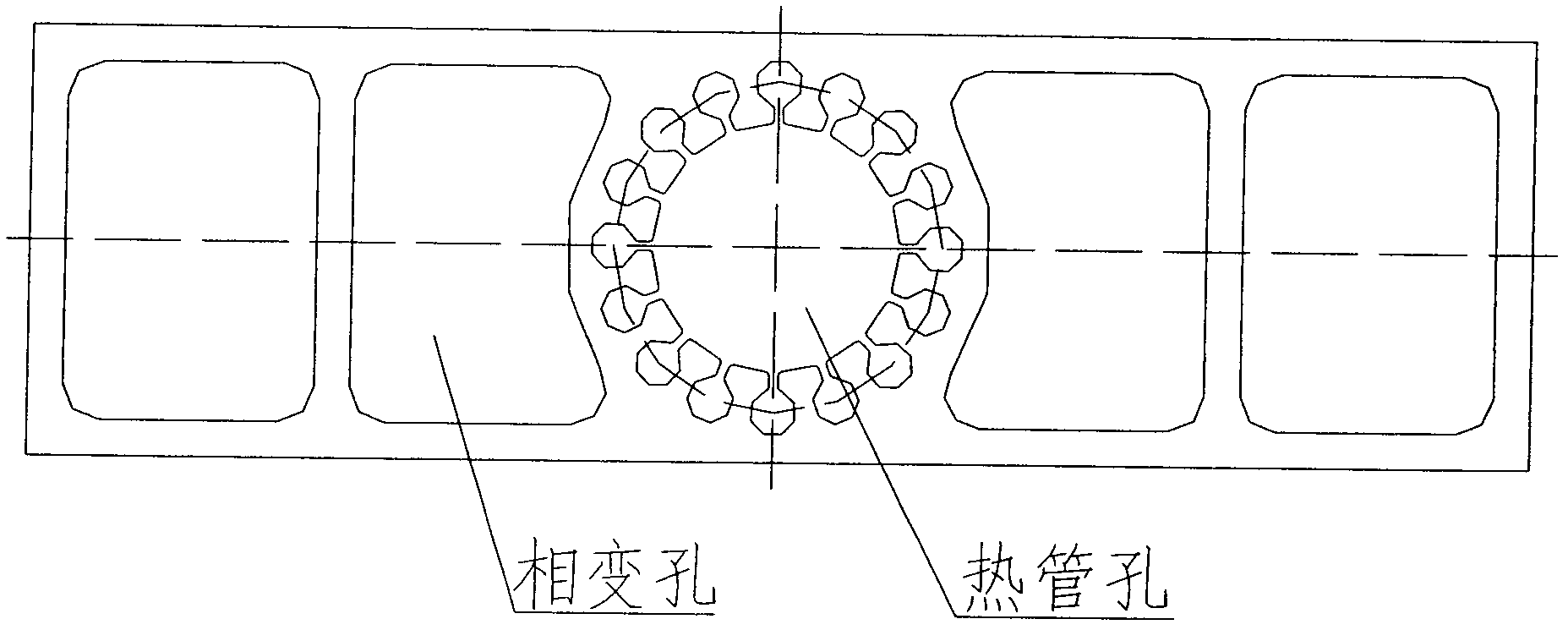

[0013] figure 1 Be the cross-sectional view of phase change heat pipe for satellite load and instrument panel of the present invention, as figure 1 As shown in the embodiment, the device includes:

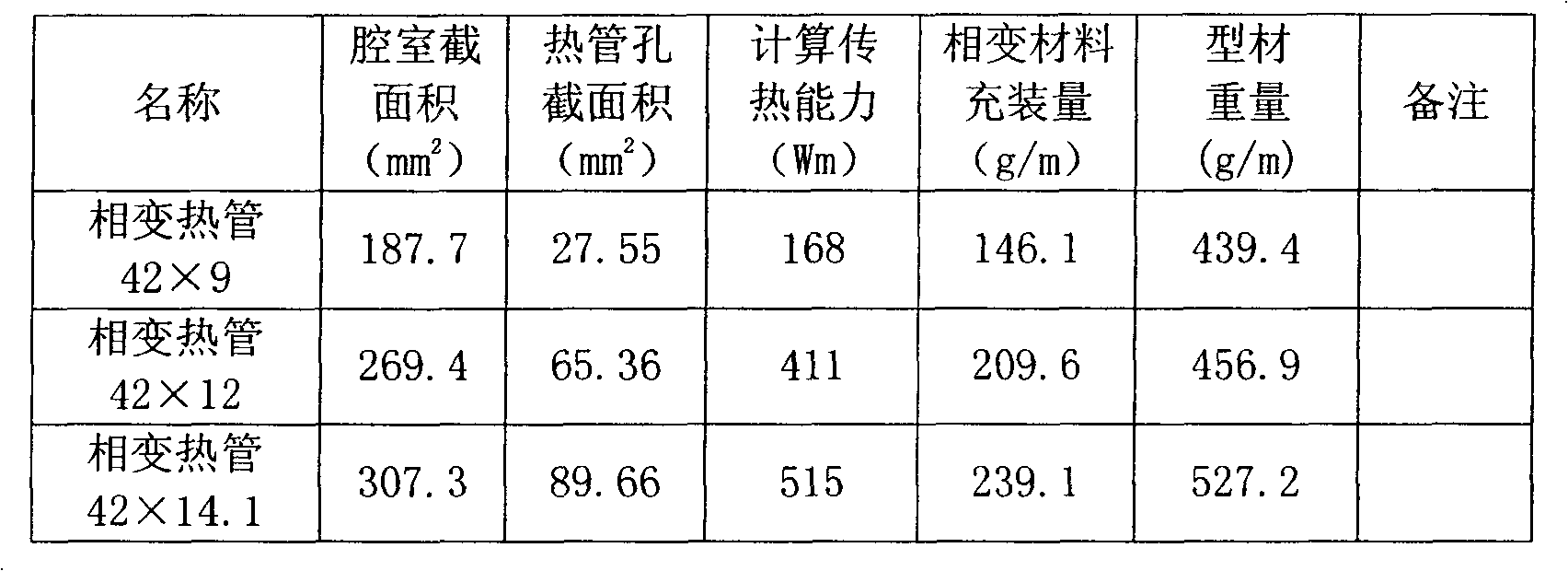

[0014] A rectangular metal aluminum profile, the central area of which is a heat pipe hole with an Ω-shaped axial channel core, at least two axial phase change holes are distributed on both sides of the heat pipe hole, and the phase change material is injected into the phase change hole Sealed to form a phase change material chamber.

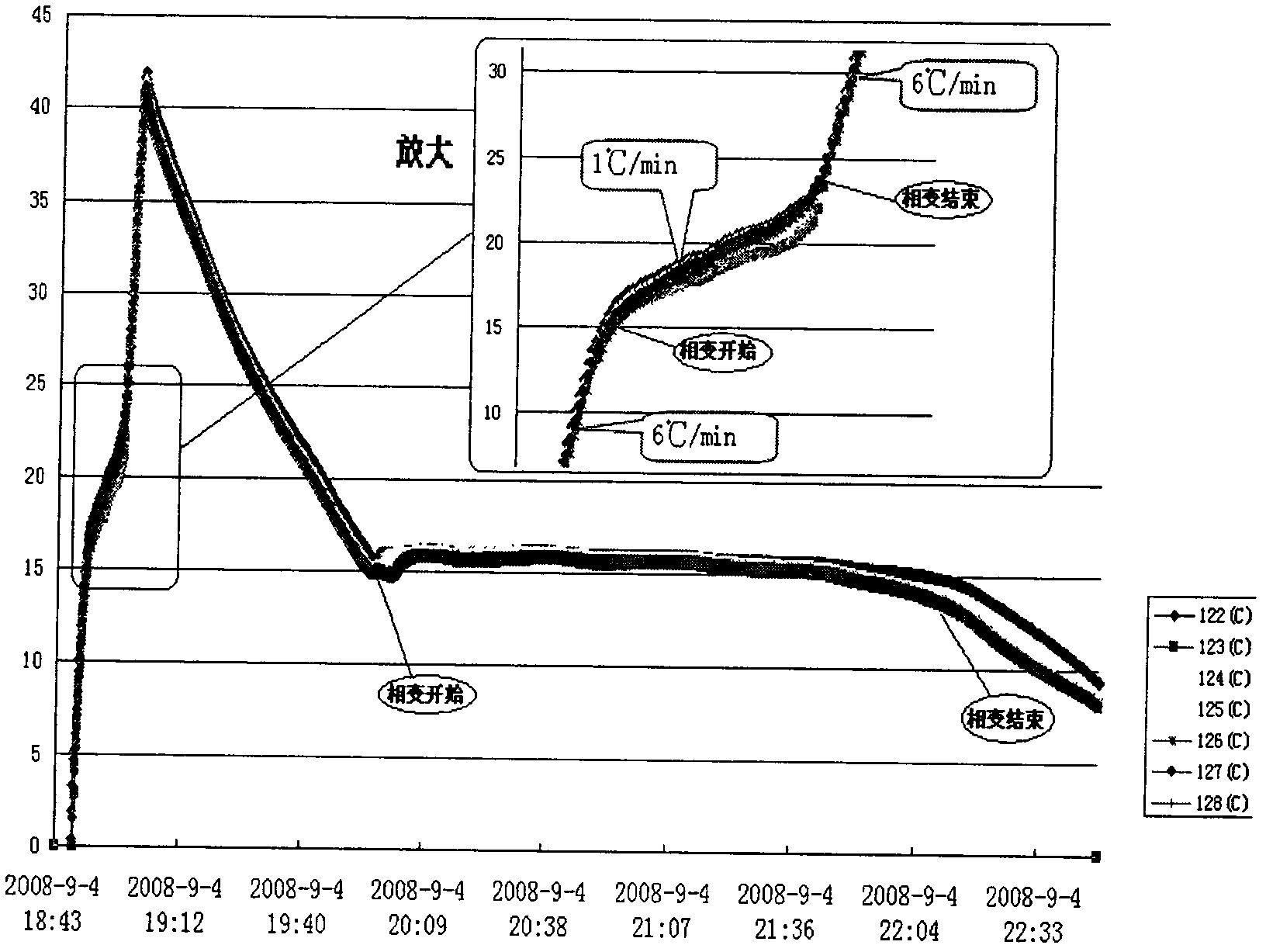

[0015] As mentioned above, the phase change heat pipe of the present invention is formed by combining the heat pipe and the phase change material. It can not only utilize the good isothermal property of the heat pipe, but also utilize the good constant temperature property of the phase change material at the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com