Defect detection method and device for display panel

A display panel and detection method technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, and can solve the problems of difficult resolution, easy missed detection of optical defect inspection machines, and reduced detection capabilities of display panels, etc. problems, to prevent missed inspections and improve defect detection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

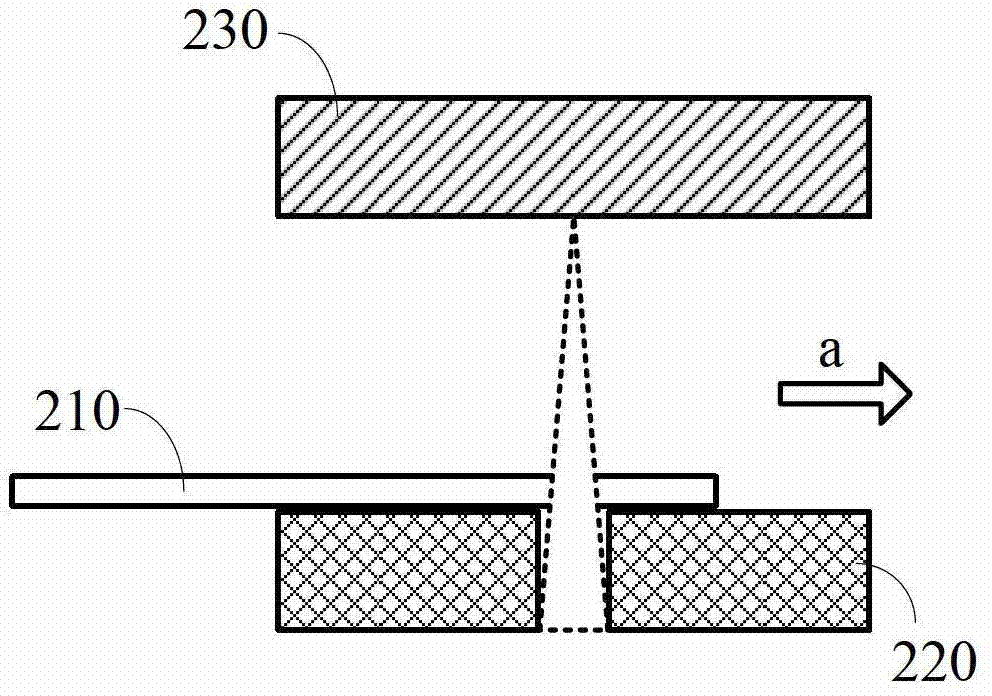

[0026] The invention provides a defect detection method of a display panel and a detection device thereof. Specifically, the defect detection method of the present invention mainly sequentially irradiates the display panel with light of a variety of different colors, and obtains a plurality of corresponding grayscale images, and then judges and detects defects with grayscale differences according to the grayscale differences in the grayscale images. display panel. Among them, the defects include pixel particle shedding, uneven pixel distribution, water residue and ITO residue and other types of display defects, and the gray scale response of each type of defect is different when different colors of light illuminate the display panel.

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] figure 1 It is a schematic flowchart of an embodiment of a defect detection method for a display panel of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com