Combined construction structure

A technology of building structure and keel, applied in building components, building structure, construction and other directions, can solve the problems of increased consumption, complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

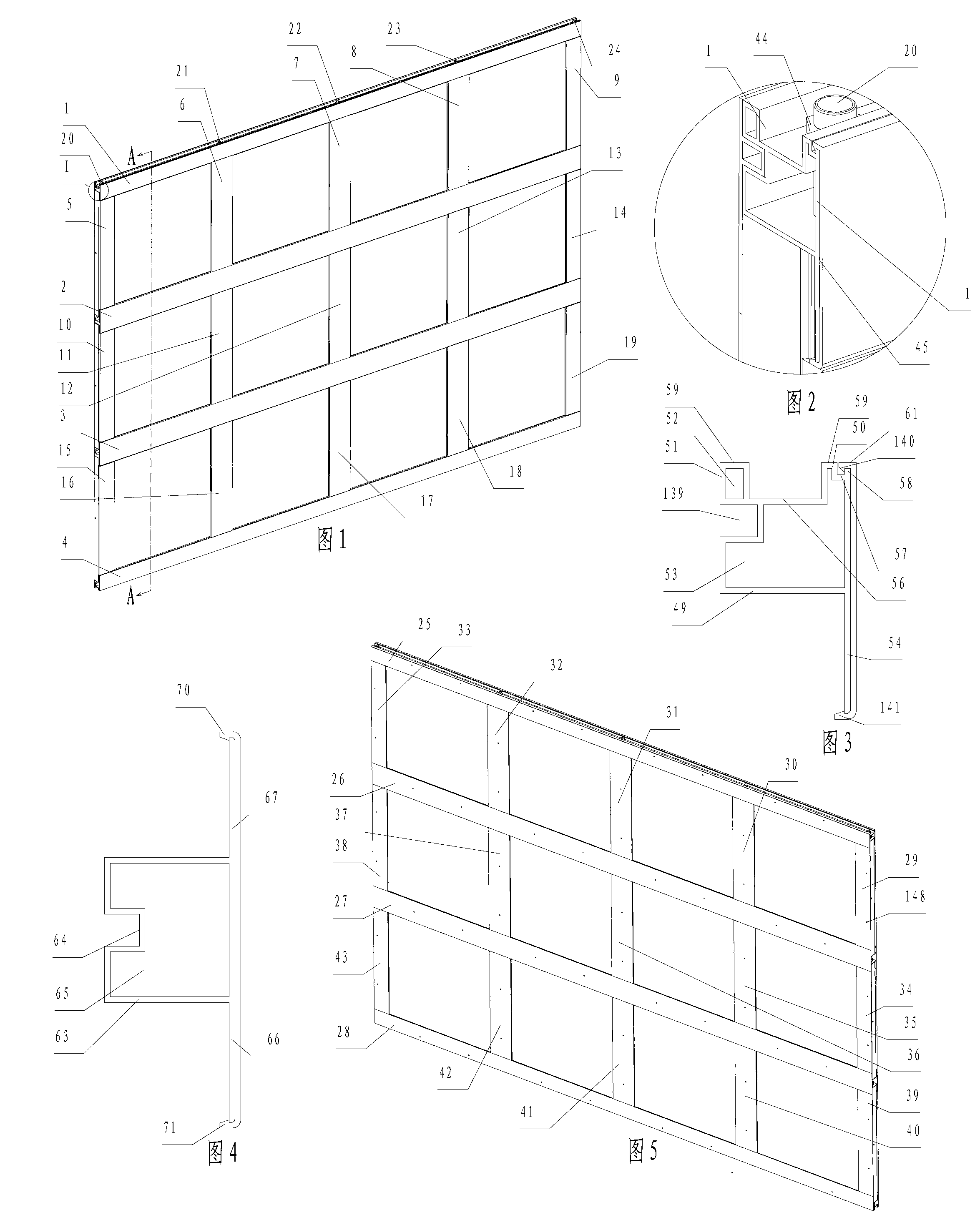

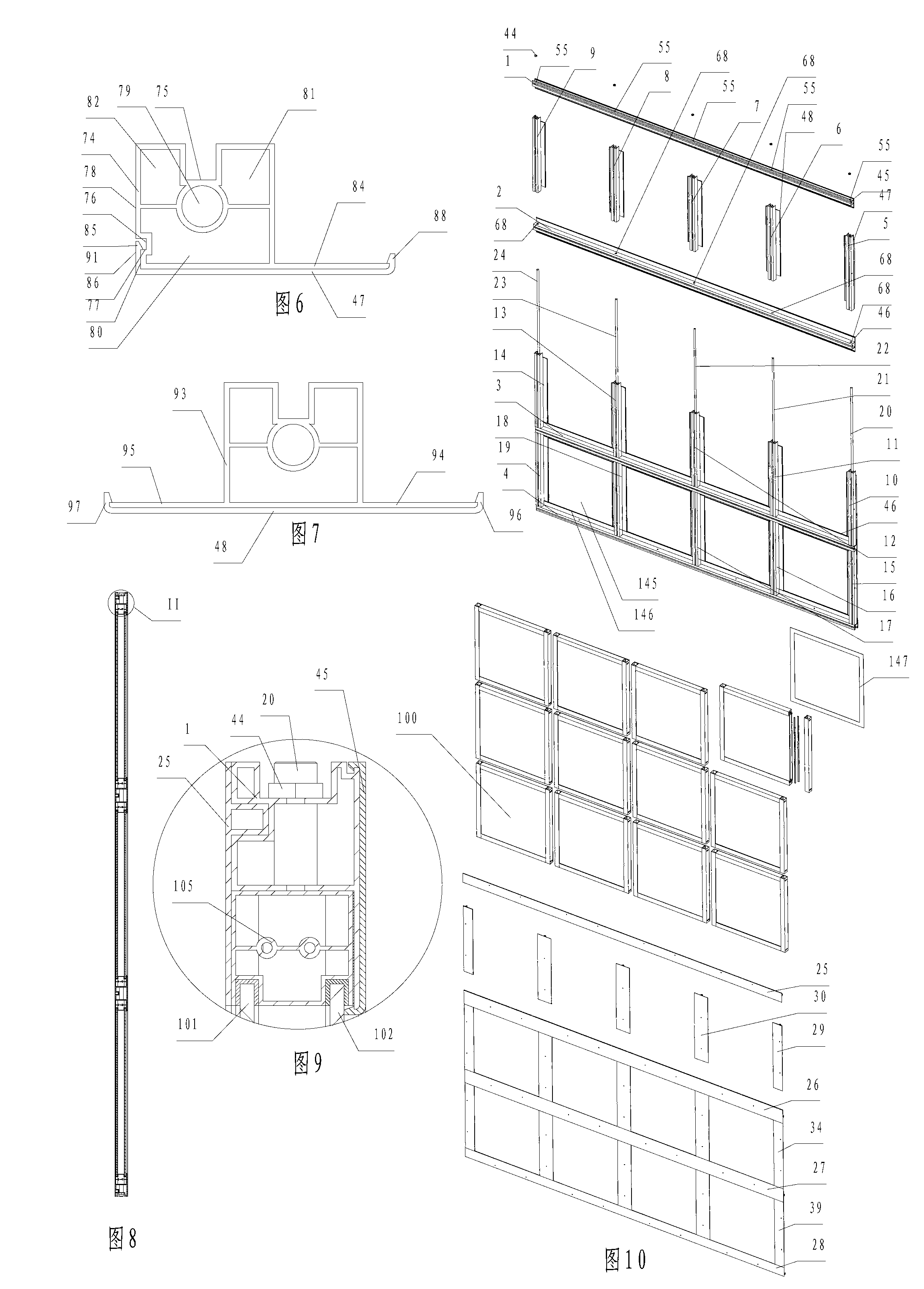

[0119] Such as figure 1 , Figure 10 As shown, a combined building structure is a combined wall structure, including the first keel 1 installed with the first outer spacer 45 in the vertical direction array from top to bottom, and the first outer spacer 46 with the same structure. And the first keel 2 and the first keel 3 with the same structure, the first keel 4 that is installed with the first outer spacer 45 with respect to the horizontal plane of the center position of the symmetry of the first keel 4, is installed on the first keel 1 and the first keel 2 Between, perpendicular to the first keel 1 and the first keel 2, the second keel 5 with the second outer spacer 47 installed vertically in the horizontal direction from left to right, the second outer spacer 48 with the same structure is installed and The second keel 6, the second keel 7 and the second keel 8 with the same structure, the second keel 9 of the second outer spacer 9 that is symmetrical with the second outer...

Embodiment 2

[0136] Different from Embodiment 1, there are four first keels installed vertically, and four second keels are installed horizontally between every two adjacent first keels. Such as Figure 12 , Figure 13 As shown, the rightmost first keel 180 includes a square first keel body 184, which runs through both ends of the first keel body 184 up and down, and is provided with a first card slot 185 in cooperation with the first outer spacer 186. The first keel body The right side 189 of 184 protrudes from the right side 188 of the first card slot 185 close to the groove wall on the outdoor side, and runs through the two ends of the first keel body 184 up and down, so that the wall thickness of the first keel body 184 is relatively uniform. The hole 190 is perpendicular to the left side of the first keel body 184 and protrudes from the side 191 that is flush with the surface of the first keel body 184 facing the outside. .

[0137] Such as Figure 12 , Figure 14 As shown, the f...

Embodiment 3

[0147] The difference from embodiment 2 is that all the first keel and the second keel are plastic profiles, and all the first outer spacer and the second outer spacer are metal parts.

[0148] Such as Figure 19 , Figure 20 As shown, all the first decorative strips and the second decorative strips are flat metal parts. On the side of the square first keel body 261 of the first keel 260 on the right side facing the room, a decorative raised strip 262 flush with the right side of the first keel body 261 is provided, so that the wall thickness of the first keel 260 is relatively uniform. The hollowed through hole 263 runs through the first keel body 261 and the decorative convex strip 262 . The leftmost first keel 264 is symmetrical to the rightmost first keel 260 with respect to the vertical plane at their center positions.

[0149] Such as Figure 19 , Figure 21 As shown, on the side of the square second keel body 266 facing the interior of the three second keel 265 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com