Circular cut testing method for working stress of concrete members

A technology of working stress and detection method, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of affecting accuracy, early release of local stress, large size of load-bearing components, etc., to achieve convenient application, small damage, and avoid stress loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

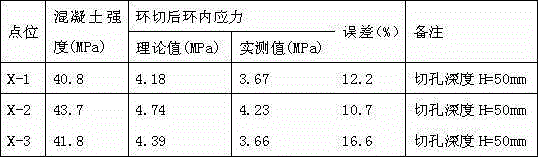

[0017] First determine the detection point of the concrete component, generally select the middle part of the component, use the rebound meter to measure the concrete strength index on the surface of the detection area, so as to determine the elastic modulus E of the concrete; select the 8mm specification resistance strain gauge in the ring cut range according to the direction of the component force Paste firmly, and make waterproof treatment, connect the external resistance strain gauge with the transmission wire, read the strain value ε0, then disconnect the wire, and use concrete circumcision equipment at the detection point (it is not necessary to develop special circumcision equipment, use conventional concrete extraction equipment) core machine) for circumcision operation, the depth of circumcision is 50mm, and the diameter of circumcision is 100mm. Exit the equipment after ring cutting, connect the wire to measure the strain value ε1, control the time interval between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com