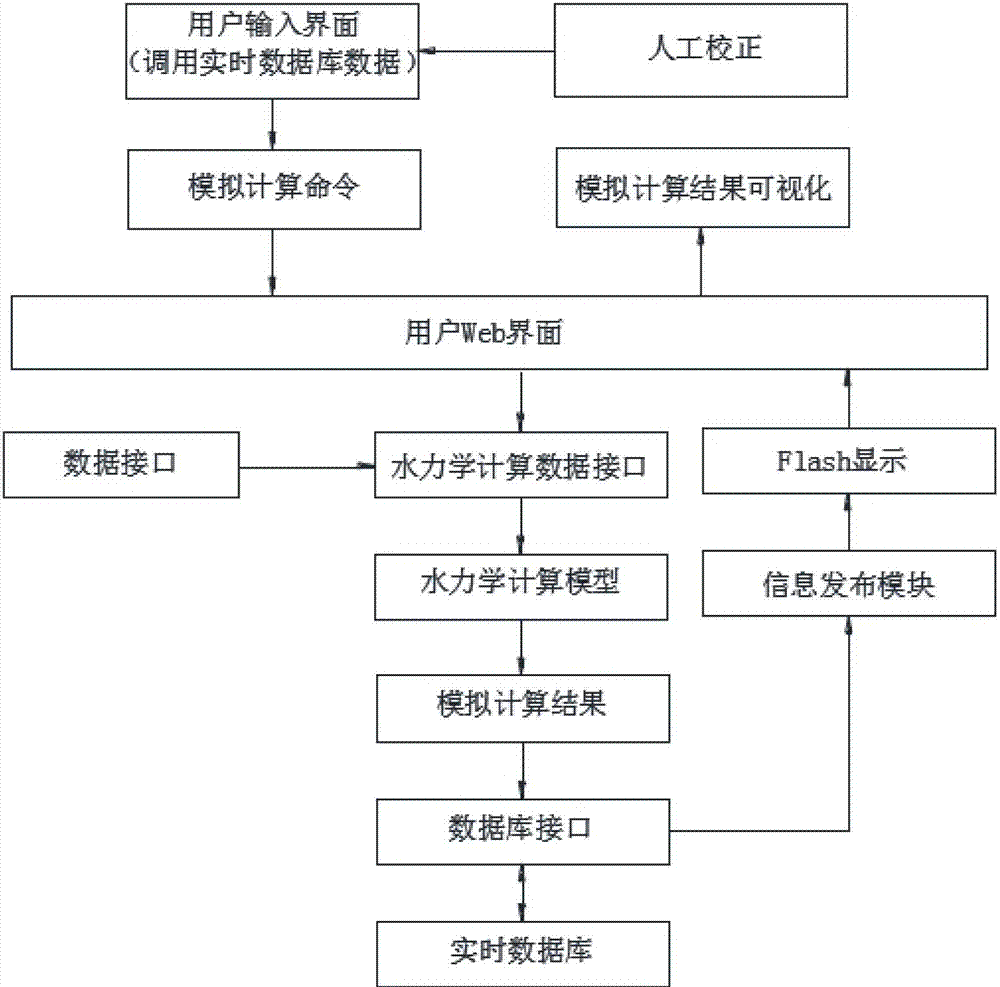

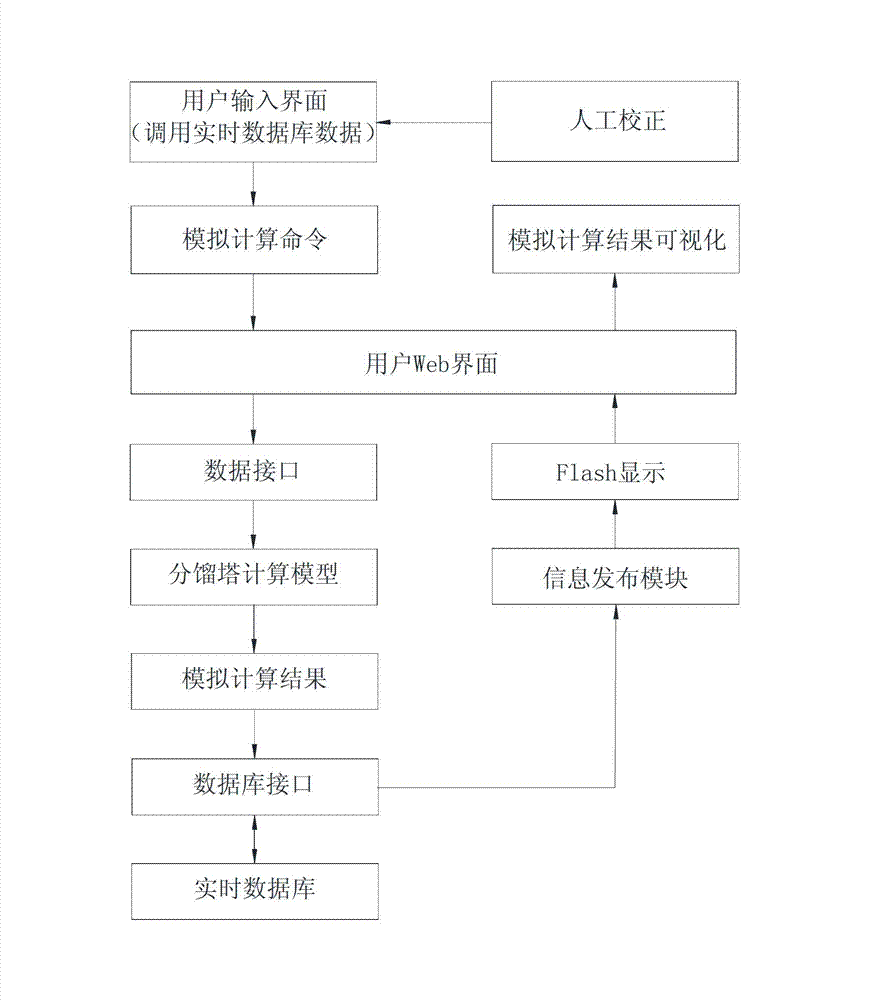

Catalytic cracking transparent fractionating tower simulation calculation system based on process simulation software

A simulation calculation and process simulation technology, applied in the field of catalytic cracking transparent fractionation tower simulation calculation system, can solve the problems of incompletely accurate new changes in the reaction process, failure to reflect the database system, and failure to reflect the real-time operation of the fractionation tower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0022]

[0023]

[0024]

[0025] According to the above, the user will collect the basic parameters, product property parameters, raw material parameters and hydraulic parameters (downcomer area percentage 10%, open hole area percentage 23%, tray spacing 0.9m, tower diameter 6m) and other data through Aspen The Plus ActiveX data interface is transmitted to the model of the catalytic cracking fractionation tower, and the calculation program is started. The temperature of the oil and gas at the top of the tower is 112.29°C, the flow rate of -10# diesel oil is 36.41t / h, and the flow rate of 0# diesel oil is 24.55t / h. The slurry flow rate is 14.38t / h, the 90% boiling point of 0# diesel oil is 326°C, and the operating point is in the suitable operating area. The data monitored by DCS is the oil gas temperature at the top of the tower is 115°C, the flow rate of -10# diesel oil is 36.41t / h, the flow rate of 0# diesel oil is 25t / h, the flow rate of oil slurry at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com