Key cap drawing force testing device for thin keyboard

A testing device and technology of pulling force, which is applied in the field of key cap pulling force testing device, can solve the problems of inability to distinguish the force supply, affect the service life of the vacuum pump, and small space, and achieve the effect of avoiding work influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

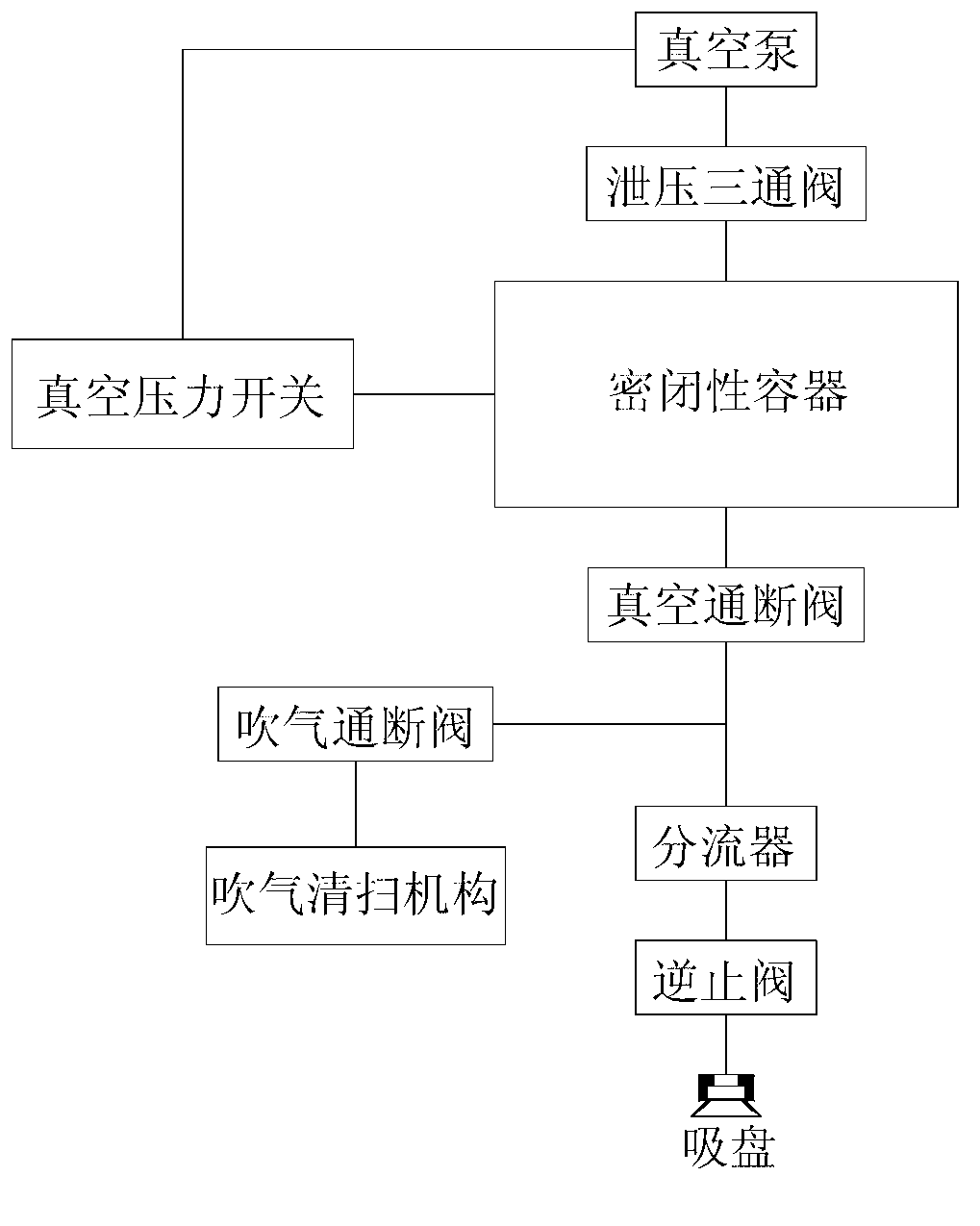

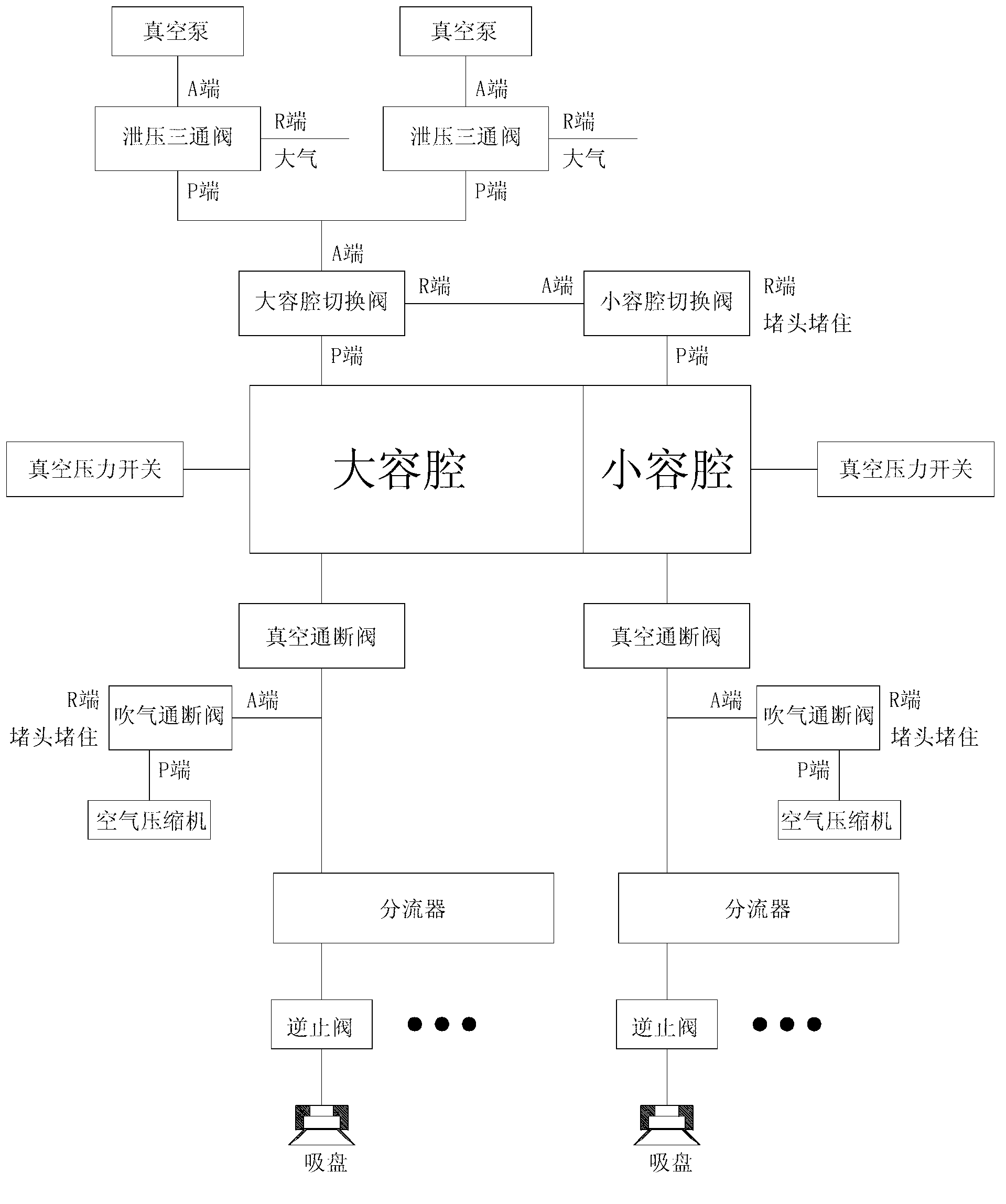

[0033] Such as figure 1 Shown is a thin keyboard keycap pullout test device, including a vacuum pump, pressure relief three-way valve, airtight container, vacuum on-off valve, flow divider, several suction cup air circuits, vacuum pressure switch, blowing and cleaning mechanism and the blowing on-off valve, the suction cup air circuit includes a check valve and a suction cup; the vacuum pump is connected to the A end of the pressure relief three-way valve, the R end of the pressure relief three-way valve is connected to the atmosphere, and the P end of the pressure relief three-way valve is connected to the atmosphere. The end is connected to the vacuum port of the airtight container, and the suction port of the airtight container is connected to the air path of the suction cup through the vacuum on-off valve and the flow divider in turn; the sensing end of the vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com