Rare earth cng high pressure bottle filling equipment and bottle filling method for metal cutting and welding

A metal and high-pressure technology, applied in the field of rare earth CNG high-pressure bottle filling equipment and bottle filling for metal cutting and welding, can solve problems such as inability to apply and affect the economic benefit of CNGV gas filling sub-stations in terms of volume utilization rate of steel cylinders, so as to improve the utilization rate, High social and economic benefits, the effect of prolonging the burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

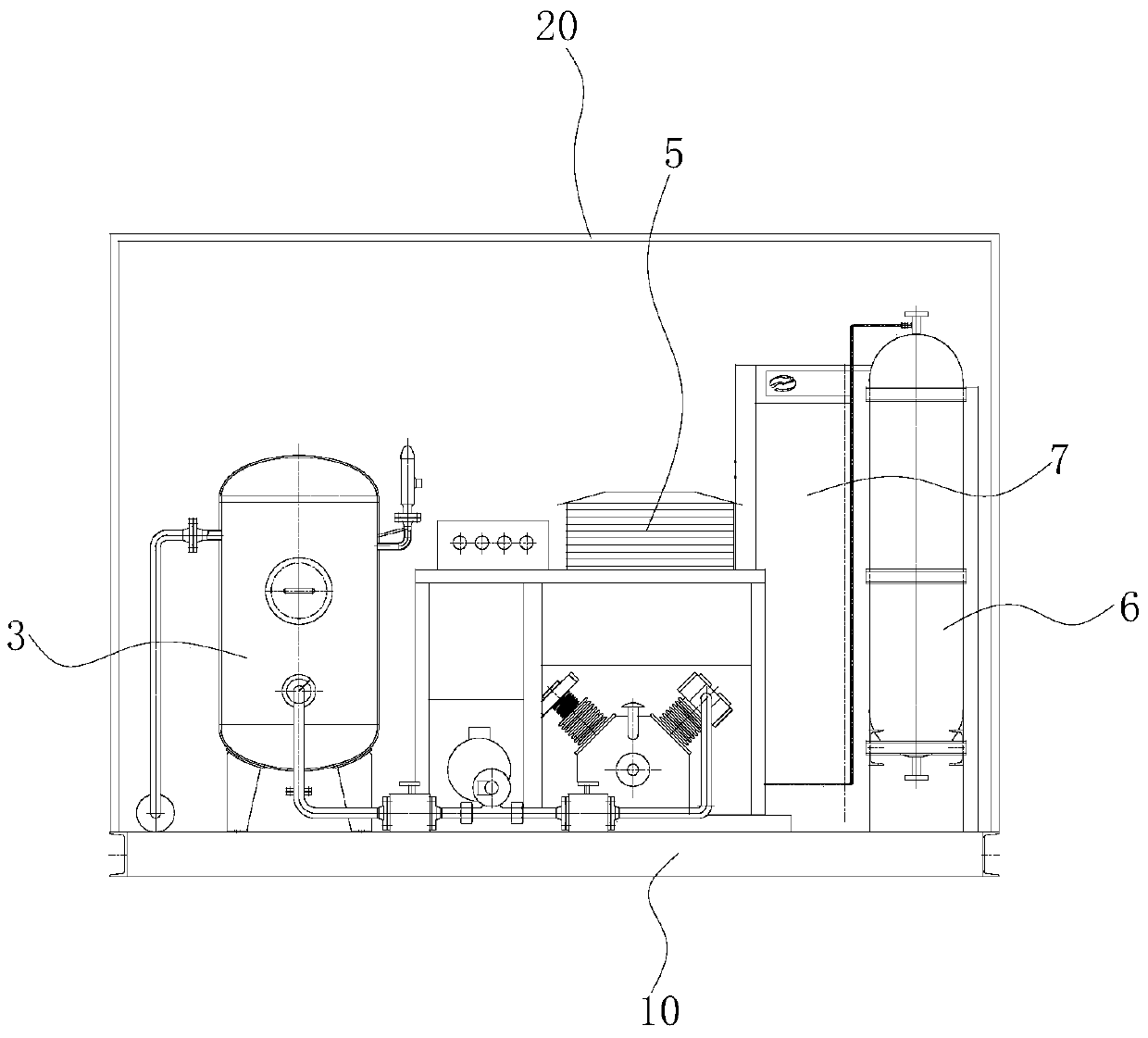

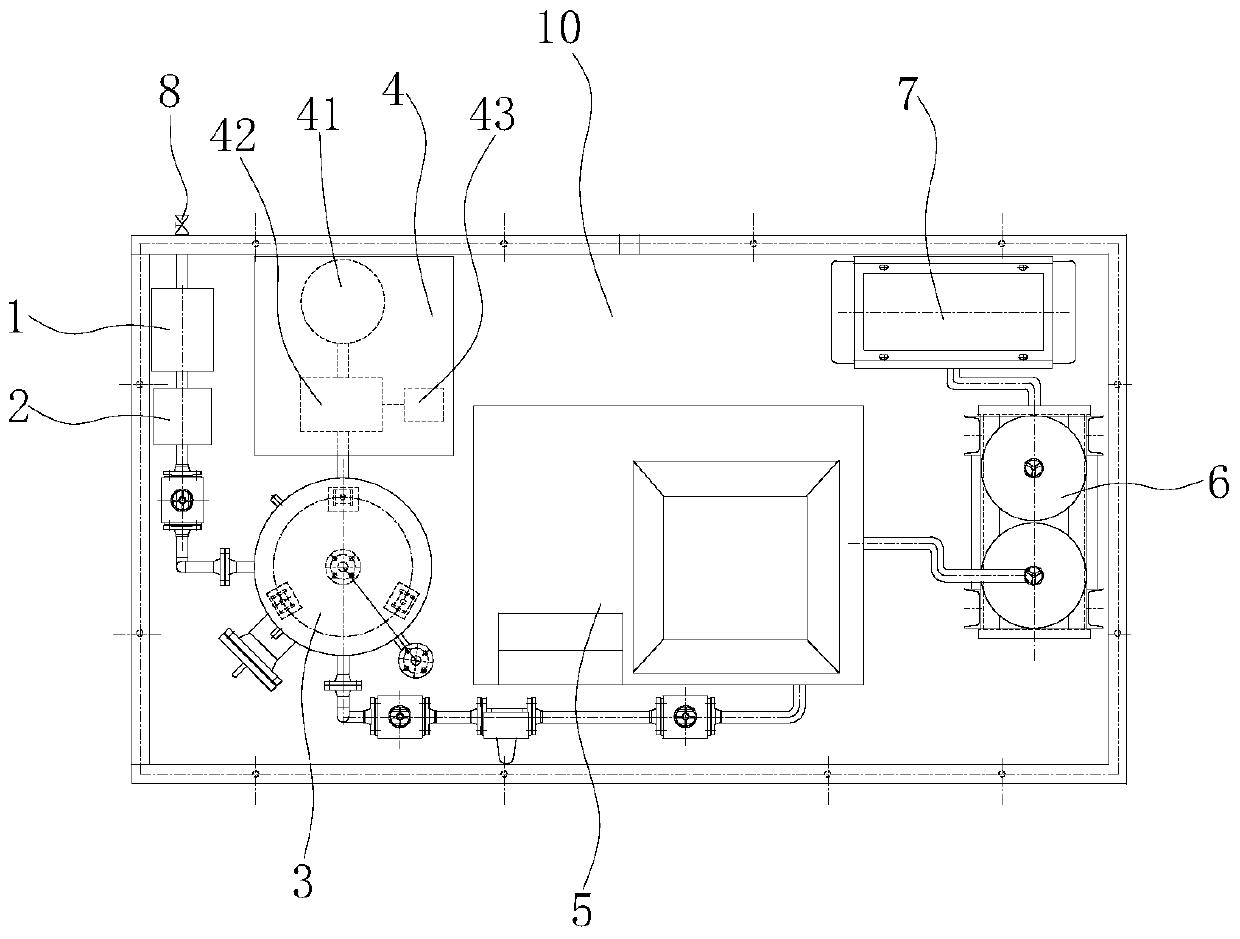

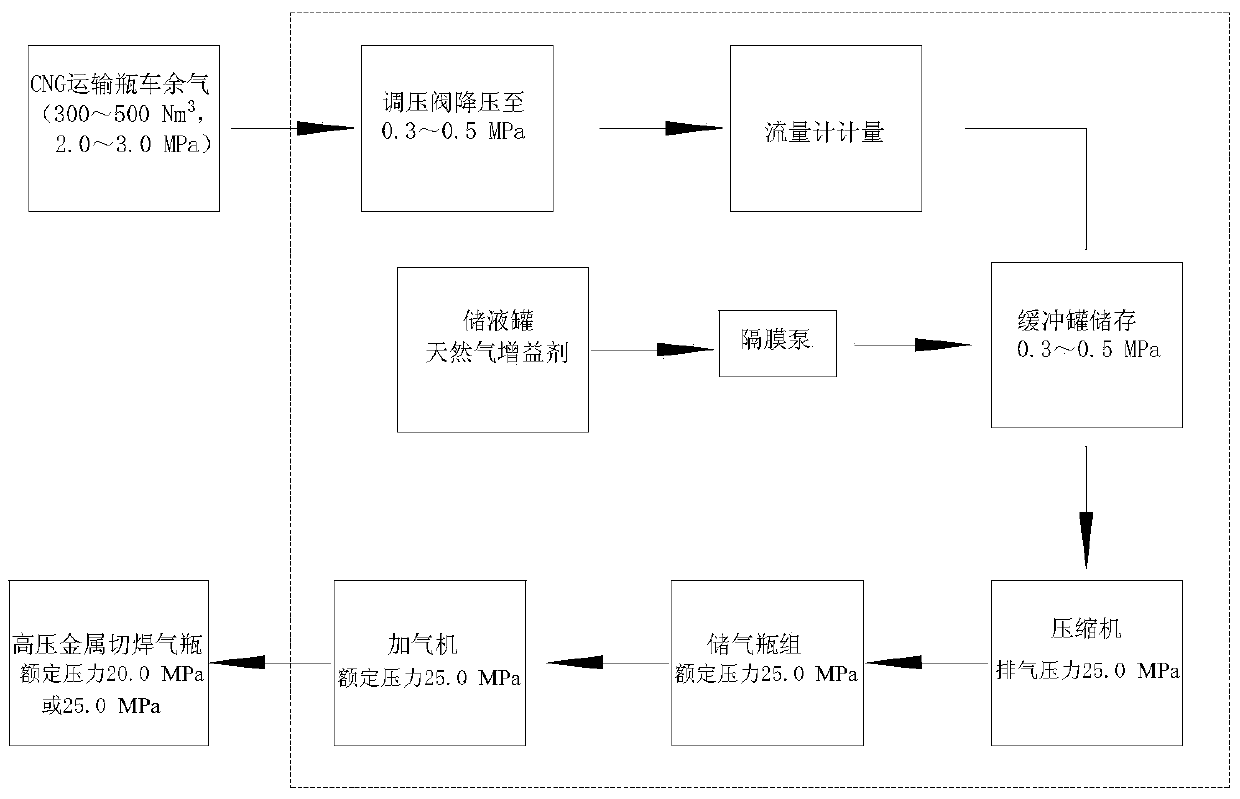

[0023] Rare earth CNG high pressure bottle filling equipment for metal cutting and welding, such as figure 1 with figure 2 As shown, it includes a base 10, a pry body 20, a pressure regulating valve 1, a flow meter 2, a buffer tank 3, a booster filling system 4, a natural gas compressor 5, a gas storage cylinder group 6 and a gas dispenser 7, and a pressure regulating valve The gas outlet of 1 is connected to the pipeline of flowmeter 2, the gas outlet of flowmeter 2 is connected to the air inlet of buffer tank 3, the liquid inlet of buffer tank 3 is connected to the booster system 4, and the gas outlet of buffer tank 3 is connected to the natural gas compression The gas outlet of the natural gas compressor 5 is connected to the gas storage cylinder group 6, and the gas storage cylinder group 6 is connected to the gas filling machine 7. The pressure regulating valve 1, the flow meter 2, the buffer tank 3, and the filling gain The agent system 4, the natural gas compressor 5,...

Embodiment 2

[0036] Rare earth CNG high pressure bottle filling equipment for metal cutting and welding, such as figure 1 with figure 2 As shown, it includes a base 10, a pry body 20, a pressure regulating valve 1, a flow meter 2, a buffer tank 3, a booster filling system 4, a natural gas compressor 5, a gas storage cylinder group 6 and a gas dispenser 7, and a pressure regulating valve The gas outlet of 1 is connected to the pipeline of flowmeter 2, the gas outlet of flowmeter 2 is connected to the air inlet of buffer tank 3, the liquid inlet of buffer tank 3 is connected to the booster system 4, and the gas outlet of buffer tank 3 is connected to the natural gas compression The gas outlet of the natural gas compressor 5 is connected to the gas storage cylinder group 6, and the gas storage cylinder group 6 is connected to the gas filling machine 7. The pressure regulating valve 1, the flow meter 2, the buffer tank 3, and the filling gain The agent system 4, the natural gas compressor 5,...

Embodiment 3

[0048] Rare earth CNG high pressure bottle filling equipment for metal cutting and welding, such as figure 1 with figure 2 As shown, it includes a base 10, a pry body 20, a pressure regulating valve 1, a flow meter 2, a buffer tank 3, a booster filling system 4, a natural gas compressor 5, a gas storage cylinder group 6 and a gas dispenser 7, and a pressure regulating valve The gas outlet of 1 is connected to the pipeline of flowmeter 2, the gas outlet of flowmeter 2 is connected to the air inlet of buffer tank 3, the liquid inlet of buffer tank 3 is connected to the booster system 4, and the gas outlet of buffer tank 3 is connected to the natural gas compression The gas outlet of the natural gas compressor 5 is connected to the gas storage cylinder group 6, and the gas storage cylinder group 6 is connected to the gas filling machine 7. The pressure regulating valve 1, the flow meter 2, the buffer tank 3, and the filling gain The agent system 4, the natural gas compressor 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com